mickthetree

Established Member

Hi all

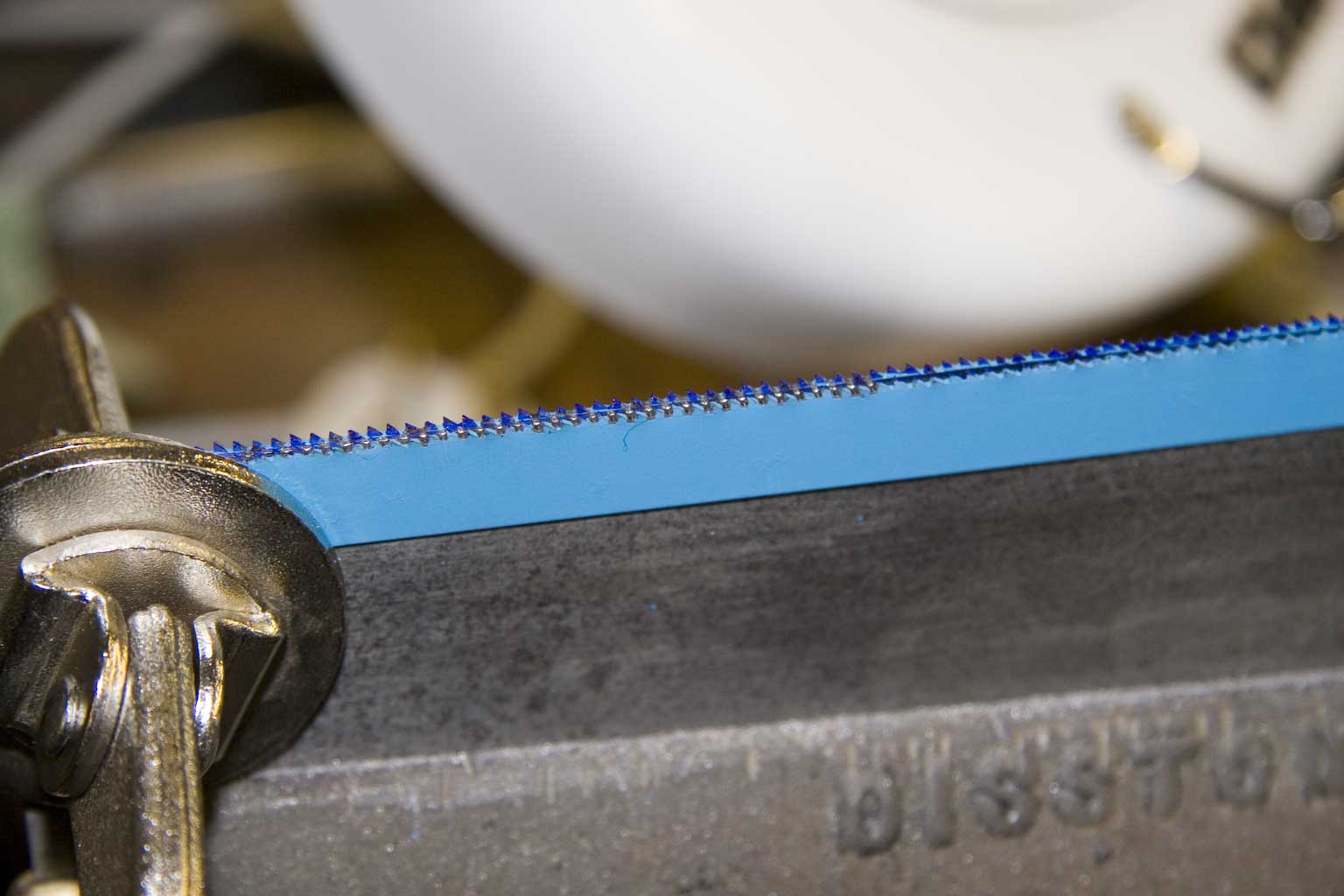

I have just acquired a box full of old tools. Some panel saws, some chisels, lots of old files and a tenon saw.

The saw has a bow in it around the centre of the blade and the handle needs reattaching.

The blade also has an arc upwards in the centre if looking from the side and the teeth are all different heights.

I thought I might use it to learn how to sharpen a saw before I buy a good one, but I guess I will need to take out the convex first by flattening. This will leave it needing new teeth cut.

I have seen a raft of sites on sharpening, all the jigs, marking guides etc, but no one seems to mention cutting new teeth from scratch other than giving it to a saw doctor. I don't think this saw is worth paying someone to do that on as it has the bow in the blade, so how can I cut new teeth myself?

Do I just use the files I have been given? or will that knacker them out? (if they are still any good in the first place)

Any suggestions greatly appreciated.

Paul

I have just acquired a box full of old tools. Some panel saws, some chisels, lots of old files and a tenon saw.

The saw has a bow in it around the centre of the blade and the handle needs reattaching.

The blade also has an arc upwards in the centre if looking from the side and the teeth are all different heights.

I thought I might use it to learn how to sharpen a saw before I buy a good one, but I guess I will need to take out the convex first by flattening. This will leave it needing new teeth cut.

I have seen a raft of sites on sharpening, all the jigs, marking guides etc, but no one seems to mention cutting new teeth from scratch other than giving it to a saw doctor. I don't think this saw is worth paying someone to do that on as it has the bow in the blade, so how can I cut new teeth myself?

Do I just use the files I have been given? or will that knacker them out? (if they are still any good in the first place)

Any suggestions greatly appreciated.

Paul