You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

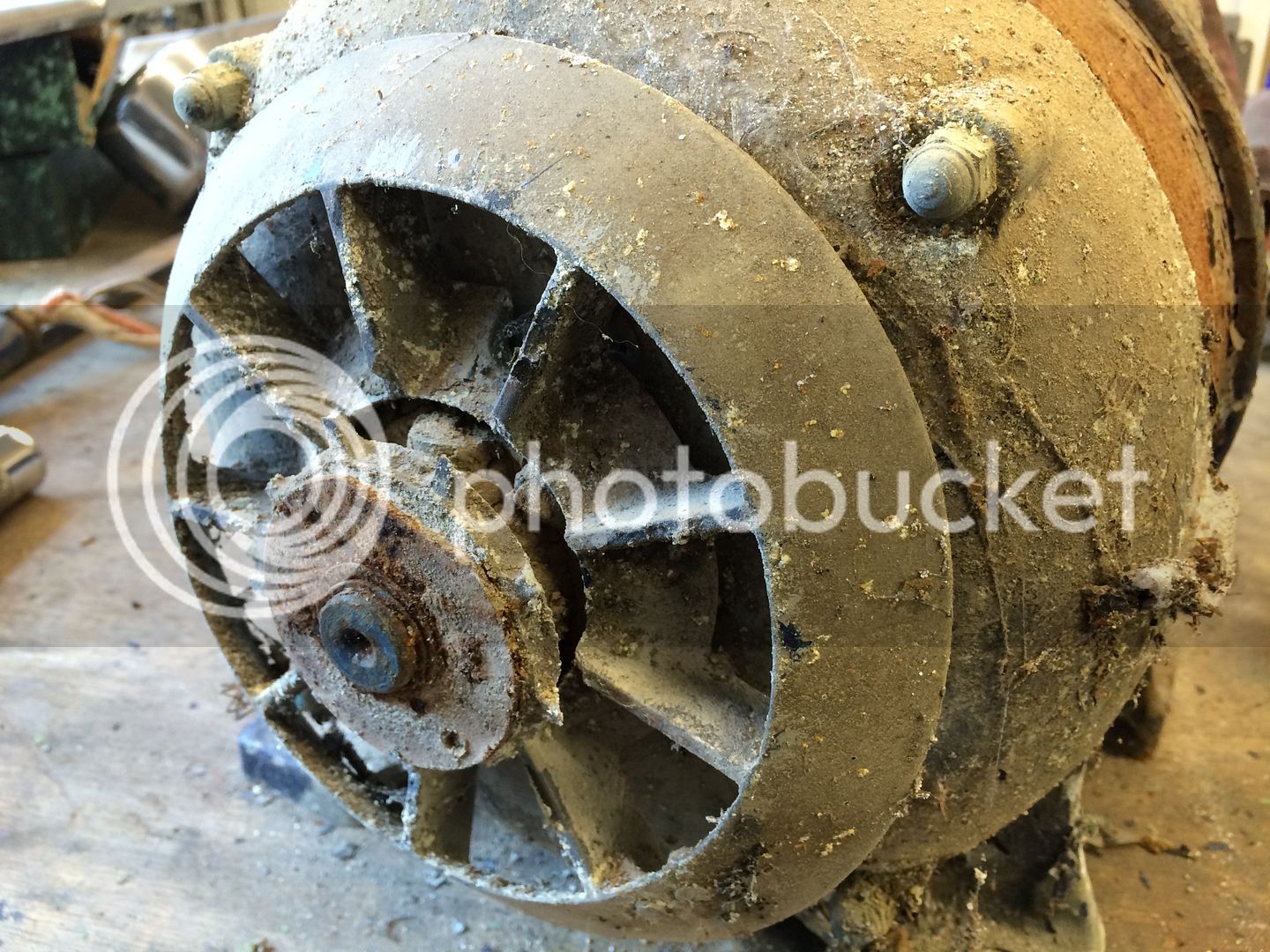

damaged fan

- Thread starter wallace

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Looking at the white powder it could be cast Ali of some kind, I would think a good welder would be able to sort it out. Might not be pretty but doable depending on the material with some preheating etc.

Mark

Mark

wallace

Established Member

Thanks mark, your right its cast ali. I think my mig can take aluminium wire I wonder if this will work

I would think you'll struggle to weld it with a MIG - Ally is a pig at the best of times to weld, let alone such a complex shape. I think you need a different gas as well? I'd see if you can find a good local welder for it and get it TIG'd up.

t8hants

Established Member

I think I would prefer to get that TIG'd, if it was doable and if it were mine.

wallace

Established Member

I think your right. Another thing that might be an issue is it being off balance after being welded

I think Tig would be alot more reliable, you could get it done and then run the motor and see how much it wobbles.

You might get lucky and not get any vibration, if it does vibrate you could try adding some weights until it goes away. The stick on car wheel weights would work well. I have balanced forestry machines by welding weights onto components, a bit of trial and error but it works.

Mark

You might get lucky and not get any vibration, if it does vibrate you could try adding some weights until it goes away. The stick on car wheel weights would work well. I have balanced forestry machines by welding weights onto components, a bit of trial and error but it works.

Mark

novocaine

Established Member

easier to remove material for balancing than to add it, much like you'd do with an armature. you can static balance it first before fitting to get a better balance and not destroy the motor, set it between 2 points on an arbor is the easiest approach much like balancing a prop for an RC plane, plenty of videos on doing that.

novocaine":vw0hast7 said:easier to remove material for balancing than to add it, much like you'd do with an armature. you can static balance it first before fitting to get a better balance and not destroy the motor, set it between 2 points on an arbor is the easiest approach much like balancing a prop for an RC plane, plenty of videos on doing that.

I'm reminded of a story my Grandfather told me..... He spent the final months of the Second World War as a Wireless Op in RAF Transport Command. On one particular trip, they were flying a Short Stirling across India when they were struck by a large bird. Upon landing they found that the bird hit the front of one of the engines and snapped two blades off the cooling fan. Being stuck in some far-flung corner of the Empire, they were faced with a wait of several weeks while a new engine was shipped out. Then my Grandfather came up with the idea of cutting off the opposite two fan blades to balance the engine. They were back on their way much sooner than expected :lol:

There was a guy in America who did something similar with a jet engine he bought at a scrap yard. Removing opposite blades worked fine apparently. He was using the engine in a land speed record attempt of some sort until the military found out he was using one of their old engines. The engine should have been scrapped but they did allow him to use it for a while in his vehicle.

As for the OP's motor, that should be scrapped as well. Just buy a new one!

As for the OP's motor, that should be scrapped as well. Just buy a new one!

isn't Crappite the technical name for the alloy of which that fan is made?

No skills

Established Member

sunnybob":1us9dvck said:no, thats what makes superman fallible.

It's not a metal that does that, Henry Cavill is the culprit.