CHJ

Established Member

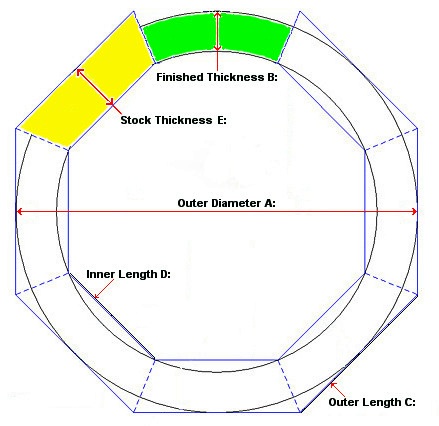

Prompted by a Thread question by woodfarmer regarding cutting segments for bowls I jumped in with some images.

I've taken the liberty of cribbing some of the material from that thread to start this W.I.P. off.

Now like all workshop projects there are no hard and fast rules of "how to do" and the following is just a rough run through of how I set about my simple segmented boxes and bowls, others will use different cutting and turning methods, indeed far more accurate and intricate segment preparation and turning skills than I will ever attempt or have the patience to master.

Hopefully the following will prompt someone new to turning to have a go, if nothing else it saves a great deal of expense on wood stock and reduces the waste wood creation considerably.

For my stuff I use a basic Chop Saw, just need to make sure everything is set up square in the vertical plane and that angles are set accurately in the horizontal.

The most important of needs is to prepare your stock for even thickness & square so that it can be cut accurately by just flipping 180deg.

I've taken the liberty of cribbing some of the material from that thread to start this W.I.P. off.

Now like all workshop projects there are no hard and fast rules of "how to do" and the following is just a rough run through of how I set about my simple segmented boxes and bowls, others will use different cutting and turning methods, indeed far more accurate and intricate segment preparation and turning skills than I will ever attempt or have the patience to master.

Hopefully the following will prompt someone new to turning to have a go, if nothing else it saves a great deal of expense on wood stock and reduces the waste wood creation considerably.

For my stuff I use a basic Chop Saw, just need to make sure everything is set up square in the vertical plane and that angles are set accurately in the horizontal.

The most important of needs is to prepare your stock for even thickness & square so that it can be cut accurately by just flipping 180deg.

<<<< Link

<<<< Link