bodgermatic

Established Member

I'm out of my depth here people, and I know there's the knowledge here to put me straight  Over winter I've been relegated to the house because my workshop is uninsulated, and basically uninsulatable. It's a concrete prefab garage, with a low mono pitch roof (front to back) made from corrugated sheets (clear plastic and bitumen), fixed onto steel purlins. The roof is also a little bit low for my tastes, me being 6'2".

Over winter I've been relegated to the house because my workshop is uninsulated, and basically uninsulatable. It's a concrete prefab garage, with a low mono pitch roof (front to back) made from corrugated sheets (clear plastic and bitumen), fixed onto steel purlins. The roof is also a little bit low for my tastes, me being 6'2".

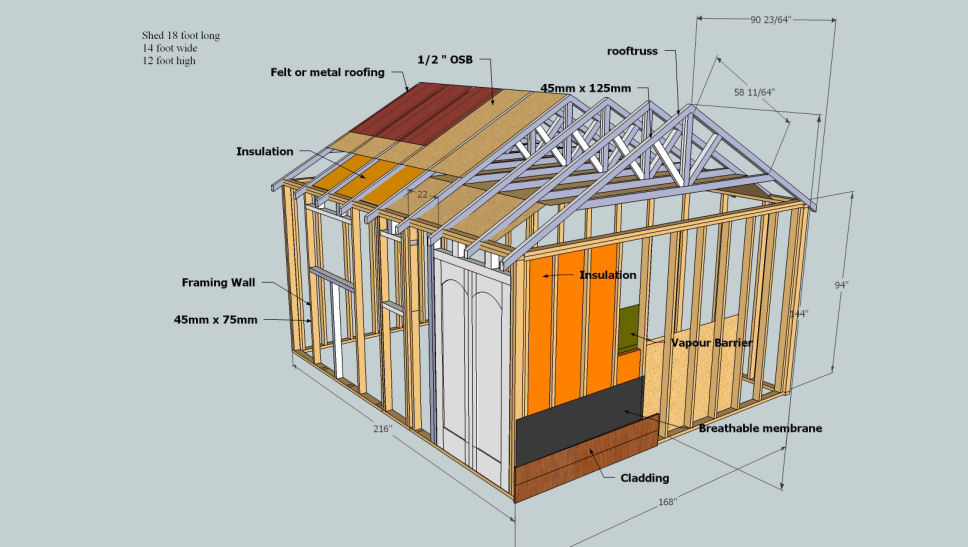

I'd like to replace the roof with a duo pitched one, with a higher ridge, but I've no idea how to go about designing one or making sure that the building can bear the weight. The image below shows the prefab walls, the wooden doors I built at the front, and the metal purlins which are bolted across and give some rigidity to the overall structure.

Ideally I'd like to get rid of the purlins, because they are only just above my head height, but I'm concerned that they're essential to keeping the walls up! I've sort of imagined that I could build a wooden framework inside the prefab panels which would actually bear the weight of the roof, but this would need to be quite thin to avoid losing too much space from the inside.

Cheers folks!

I'd like to replace the roof with a duo pitched one, with a higher ridge, but I've no idea how to go about designing one or making sure that the building can bear the weight. The image below shows the prefab walls, the wooden doors I built at the front, and the metal purlins which are bolted across and give some rigidity to the overall structure.

Ideally I'd like to get rid of the purlins, because they are only just above my head height, but I'm concerned that they're essential to keeping the walls up! I've sort of imagined that I could build a wooden framework inside the prefab panels which would actually bear the weight of the roof, but this would need to be quite thin to avoid losing too much space from the inside.

Cheers folks!