Hi

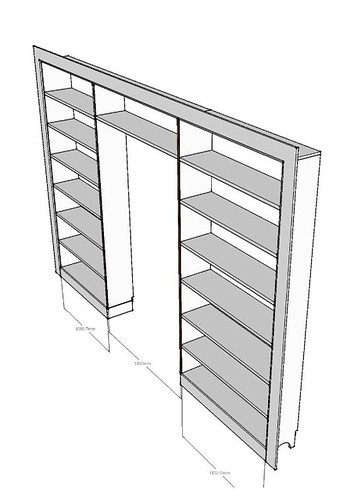

I am wanting to make a built in bookcase on the backwall of our living room. It will be surrounding french doors.

I am wanting to make it out of 8 x 4 sheets of oak veneered Mdf. 18mm for the carcass and 26mm for the shelves which will span 1.1 - 1.3 m.

I have drawn a plan and will upload it soon. I have chosen to edge the veneered mdf with kiln dried oak or some similar hardwood cut at 18/26mm and 5mm thick.

My only concern is sagging over time. This is why I chose 26mm MDF for the shelves. I was thinkining of installing a support under each shelf front making the shelves look much thicker but adding rigidity.

I would love to hear any ideas.

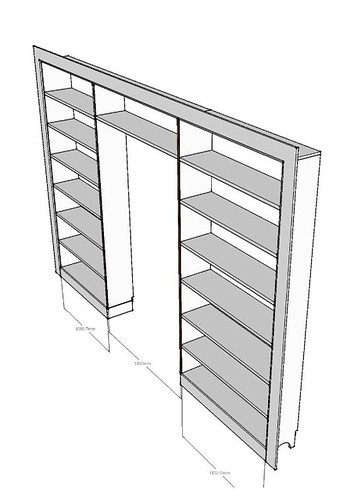

I am wanting to make a built in bookcase on the backwall of our living room. It will be surrounding french doors.

I am wanting to make it out of 8 x 4 sheets of oak veneered Mdf. 18mm for the carcass and 26mm for the shelves which will span 1.1 - 1.3 m.

I have drawn a plan and will upload it soon. I have chosen to edge the veneered mdf with kiln dried oak or some similar hardwood cut at 18/26mm and 5mm thick.

My only concern is sagging over time. This is why I chose 26mm MDF for the shelves. I was thinkining of installing a support under each shelf front making the shelves look much thicker but adding rigidity.

I would love to hear any ideas.