DiscoStu

Established Member

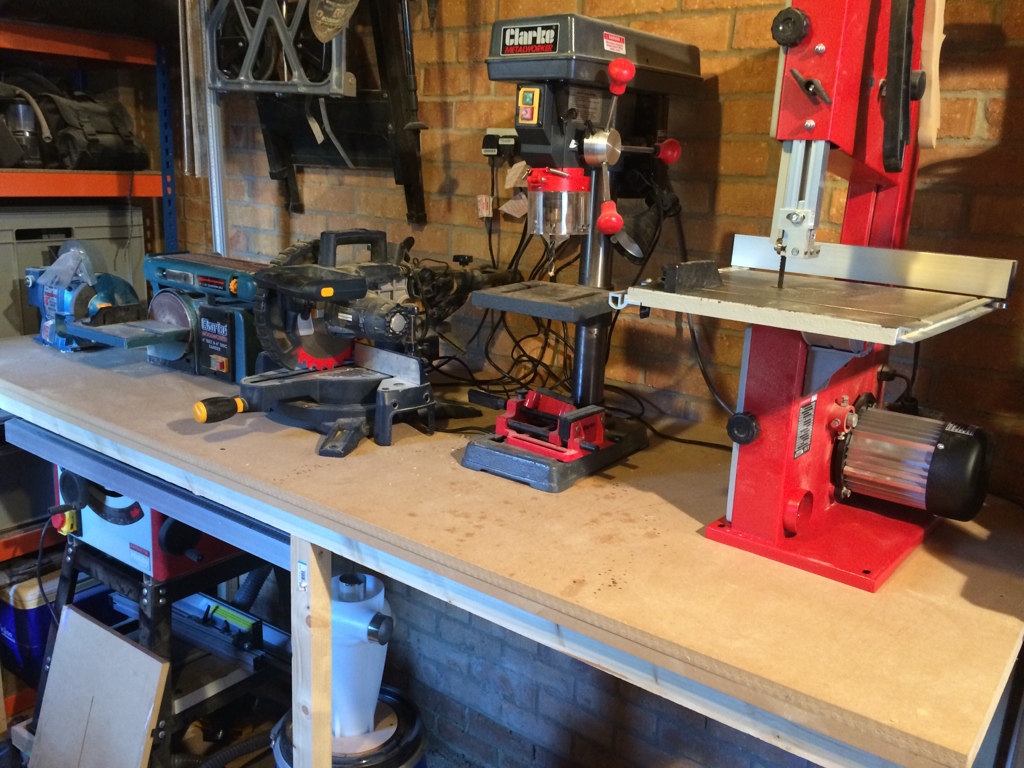

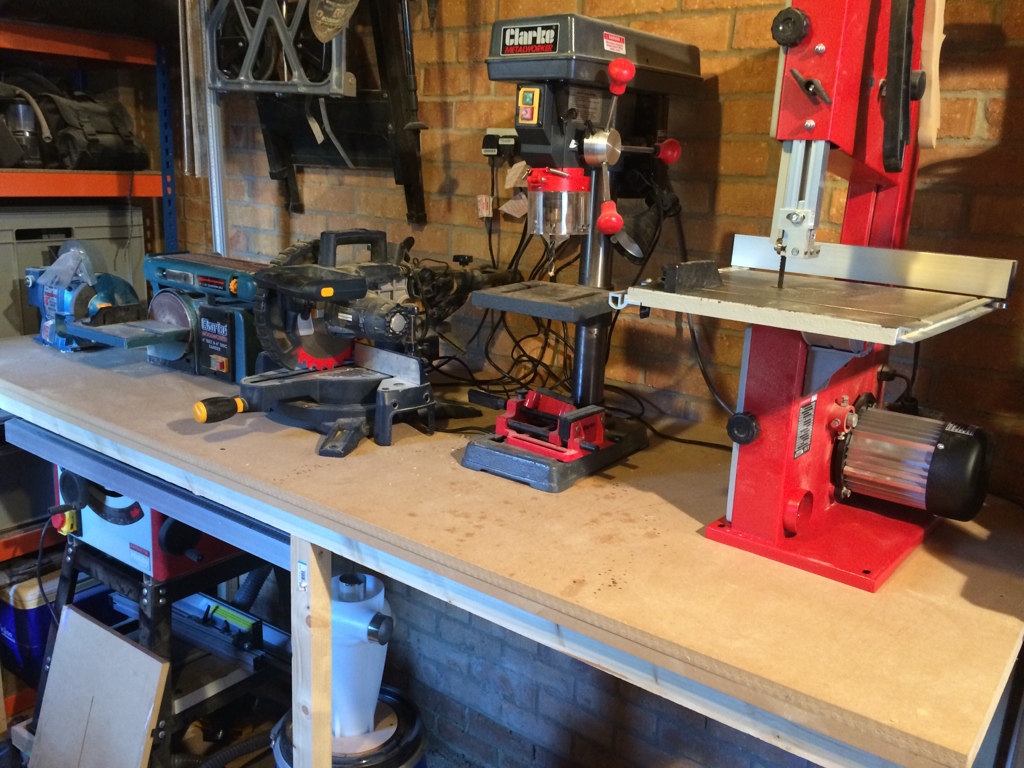

I've been gradually making some progress on my workshop.

It's really a woodworking workshop, but I do also have a tool chest for my mechanical tinkering.

Thought I'd share some photos.

So this is in a single garage.

All along one wall. Starting on the right:

Then

And then at the far end

I've still got to get the cyclone and dust extraction sorted for the bench tools.

I'm finding that I'm not using my TS200 table saw as much as I would like to / should do as it's not that accessible and needs a lot of space. I am hopeful I can sort that.

I'd welcome comments and thoughts etc.

Oh and if you're wondering the flap in Pic 2 was to allow the CSMS to fit onto that work top. I don't really need it now.

I need to think about a router table and a small planner thicknesser. I think I also need to think about drilling some holes or possibly some t track in my main worktop so I can use clamps easily.

Let me know if you have any other thoughts or ideas.

It's really a woodworking workshop, but I do also have a tool chest for my mechanical tinkering.

Thought I'd share some photos.

So this is in a single garage.

All along one wall. Starting on the right:

Then

And then at the far end

I've still got to get the cyclone and dust extraction sorted for the bench tools.

I'm finding that I'm not using my TS200 table saw as much as I would like to / should do as it's not that accessible and needs a lot of space. I am hopeful I can sort that.

I'd welcome comments and thoughts etc.

Oh and if you're wondering the flap in Pic 2 was to allow the CSMS to fit onto that work top. I don't really need it now.

I need to think about a router table and a small planner thicknesser. I think I also need to think about drilling some holes or possibly some t track in my main worktop so I can use clamps easily.

Let me know if you have any other thoughts or ideas.