Rhyolith

Established Member

Well, I think its more or less finished! It only took half a year.

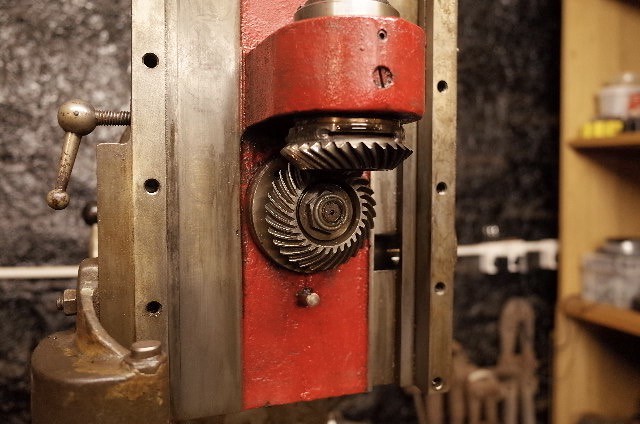

Bradford Milling Machine by Rhyolith, on Flickr

Bradford Milling Machine by Rhyolith, on Flickr

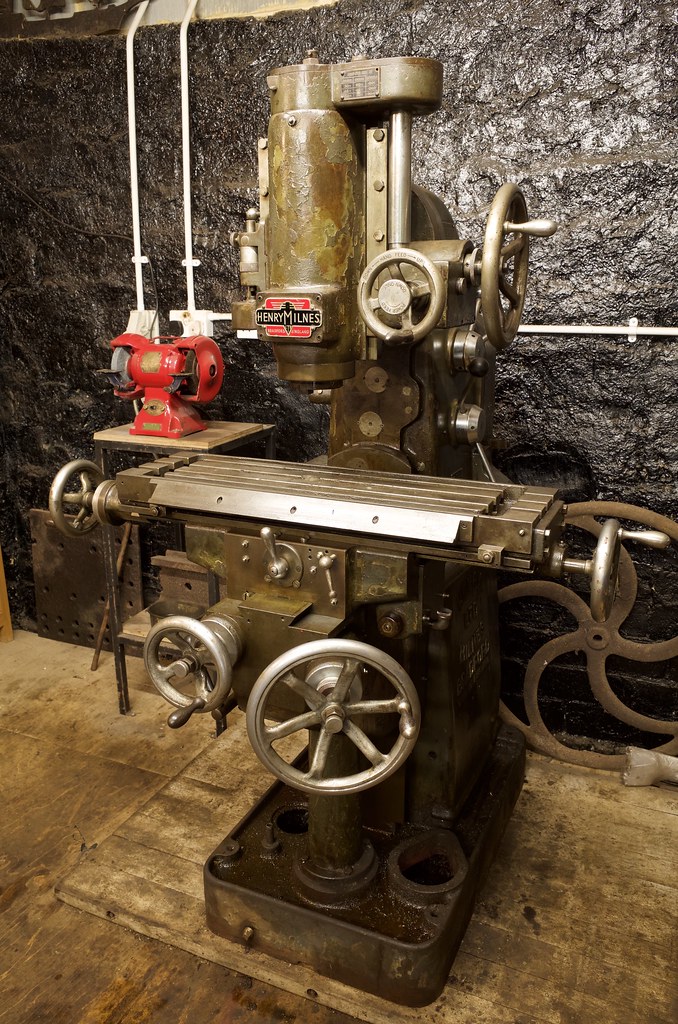

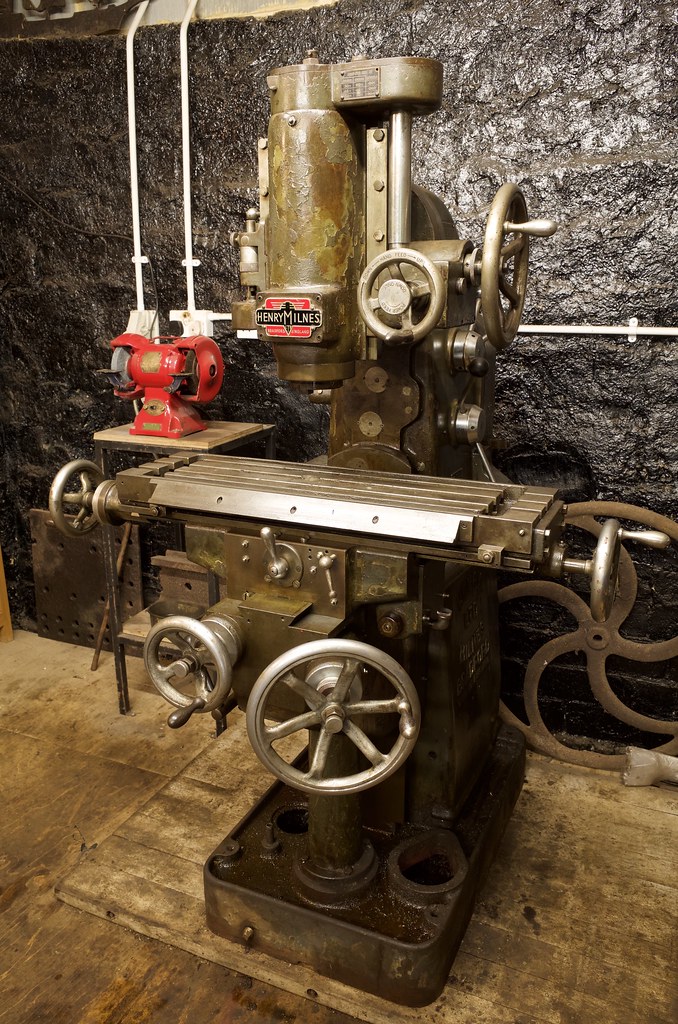

Henry Milne Mill by Rhyolith, on Flickr

Henry Milne Mill by Rhyolith, on Flickr

Just need to work out the last few bits of lubrication. Such as where those oil feeders on the back go and what to lube the roller bearing with (NUTO 32 seems to thin, just pores out the bottom after a while).

Also gotta confirm what fitting this is. Took some measurements now so hopefully that means someone can tell me for sure:

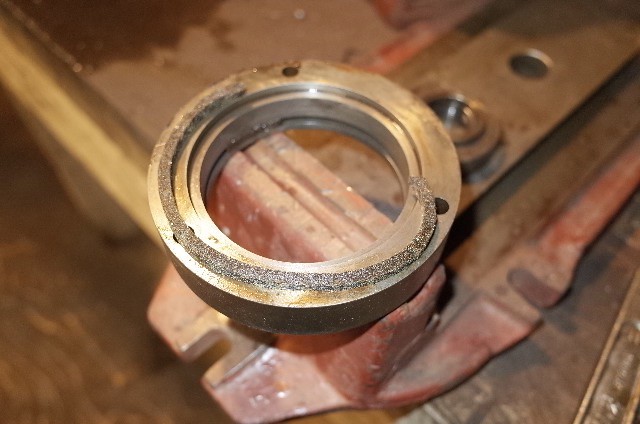

R0000004 by Rhyolith, on Flickr

R0000004 by Rhyolith, on Flickr

top (above taper) is 1" or 25.5mm in diameter and 17mm high

the indent at the top of the taper is 28.5mm in diameter and 7mm high

bottom of the taper is 44mm

the taper is 70mm long

I would like to get a collet attachment to fit the above for smaller bits, but the ones on Axminster seem very expensive. Anywhere else i should look? (will look on eBay regardless).

Bradford Milling Machine by Rhyolith, on Flickr

Bradford Milling Machine by Rhyolith, on Flickr Henry Milne Mill by Rhyolith, on Flickr

Henry Milne Mill by Rhyolith, on FlickrJust need to work out the last few bits of lubrication. Such as where those oil feeders on the back go and what to lube the roller bearing with (NUTO 32 seems to thin, just pores out the bottom after a while).

Also gotta confirm what fitting this is. Took some measurements now so hopefully that means someone can tell me for sure:

R0000004 by Rhyolith, on Flickr

R0000004 by Rhyolith, on Flickrtop (above taper) is 1" or 25.5mm in diameter and 17mm high

the indent at the top of the taper is 28.5mm in diameter and 7mm high

bottom of the taper is 44mm

the taper is 70mm long

I would like to get a collet attachment to fit the above for smaller bits, but the ones on Axminster seem very expensive. Anywhere else i should look? (will look on eBay regardless).