bugbear

Established Member

Paul Chapman":2xbamdro said:bugbear":2xbamdro said:The only planes I've ever seen in the UK with toothing blades are toothing planes (!).

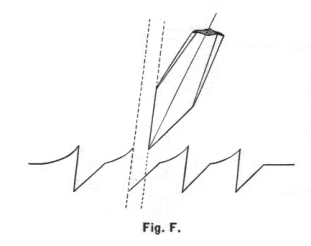

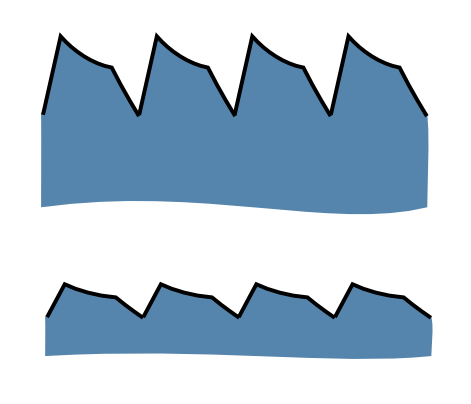

There seem to be two different and quite distinct uses for toothed blades. The common one (as far as I can ascertain from the research I've done) is in preparing groundwork for veneering. I've also seen references to their use by, for example, makers of musical instruments where they are working in thin, exotic timbers subject to tear-out.

What we saw at West Dean was their use in stock preparation, where you would use the blade in situations where a scrub-type or heavily cambered blade would normally be used - and the big advantage of the toothed blade is the lack of tear-out.

I had certainly not seen them used for this purpose in the past and haven't seen any references to this type of use in published material. Maybe that's why there seems to be a scarcity of bevel-down toothed blades - they simply weren't commonly used in the past for stock removal work.

Cheers :wink:

Paul

Agreed - stock prep with toothed blades seems to be that rarest of things - a genuinely new woodworking trick.

BugBear