You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SIP tablesaw rip fence query

- Thread starter bookman

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have now fitted the new blade — an 80 tooth from Summit. It is ok, but no better than that, there is still some feathering of softwood although using a sacraficial piece of wood behind the object to be cut helps a lot. Is this normal in your experience? The blade required a reducing bush which came with the blade, but the bush is actually thinner than the blade and is a rather sloppy fit. I had to fit the blade a couple of times before I got it working with a minimum of wobble. This blade gets a little noisy with a fairly high-pitched wine/scream, but this is not unbearable.

DaveL

Established Member

That does not sound right. I have an old Wadkin that has a 5/8" arbour, I use the Trend bushes on a number of different blades, the bush is a snug fit in the blades. I usually fit then by laying the blade on the side of a sledge hammer, offering the bush up to the bore, placing a steel block on the bush and applying a smart tap with a 1lb hammer. There should be no wobble.bookman":195iqj5j said:The blade required a reducing bush which came with the blade, but the bush is actually thinner than the blade and is a rather sloppy fit. I had to fit the blade a couple of times before I got it working with a minimum of wobble.

This may be due to the blade not running true, but some blades have slots cut in then to reduce noise, I recall seeing some with copper slugs fitted part way along the slots to damp the ringing noise from the blade. Does the blade have a max rpm marked on it, are you running it over speed?bookman":195iqj5j said:This blade gets a little noisy with a fairly high-pitched wine/scream, but this is not unbearable.

mailee

Established Member

I agree that the blades do sing quite a bit Mine do also. As to the 80 tooth blade yes it is for crosscutting and not ripping where a course blade is required. There are general purpose blades but these are not as fine as an 80 tooth. :wink:

OLD

Established Member

The bush from axminster is fully machined and thicker the summit is stamped out .If the fence is not inline or set slightly away from the blade the back rising teeth can mark the cut surface, easy to test for. you can also adjust the riving knife to apply slight pressure to hold work away from rear teeth

Again, thanks for all your help. The blade is a Summit part no. 193, you will find it here: http://www.summitsawblades.co.uk/saw_blade_193.htm you are right it has zero rake. It is rated at 6000 rpm, so no problem there.

DaveL's comment regarding tapping in the bush is interesting as the stamped aluminium one supplied with the blade will easily slip through the hole. It has no teeth on it to grip the blade at all. This will no doubt contribute to the small amount of blade wobble I am getting. (Not much point supplying something that doesn't fit properly Mr. Summit!) I can try the Draper bushes which are the correct size etc. but I wonder if I should be looking for "proper" machined bushes? DaveL seems to be happy with the Draper ones.

I wonder if Old could expand a bit about adjusting the riving knife. Do you mean to make the knife slightly out of alignment to the blade so it pushes the wood away?

Have just bought some nice oak today for a very small project so I'm anxious the get the saw set up as near to perfect as I can and then hopefully admire the results!

DaveL's comment regarding tapping in the bush is interesting as the stamped aluminium one supplied with the blade will easily slip through the hole. It has no teeth on it to grip the blade at all. This will no doubt contribute to the small amount of blade wobble I am getting. (Not much point supplying something that doesn't fit properly Mr. Summit!) I can try the Draper bushes which are the correct size etc. but I wonder if I should be looking for "proper" machined bushes? DaveL seems to be happy with the Draper ones.

I wonder if Old could expand a bit about adjusting the riving knife. Do you mean to make the knife slightly out of alignment to the blade so it pushes the wood away?

Have just bought some nice oak today for a very small project so I'm anxious the get the saw set up as near to perfect as I can and then hopefully admire the results!

DaveL

Established Member

bookman":2tupda3e said:DaveL seems to be happy with the Draper ones.

While I do have stuff from Draper, the bushes came from Trend.

Malcolm R said:Sorry Malcolm, you've lost me. Could you explain a bit more? I'm not sure what you mean ...

Apparently the people at SIP fit a device to the riving knife to stop kick back these days. I think they have to do this to comply with some sort of regulation. They have no knowledge of the extra bit of rip fence or the bolts to secure it.

