Hi Chaps and chapesses,

My first post in the turning fraternity although I have lurked and admired here for a while.

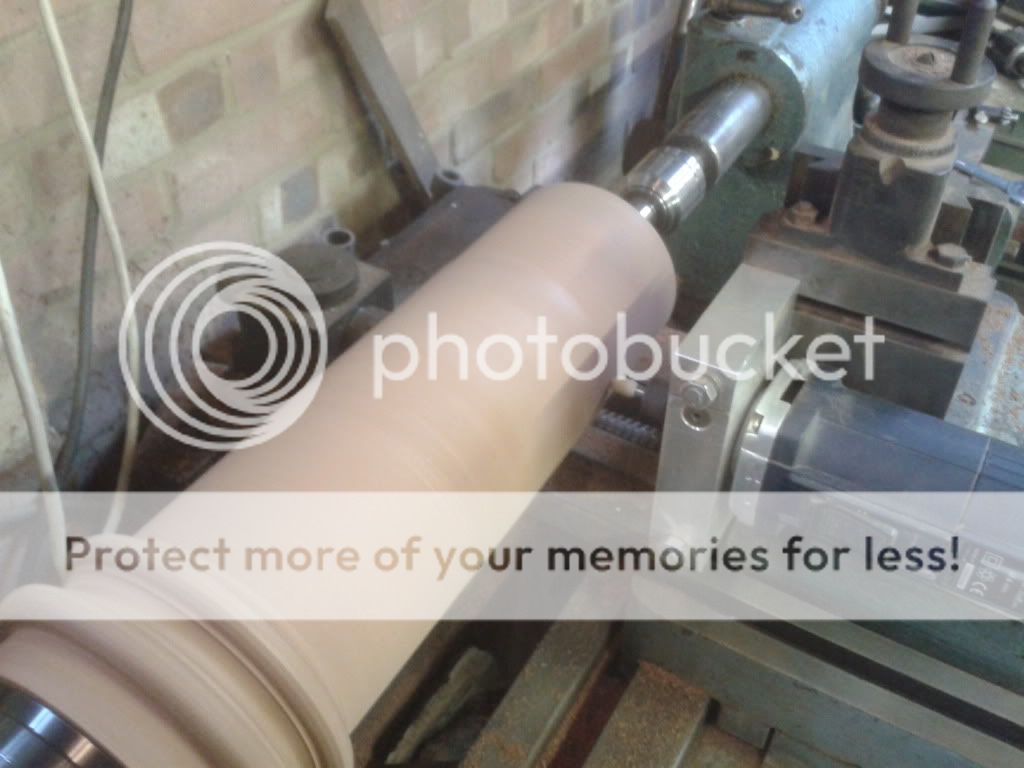

Long story short. Father bought an early Colchester Student metalworking lathe when he retired and its been in his barn for the last ten or so years working perfectly well on his inverter (3 phase working on 240v a/c).

I see from a search of Users' lathes that no-one on here uses a Colchester for woodturning.

Now, parents are downsizing and moving. Therefore Colchester available. I and SWMBO also moving shortly. Yet to go on the market. Complicated but not needed here.

Question. Should I buy dad's lathe (and store it somewhere) or let it go and buy a dedicated woodworking lathe when I know what space Ive got in our new space?

Sorry if its a silly query. I want to be able to turn spindles, bowls, other decorative stuff,

Cheers

Andrew

My first post in the turning fraternity although I have lurked and admired here for a while.

Long story short. Father bought an early Colchester Student metalworking lathe when he retired and its been in his barn for the last ten or so years working perfectly well on his inverter (3 phase working on 240v a/c).

I see from a search of Users' lathes that no-one on here uses a Colchester for woodturning.

Now, parents are downsizing and moving. Therefore Colchester available. I and SWMBO also moving shortly. Yet to go on the market. Complicated but not needed here.

Question. Should I buy dad's lathe (and store it somewhere) or let it go and buy a dedicated woodworking lathe when I know what space Ive got in our new space?

Sorry if its a silly query. I want to be able to turn spindles, bowls, other decorative stuff,

Cheers

Andrew