Part - 1

Inn life there’s a first time for everything and in this case it’s my first time with a woodworking tool custom-made by a small family business and I've been eager to find out what he’s come up with. Just for the record Shane has be lending his saws out to anyone who wants a go, for free. A few UK tool sellers are offering this and I hope it continues. I feel it means a greater breadth of experience is applied to any “review” and helps cut through the “wow look at the new shiny thing” that we can all suffer from. Also, I’ll just make one further thing clear: You don’t need this saw to cut great joinery. Comfortable and sharp, the two key ingredients for great work, can be found in humble tools. I should know; my normal DT saws of choice are a Zona and less-than-pretty Spear & Jackson – but that is not the point of tools like this. The reason that someone wants to purchase the work of someone like Shane is for the attention to detail and the appreciation of craftsperson. So then let us focus on that, as it is those factors I feel that will set it apart.

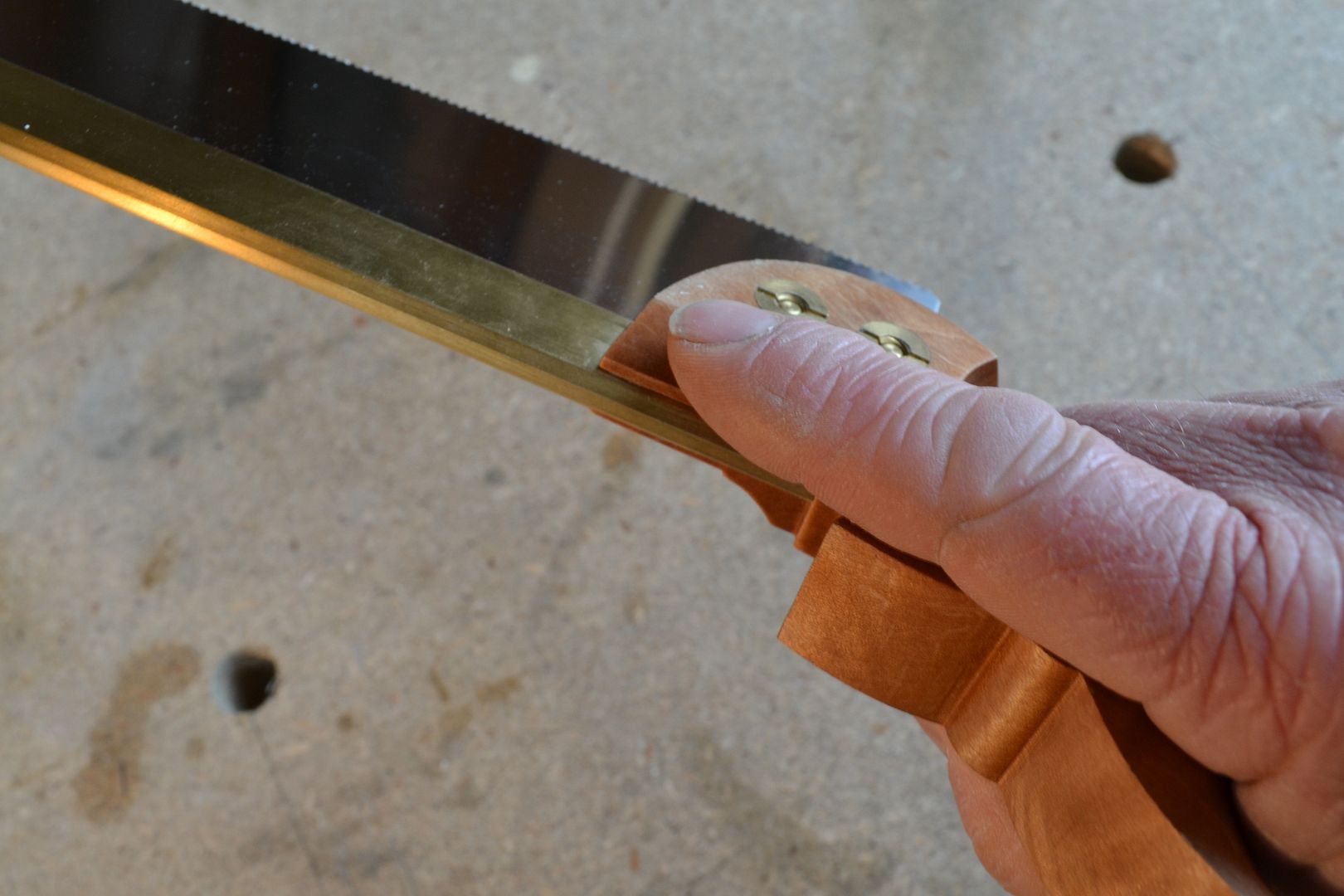

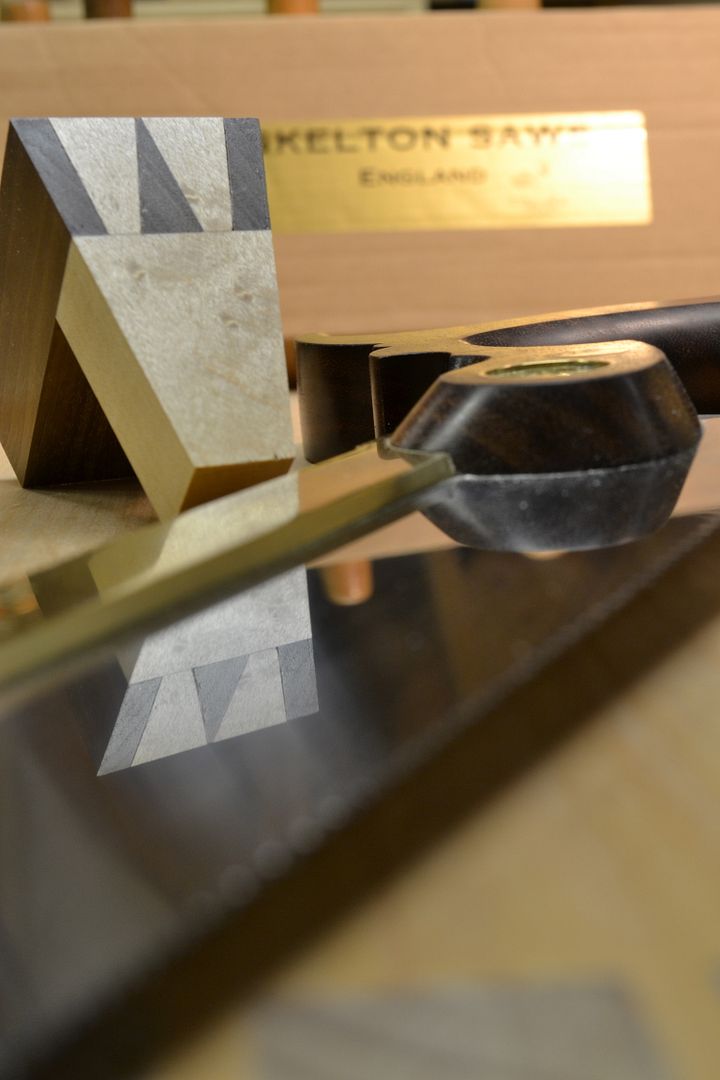

The design inspiration for the saw is from the 18th century, a wise place to start. The finish and presentation are of the highest order, and the saw is very nicely packed with a useful guide for those who need one. The medallion is attractive and features a peacock with a beak full of oak leaf and acorns; sounds odd, looks cool. I think I need a coat of arms, perhaps a cream tea, or a pint of cider, anyway…..The split nuts are dressed and fit perfectly with the rosewood grip. I’ve become aware that my assumed “medium-sized” hands are more like medium/small. No matter; the saw is comfortable and would take a larger hand than mine. It invites a proper position of all the digits. The grip is completely handmade from Rosewood and is a tribute to the care that has gone into making it.

Although very comfortable, the only area I felt could have been improved was the transition from the sides to the of the grip into the curved areas. The transition is just a little to obvious. If it was one of my daily users I would rub it with a rasp – but that’s not something I would want to attempt on a custom-made saw, More likely, I’d discuss it with the maker so they could maintain the flawless look. The image below might just help illustrate what I mean. I know I’m being critical, but comfort is such a key factor for me. See if you can spot it when contrasted with my Dad’s tenon saw.