Malcolm R

Member

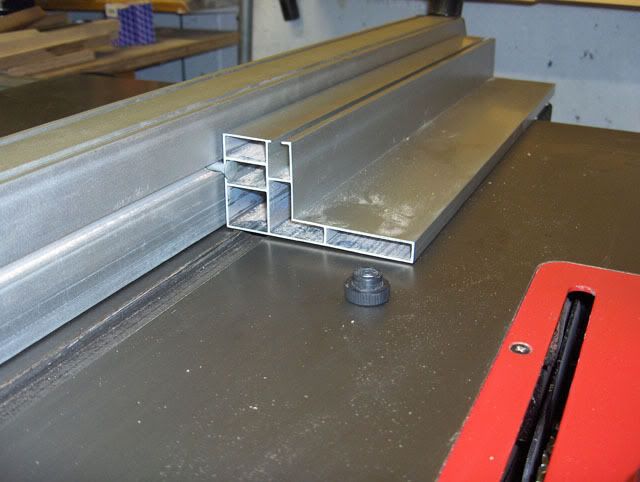

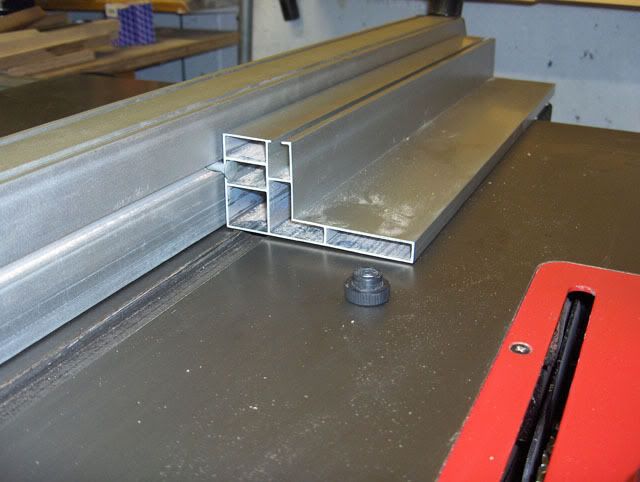

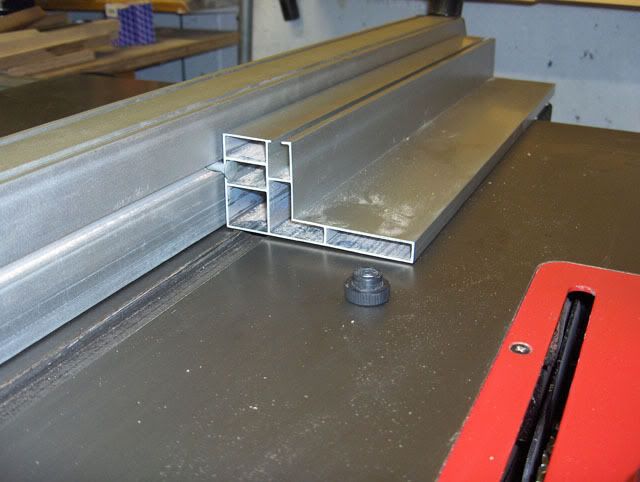

This is a picture of the auxiliary fence for the saw. I have not fitted it fully so you can see the bolt that holds it to the main fence and the black knob you see goes on the bolt to tighten the whole thing up.

Hope this helps.

Hope this helps.

Malcolm R

Member

I do use it reasonably often. The main uses are when cross cutting with the mitre gauge or ripping thin strips as the crown guard is fairly wide so this allows me to get the fence closer to the blade and keep the guard on.

Looking at your earlier posts, you seem to have the auxiliary fence but not the bolts. A couple of suitably sized bolts and knobs should do (washers and wing nuts if you are stuck). You might need to file the heads slightly to make them more rectangular but they are not far off hexagonal so it shouldn't be a big job.

Malcolm

Looking at your earlier posts, you seem to have the auxiliary fence but not the bolts. A couple of suitably sized bolts and knobs should do (washers and wing nuts if you are stuck). You might need to file the heads slightly to make them more rectangular but they are not far off hexagonal so it shouldn't be a big job.

Malcolm

Malcolm R":1beu070y said:This is a picture of the auxiliary fence for the saw. I have not fitted it fully so you can see the bolt that holds it to the main fence and the black knob you see goes on the bolt to tighten the whole thing up.

Hope this helps.

It might be just me, but I can't see how that knob fits on the end of the bolt. :-k :?

motownmartin

Established Member

It probably goes all the way through the fence :? :-k I can't see another way, I am thinking that the bolt is fitting into a slot, dunno.

Malcolm R

Member

motownmartin":dyk3nd2t said:It probably goes all the way through the fence :? :-k I can't see another way, I am thinking that the bolt is fitting into a slot, dunno.

Sorry, should have made it clearer. The head of the bolt is held in the slot on the auxiliary fence. The bolt then goes through the main fence and the knob is then on the other side of the fence.

I photographed it like this to let Bookman see the different parts and how they fit together.

Malcolm

Similar threads

- Replies

- 6

- Views

- 435

- Replies

- 18

- Views

- 7K

- Replies

- 8

- Views

- 2K

Latest posts

-

-

-

-

-

Is it worth buying premium tools if you don't use them enough ? Metabo grinder.

- Latest: Not-Entirely-Useless

-

-

-