Berncarpenter

Established Member

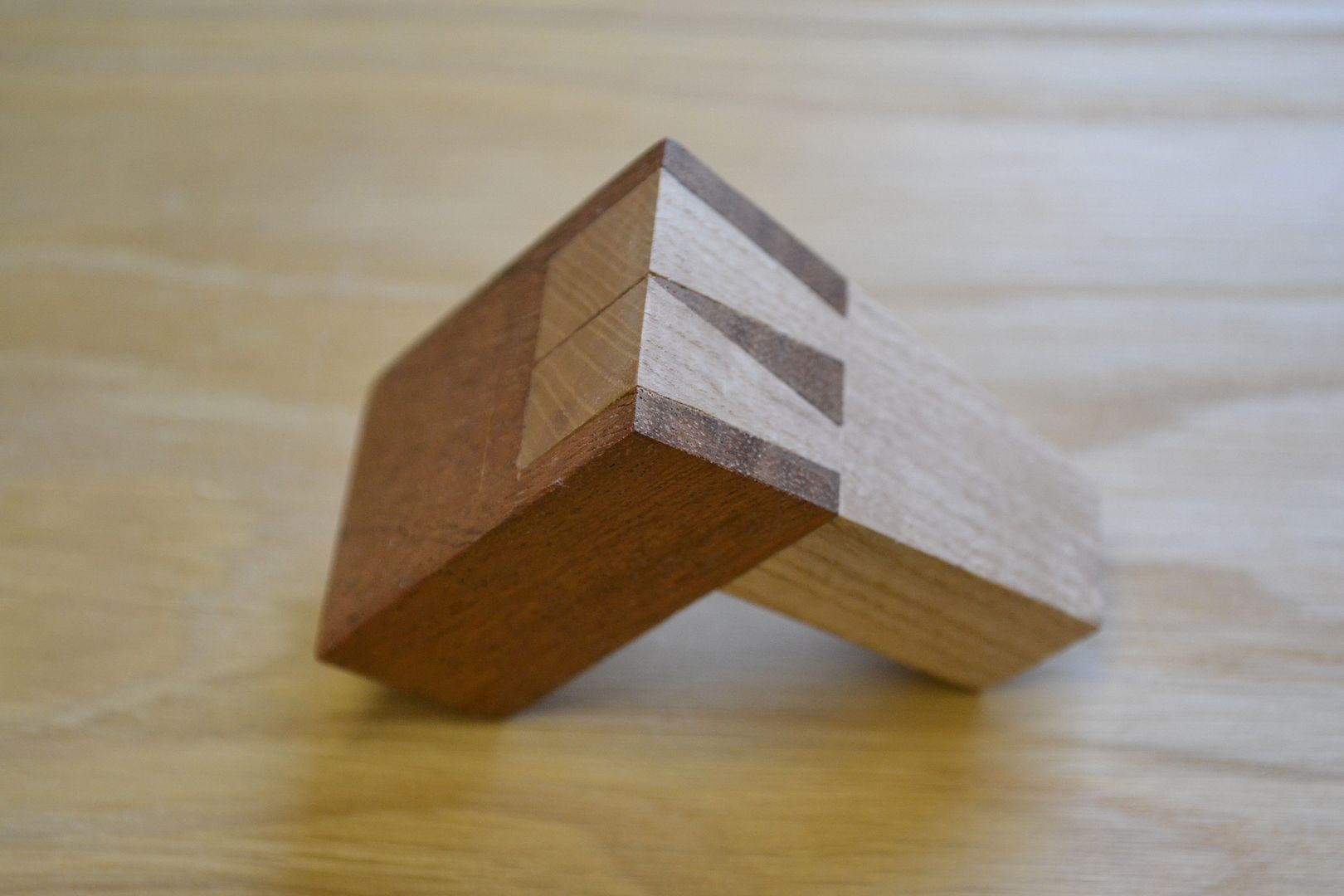

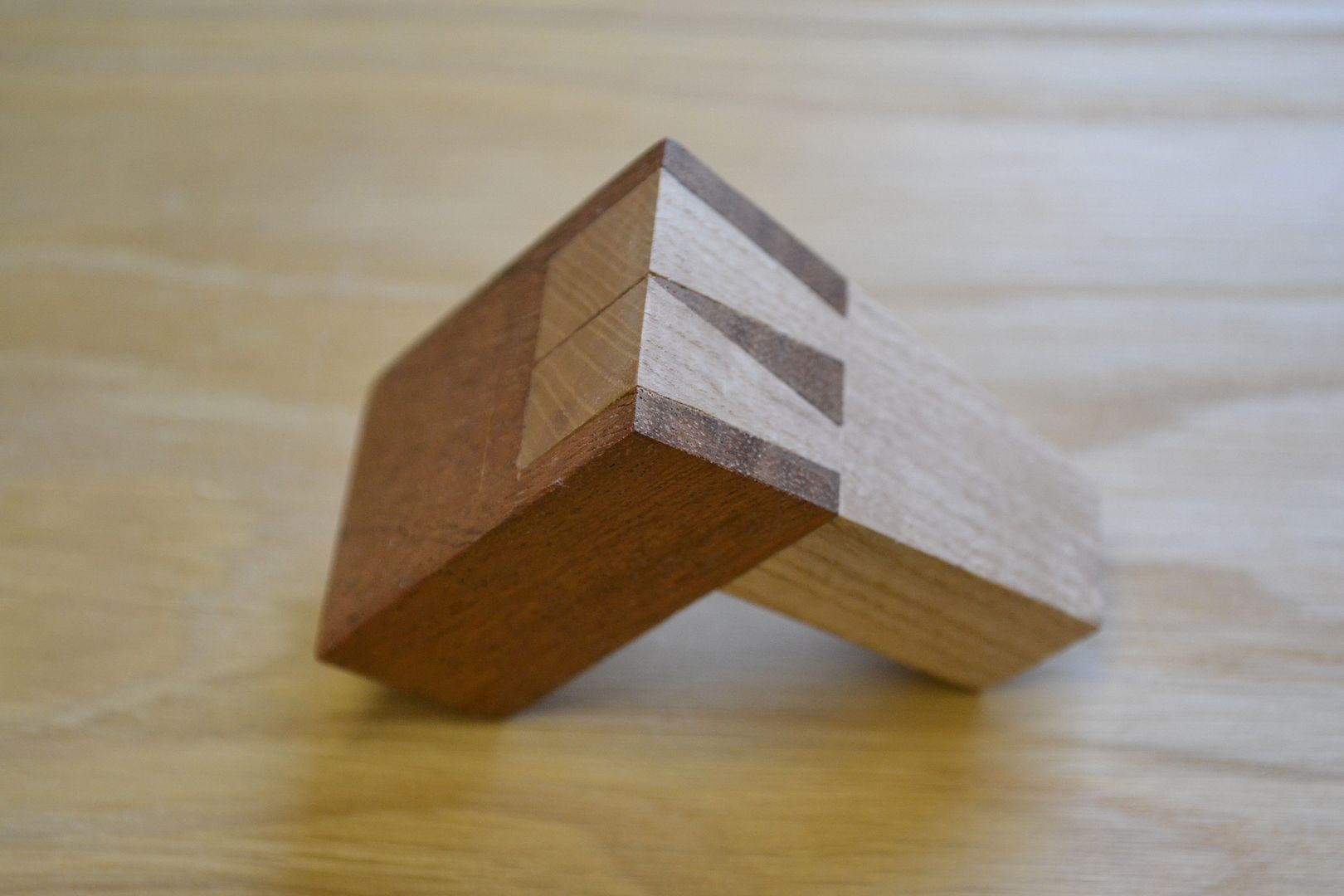

Made this little baby today out of some reclaimed sapele and ash.

You can use it as a template to mark out your tails and it also could be used as a saw guide made it the same size as the tails i had to cut . Its a 1.6 pitch for softwood.

Cheers Bern

You can use it as a template to mark out your tails and it also could be used as a saw guide made it the same size as the tails i had to cut . Its a 1.6 pitch for softwood.

Cheers Bern