I know this is not strictly woodworking (it will have a wooden base!  ) but a few other members said I should post it.

) but a few other members said I should post it.

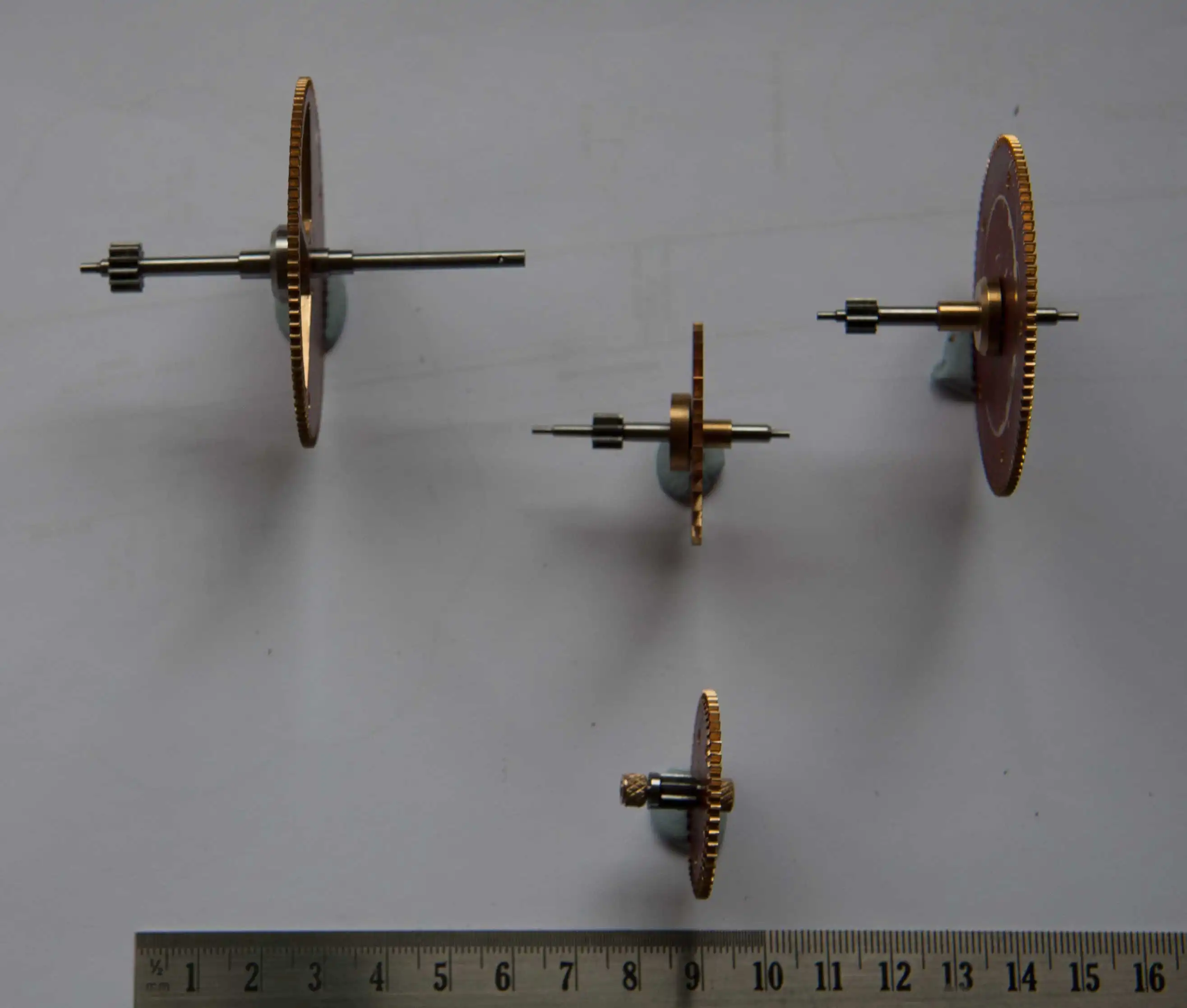

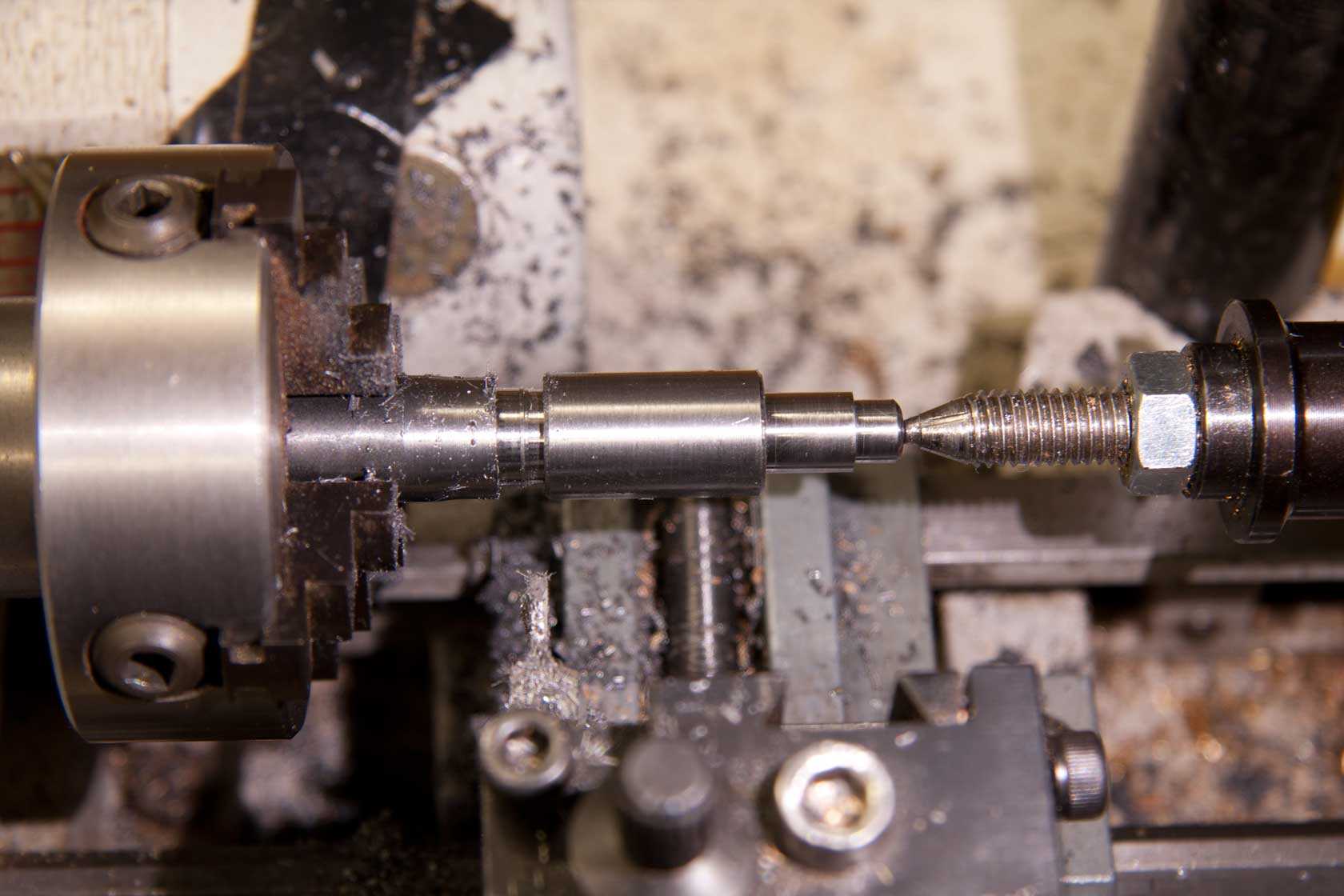

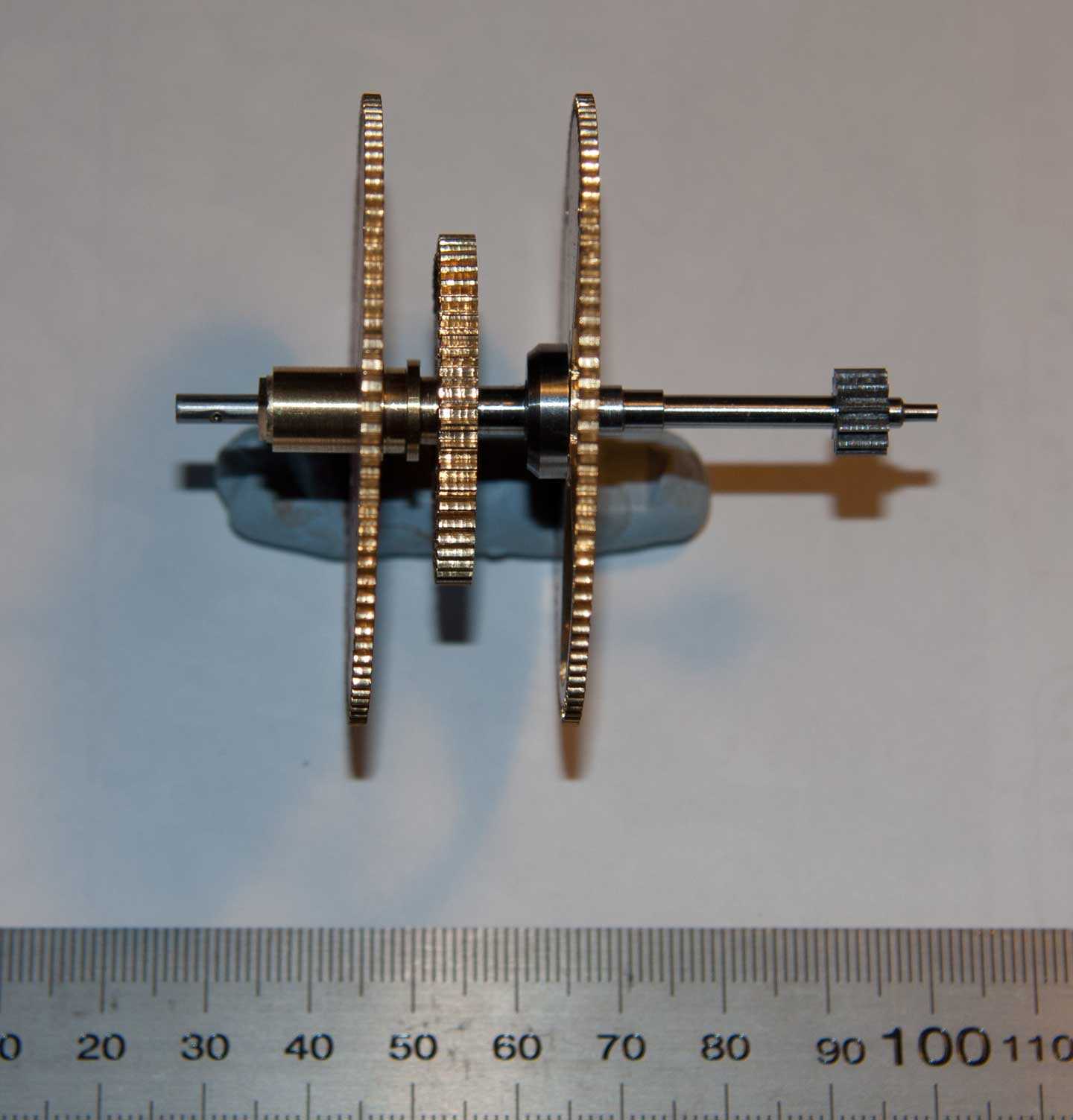

It is a Beginners Clock I am making (on "rainy days") using my tiny S/H Unimat 3 Lathe - it came with a set of clock wheel cutters, so it seemed a shame not to put them to use? All cut from brass sheet.

Wheels still to be cut out for spokes, filed, burnished, polished etc - the red is red oxide paint to allow the marking out.

Rod

It is a Beginners Clock I am making (on "rainy days") using my tiny S/H Unimat 3 Lathe - it came with a set of clock wheel cutters, so it seemed a shame not to put them to use? All cut from brass sheet.

Wheels still to be cut out for spokes, filed, burnished, polished etc - the red is red oxide paint to allow the marking out.

Rod