TimothyClaypole

Established Member

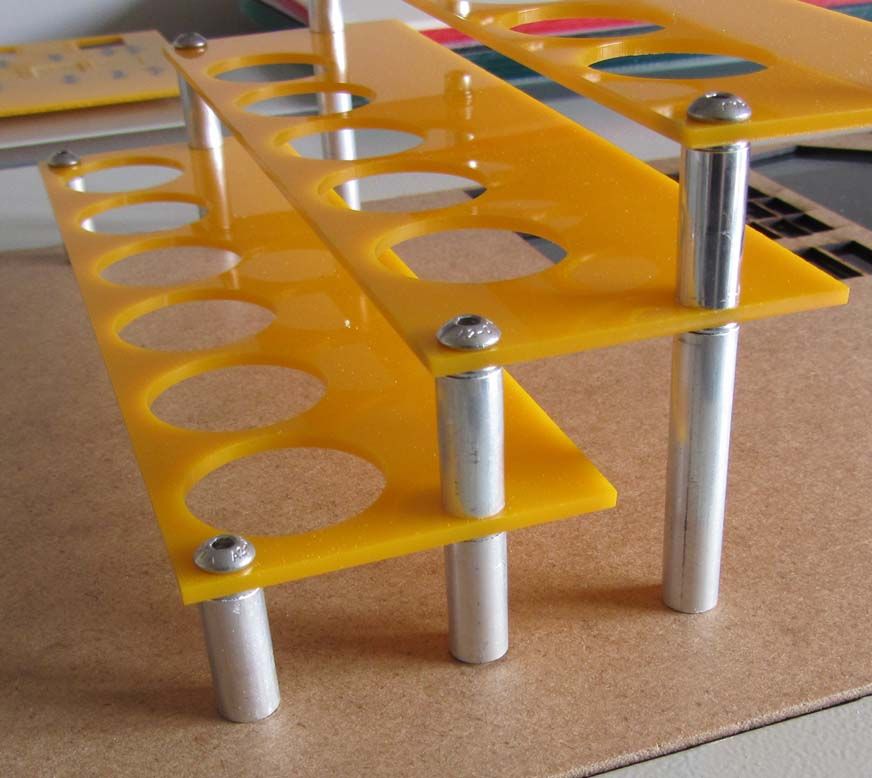

I'm working on something that i'm using 10mm aluminium tubing, 2mm wall and some threaded bar at 5mm.

I've assorted tools but could do with something to cut these two that's not massively noisy as I've no outside work place at the minute, probably not something that goes together cutting metal quietly.

I've a Dremel, Proxxon hobby plastic boxed saw table, a Clarke 10" saw table, 6 and 9" grinders, reciprocating saw, jigsaw, circular saw etc. but they are all a bit noisy for indoor use apart from the Proxxon which is

hopelessly underpowered.

I've been cutting them by hand with a junior hacksaw but each item needs around 18 bits of tubing and 8 pieces of bar...

Or just build a shed? :mrgreen:

I've assorted tools but could do with something to cut these two that's not massively noisy as I've no outside work place at the minute, probably not something that goes together cutting metal quietly.

I've a Dremel, Proxxon hobby plastic boxed saw table, a Clarke 10" saw table, 6 and 9" grinders, reciprocating saw, jigsaw, circular saw etc. but they are all a bit noisy for indoor use apart from the Proxxon which is

hopelessly underpowered.

I've been cutting them by hand with a junior hacksaw but each item needs around 18 bits of tubing and 8 pieces of bar...

Or just build a shed? :mrgreen: