Got a good few hours done friday night and saturday before lunch

First I assembled and glued up the little secret drawer as follows:

Then I glued up the back onto the side as the secret drawer cannot be finished without the inside being absolutely smooth. The diagonal clamp is only there to keep the agnle exactly to 90 degrees

I finished the rest of the cabinet where the main drawer was to go - just a simple pair of rails that the drawer will slide on. The brass screws in the back piece are necessary as I may have to access the secret drawer if I have problems with it

The drawer is very straightforward - dovetails for the front and a simple rebate joint for the back

The base of this drawer is also the iroko which I am required to use in the construction.

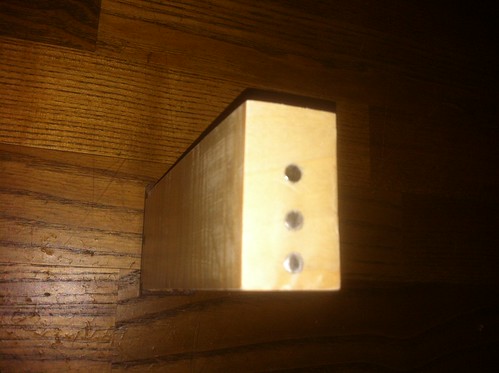

For the secret drawer mechanism, I embedded 3 x 6mm diameter magnets in the drawer like this using a short 6mm lip and spur bit with a depth stop

From top to bottom they go N S N. The sliding bar in the cabinet also has 3 magnets in it - also N S N from the top - but at rest the position is such that the top 2 of the sliding bar magnets engage the bottom 2 of the drawer magnets - is N attracts S and S attracts N so the drawer is held in by these 2 magnet pairs. Here is the inside of the secret drawer cabinet showing these 2 magnets visible and the little spring

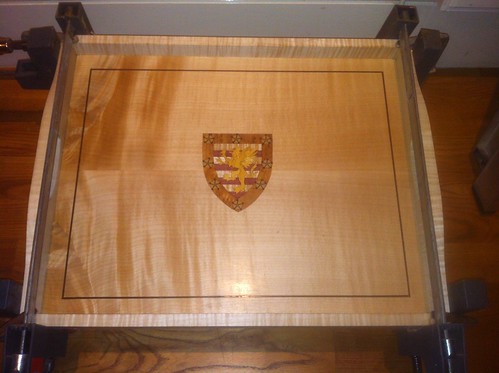

So, in its resting state, the corner of the table looks like this

Upon pressing this button

The drawer pops out quite smartly to about 3 inches

I have to be honest I never thought it would work as well as this and am delighted with the result. Maybe I will work out how to upload a short video?

Thanks for looking

Mark