transatlantic

Boom!

I was recently watching one of Matt Estleas videos (he's very good). In particular this one on how to cut a half lap :

https://www.youtube.com/watch?v=dfXmFErs9J0

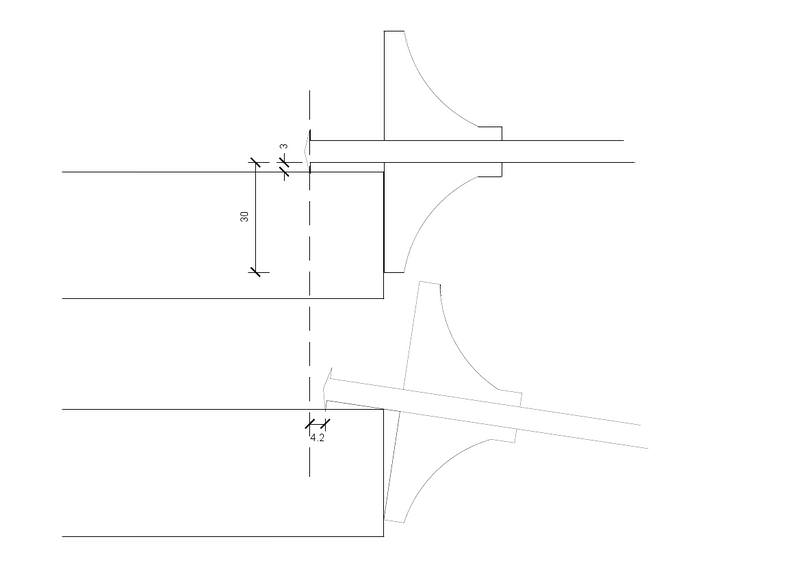

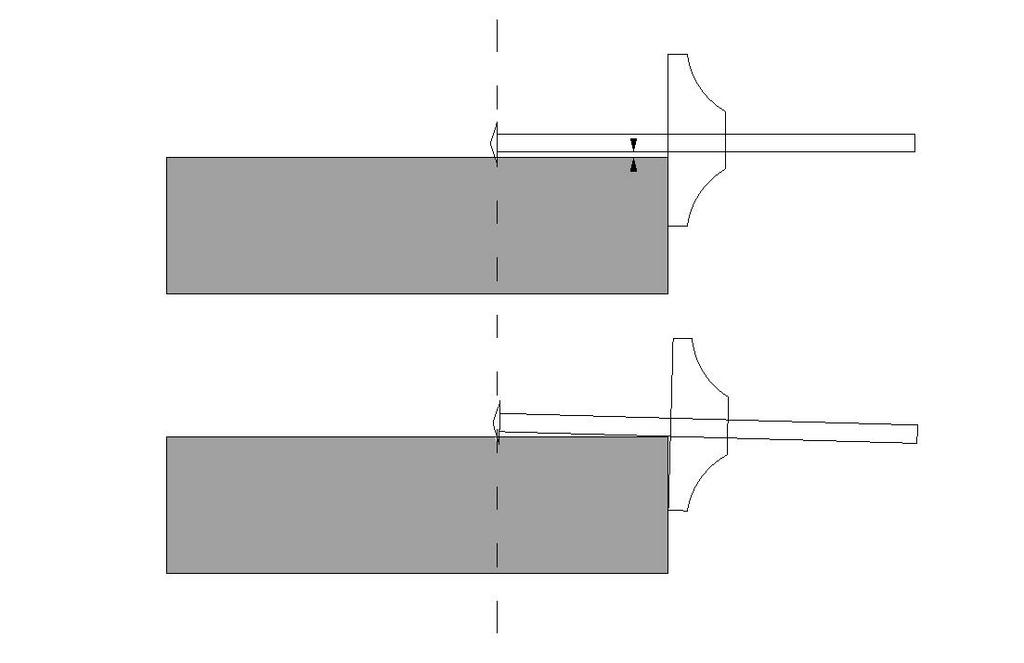

In it, he talks about how important it is to use the marking gauge off the same reference face on both your pieces. This makes complete sense as then you don't have to get the half lap exactly central as any error is accounted for.

But when using this approach, due to the beveled edge of the marking gauge blade, you'll get a clean cut on one piece, but on the other, you'll get the dent of the bevel? Am I missing something?

https://www.youtube.com/watch?v=dfXmFErs9J0

In it, he talks about how important it is to use the marking gauge off the same reference face on both your pieces. This makes complete sense as then you don't have to get the half lap exactly central as any error is accounted for.

But when using this approach, due to the beveled edge of the marking gauge blade, you'll get a clean cut on one piece, but on the other, you'll get the dent of the bevel? Am I missing something?