Charlie Woody":2hpuahwk said:

Thanks to everyone for their helpful responses. I am learning a lot from these helpful posts. I have some questions for petermillard, particularly, however some of the questions are more general and hopefully everybody will chip in.

Hi there - that's quite a list, I'll do my best...

I am trying to understand how your “carcass cutlist spreadsheet” works.

It shows dimensions for flush door but rail and stiles shown below – why is that?

Some carcasses have panel doors, some have flush doors - it's a multi-functional spreadsheet

you'll notice that there isn't a quantity listed for the flush door...

Under “door calc” groove 20mm is shown – what is this for as I thought the door panels were 6mm?

That's for groove depth - used to calc the panel size from the rails and stiles...

I don’t understand why you have 2 stiles, 2 rails and 2 rails & stiles.

OK, initial rails and stiles (separate entries) are to size, subsequent one ("rails & stiles") are the number of lengths of material (2440 x 100 in this example) I'll need to produce the doors - as guided by the ' rails and stiles per door' calc at the bottom...

Looking at the drawing the door seems to have 2 stiles & 3 rails (top, middle & bottom). Could you explain please?

This worksheet wasn't set up to allow for a third rail at the time, so I treated it as a 2-rail door and added a third in 'manually' afterwards.

What are the formulae you have used for these calculations, so I can have a go at making my own in excel please?

Not being funny, but better for you to work this out for yourself - mine has all kinds of 'idiosyncrasies' that make sense to me, but possibly not to anyone else! Happy to help with the basic formulae if you need it though - would probably do this as a separate reply as it would be better with examples..

When you say “rationalised” for the timber yard do you use something like MaxCut to produce the most efficient sheet cutting?

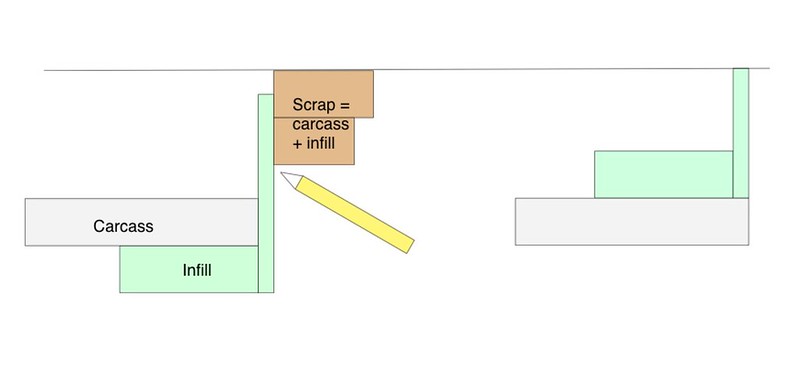

No - I leave that to the yard; the guy on the panel saw is way more efficient than any software! By rationalise, I mean tidy up e.g. the single and double wardrobes I refer to in that thread are the same height and depth, so the carcass sides are common, but using this cultist spreadsheet, they show up as "2# 580 x 1950" twice - once or each carcass. I 'rationalise' this to a single entry of "4# 580 x 1950". Make sense? I also take out any references to phantom flush doors etc...

I don’t have a Domino but do have a biscuit jointer – will this work just as well?

I imagine they'll be fine, though I've never used biscuits on carcass construction personally - perhaps someone else will know more?

If finish is applied to the various components before final assembly how do you stop it getting into the Domino (Biscuit) slots? Also if finish is on the edges to be glued won’t this reduce the glue “grab”?

I haven't found this to be a particular problem, but the vast majority of my work is painted; again, perhaps someone else can chime in on this one?

You say you use angle plates screwed to the back of the wardrobes to fix them to the wall – how do you get at them to do this? If the angle plate is fixed to the wardrobe first and then placed in position with only a small clearance all around a unit I can’t see how you could get your hand between the wall and the carcass to fix to the wall.

Sorry, poorly worded. I either use angle plates or repair plates. Angle plates are set into the top of the carcass, so remain accessible, and repair plates are sets to the back of the carcass, with just a single hole showing above the carcass top.,

How would you change your techniques to work with veneered MDF – filling holes where you screwed the carcase bottom to plinth, using a solid timber face frame rails & stiles etc?

I think I'd either use hardwood plugs to cover the screw-holes, or just use tongue-tite screws - they have a very small head, so can be easily 'lost' with a bit of e.g. wax stick.

The photo you show of the scribing shows a clamp, but I don’t see where you have clamped it to the carcass? Where I will be working is a Victorian house which has large skirting and coving – how would you work around these? Bradnaylor's photos show him offering the glued up face frame to one side of an alcove first, then the other - but how would you do it if the face frame had to fit within a deep alcove?

The clamp was used as a spreader, and bears against the carcass base - or perhaps the shelf, can't remember tbh. With large/ornate skirts and cove, I usually start with a 'profile gauge' - I bought mine from a tile shop yonks ago - then make card templates until I get it right. Then the usual coping saw/jigsaw/whatever...

How do you lay out and drill for the hinges – for flush and inset doors?

I use a 99p hinge marker from eBay - does the job.

Interesting you used hinges with built in soft closers. What model number are they – there seem to be some many variations? Last year I used some with clip on soft closers and they are a pain as they keep dropping off!!

I get them from my timber yard - I'll have to check for a number when I'm back n the workshop.

All the software you use is for smart phones / tablets neither of which I possess. Are there similar products for the old fashioned PC?

My workflow is almost all phone/tablet based now, but I'm sure there'll be something similar for the PC - perhaps a PC user can chip in here?

I have being trying to get my head around Sketchup but am still having problems with it – see attached a partially finished drawing. Is there something else that is easier to use and also free? Do I really need 3D or will 2D be ok.

I gave up using sketch up a few years back - I found I was spending longer doing the drawings than I was making the stuff. I only use/supply 2-D drawings now; haven't noticed a dramatic drop-off in customers...

WRT your other Qs - I don't have a great deal of experience with face-frames tbh, so if you don't mind I'll let someone else pitch in here.

Hope this has helped - if not, do ask and I'll try to clarify.

Cheers, Pete.