9fingers

Established Member

I've just completed the next mod to my table saw.

Machines with cast iron tables always run the risk of the dreaded rust. Keeping them waxed is a good precaution but if they have to live in an unheated workshop with changes in humidity rust can still happen.

I have a number of metal working machines and I arrange to heat the machine very slightly. All that is needed to prevent the condensation which leads to rust is to keep the surfaces slightly warmer than the surrounding air.

My engineering lathe is nearly 30 years old and not a rust mark anywhere and the mill is a little newer at 22 years and in similar condition.

The heaters are made from aluminium clad resistors powered from a low voltage power supply. This could be something like a car battery charger or whatever else is around

Typical power per machine is between 20-50 watts ie less than a lightbulb and you don't need to run it in the summer months.

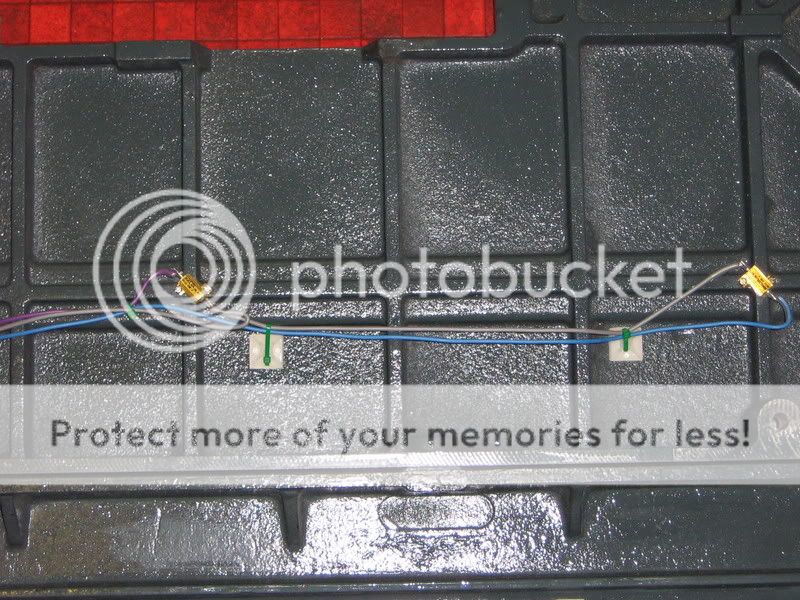

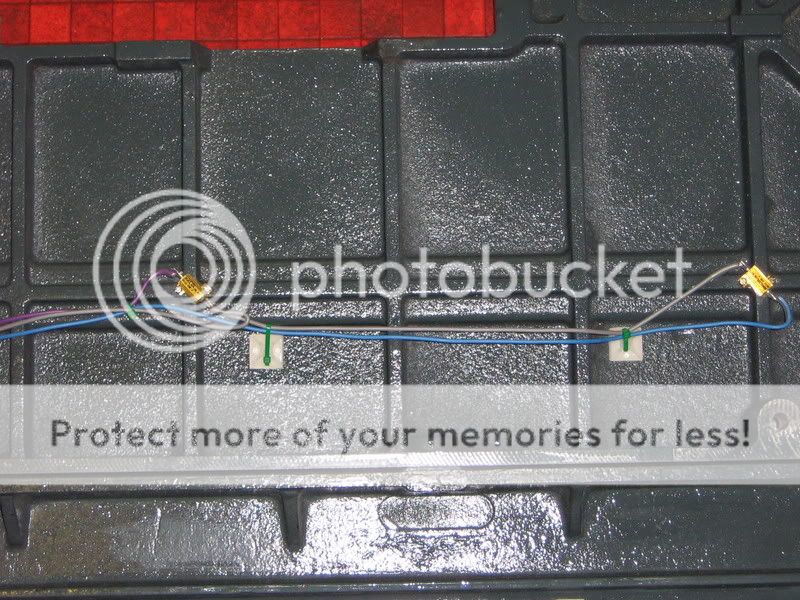

Here are some photos of resistors screwed onto the underside of the Xcalibur table and extension wings. Having a number of heaters helps the power to be changed by altering the series/parallel wiring as well as distributing the heat over the whole table. Cast iron is a poor conductor of heat so heat applied to a single point will not spread readily across the whole table.

I've got 8 x 15 ohm resistors which I will run from around 12 volts which will give a maximum of nearly 80 watts but I doubt if I'll need all this so I can turn down the power by using a lower voltage or changing the connections. This is why I've brought out so many wires.

If anyone want any more info then just ask

Regards

Bob

Machines with cast iron tables always run the risk of the dreaded rust. Keeping them waxed is a good precaution but if they have to live in an unheated workshop with changes in humidity rust can still happen.

I have a number of metal working machines and I arrange to heat the machine very slightly. All that is needed to prevent the condensation which leads to rust is to keep the surfaces slightly warmer than the surrounding air.

My engineering lathe is nearly 30 years old and not a rust mark anywhere and the mill is a little newer at 22 years and in similar condition.

The heaters are made from aluminium clad resistors powered from a low voltage power supply. This could be something like a car battery charger or whatever else is around

Typical power per machine is between 20-50 watts ie less than a lightbulb and you don't need to run it in the summer months.

Here are some photos of resistors screwed onto the underside of the Xcalibur table and extension wings. Having a number of heaters helps the power to be changed by altering the series/parallel wiring as well as distributing the heat over the whole table. Cast iron is a poor conductor of heat so heat applied to a single point will not spread readily across the whole table.

I've got 8 x 15 ohm resistors which I will run from around 12 volts which will give a maximum of nearly 80 watts but I doubt if I'll need all this so I can turn down the power by using a lower voltage or changing the connections. This is why I've brought out so many wires.

If anyone want any more info then just ask

Regards

Bob