mailee

Established Member

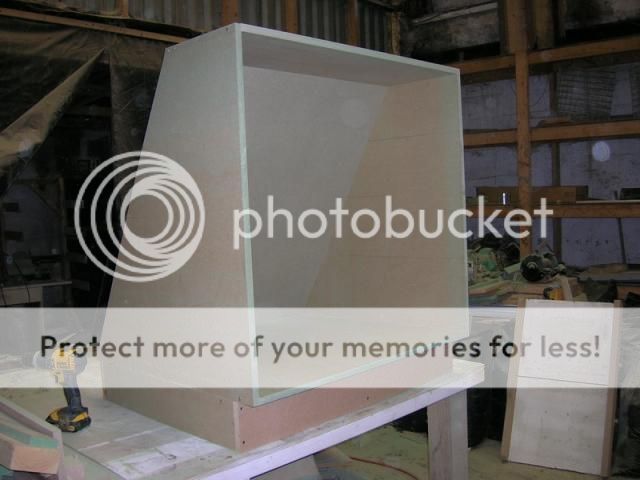

On Friday I made a start on a set of built in drawers for an attic room. Again these are all in MRMDF and will be painted. Spent most of Friday cutting out the pieces, rebating and cutting biscuit slots.

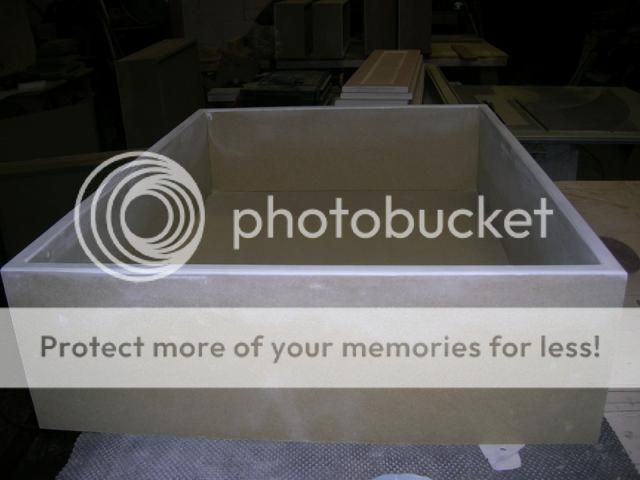

I also got all of the drawer boxes cut out and slots cut for the bases.

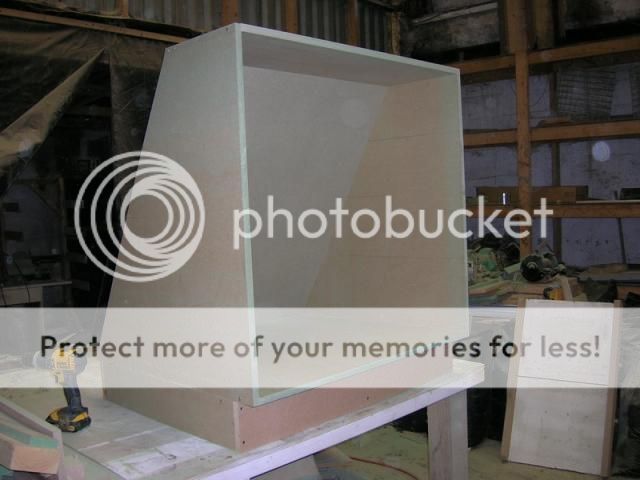

Next I made the plinth up which was quick and easy as it won't be seen once in place.

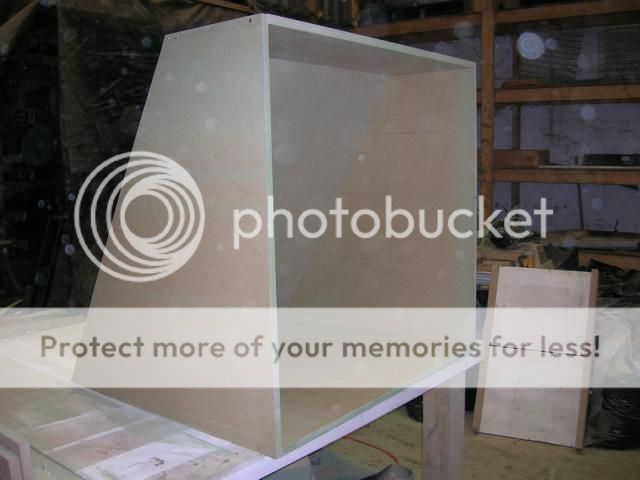

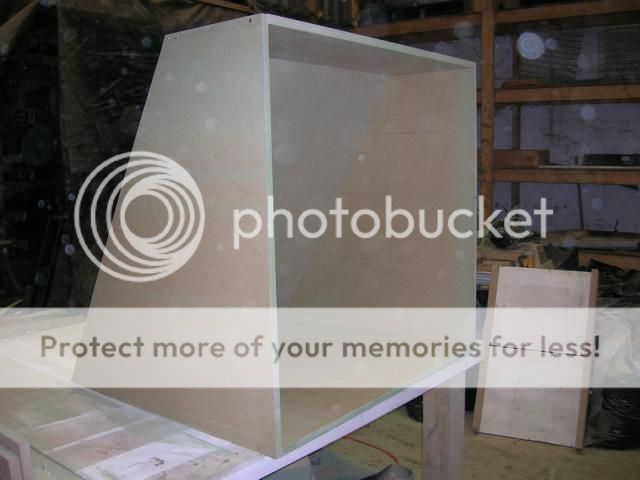

That saw me at the end of the day on Friday and being behind with my jobs I decided to work Saturday for this one. Nice early start on Saturday and I had a dry fit of the unit and fitted the back in place to trim it.

Both of these units will need to be assembled on site due to the narrow staircase up to the attic. I then added the plinth.

I also eventually got some of the drawer boxes in the clamps.

I say eventually as when I started to use the domino for the joints I got through two full drawer boxes before I realised I had put the slot in the wrong surface! So much for trying to catch up. :roll:

So much for trying to catch up. :roll:

I also got all of the drawer boxes cut out and slots cut for the bases.

Next I made the plinth up which was quick and easy as it won't be seen once in place.

That saw me at the end of the day on Friday and being behind with my jobs I decided to work Saturday for this one. Nice early start on Saturday and I had a dry fit of the unit and fitted the back in place to trim it.

Both of these units will need to be assembled on site due to the narrow staircase up to the attic. I then added the plinth.

I also eventually got some of the drawer boxes in the clamps.

I say eventually as when I started to use the domino for the joints I got through two full drawer boxes before I realised I had put the slot in the wrong surface!