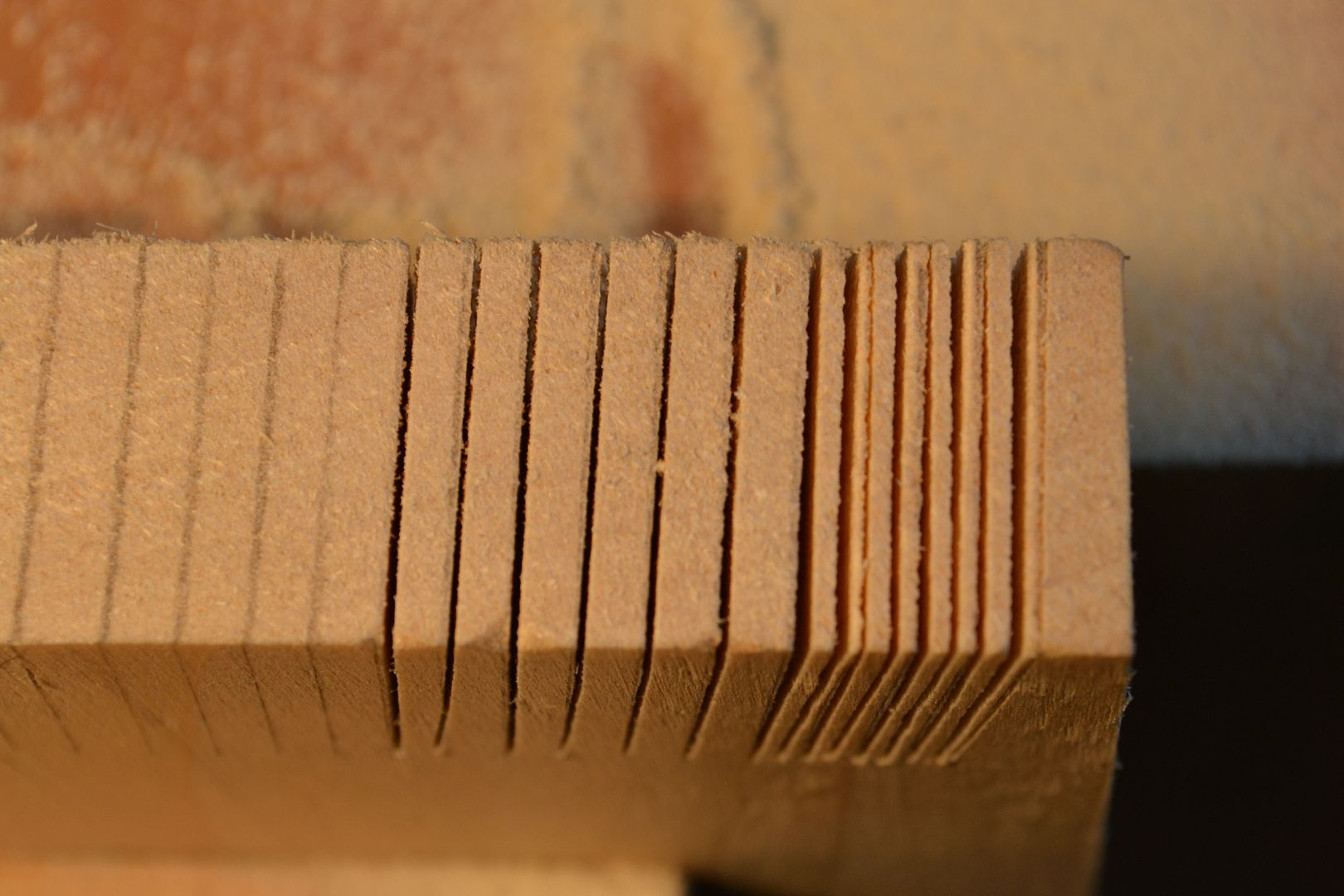

The sawplate is high quality Swedish steel and is brilliantly sharp. The back is solid brass rather than folded, and stamped with the Skelton name. On lovely aspect of the handle is how it flows into the brass back, which terminates into the handle with intended and perfect union.

I’ll hold off from too much of the how it in use until next time, but there will be no surprises. Due to its substantial back and super-sharp teeth, you saw by the book: light to virtually no pressure and simply steer it.

After my short time with the saw I did further appreciate that for those who do buy tools of this nature, there is in addition to proper function a degree of art and appreciation that is very enjoyable. As I alluded to at the start, it will not cut your joinery any better or make you a master woodworker – but it won’t make your joinery worse and potentially you’ll be enjoying the journey all the more. Next time, the important stuff: making something with it.

PS, Part 2 will indeed cover more of the factors involved in how the saw works such as the weight, balance and how it is sharpened. I will be very reluctantly sending this one back to you shane!