swagman

Established Member

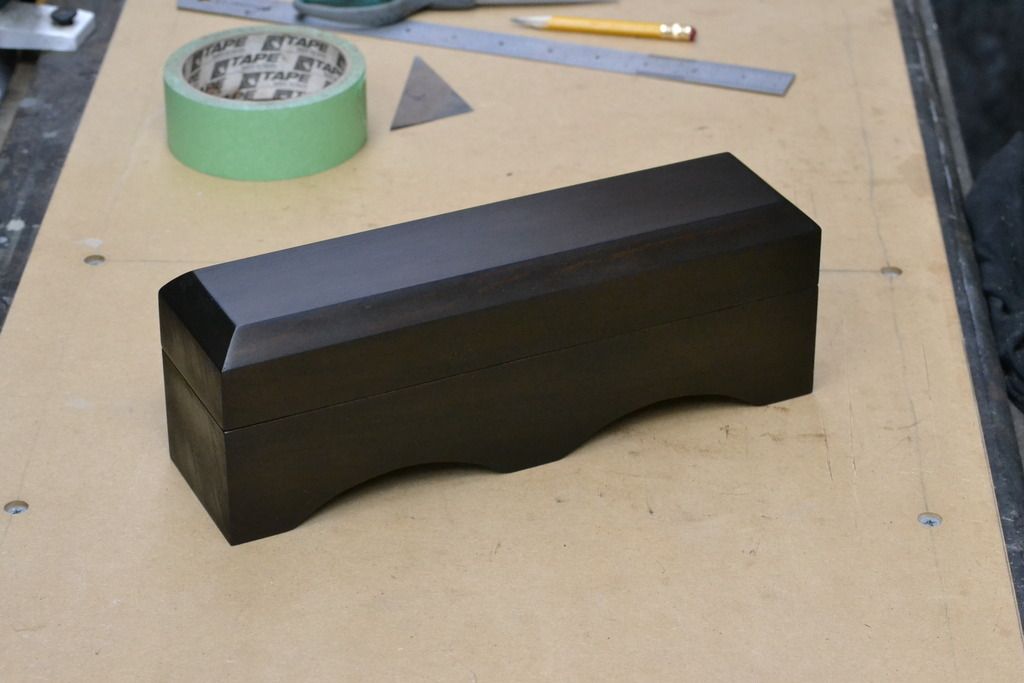

The following is an update on the box I am making for my Welsh Llyn Idwell Grecian Stone.

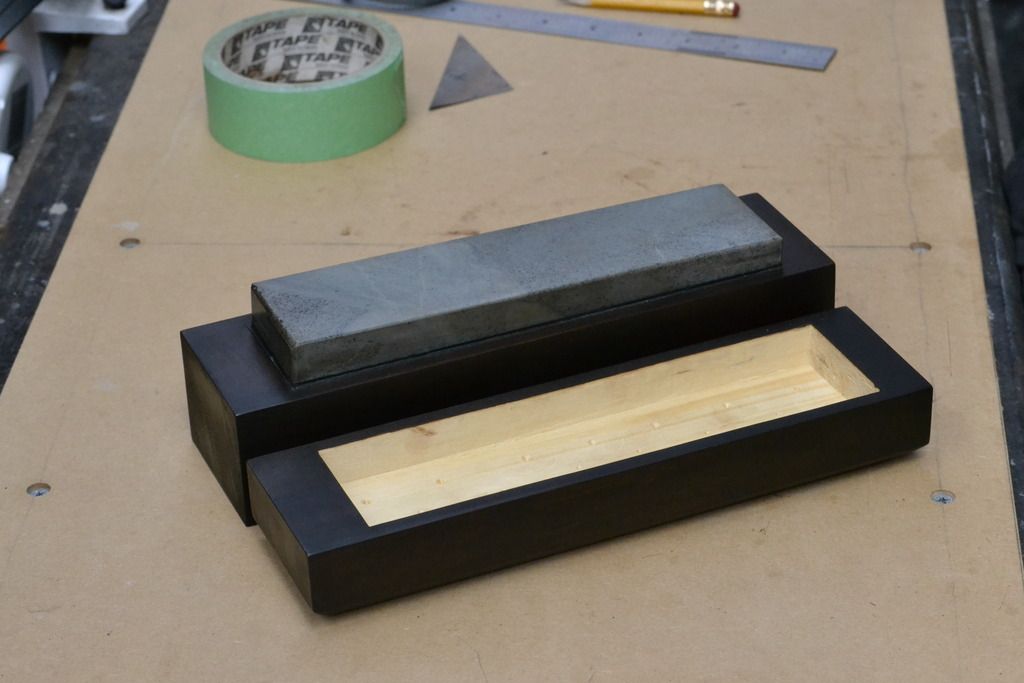

The box after being mortised out and spirit stained ready for the stone to be seated. The timber used is Tasmanian Huon Pine.

http://www.wood-database.com/huon-pine/

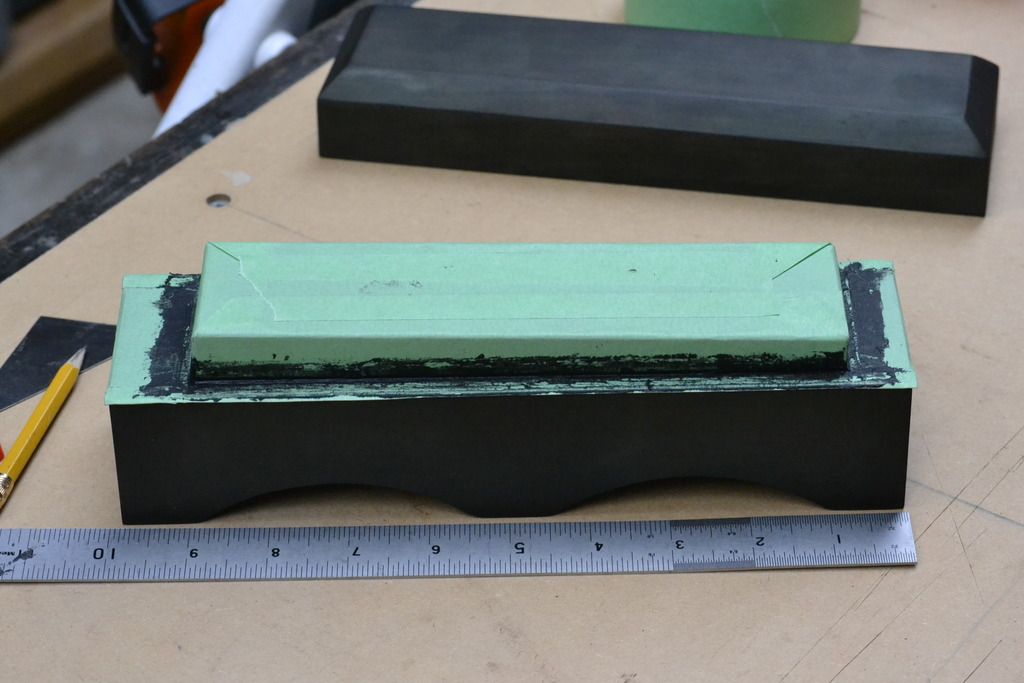

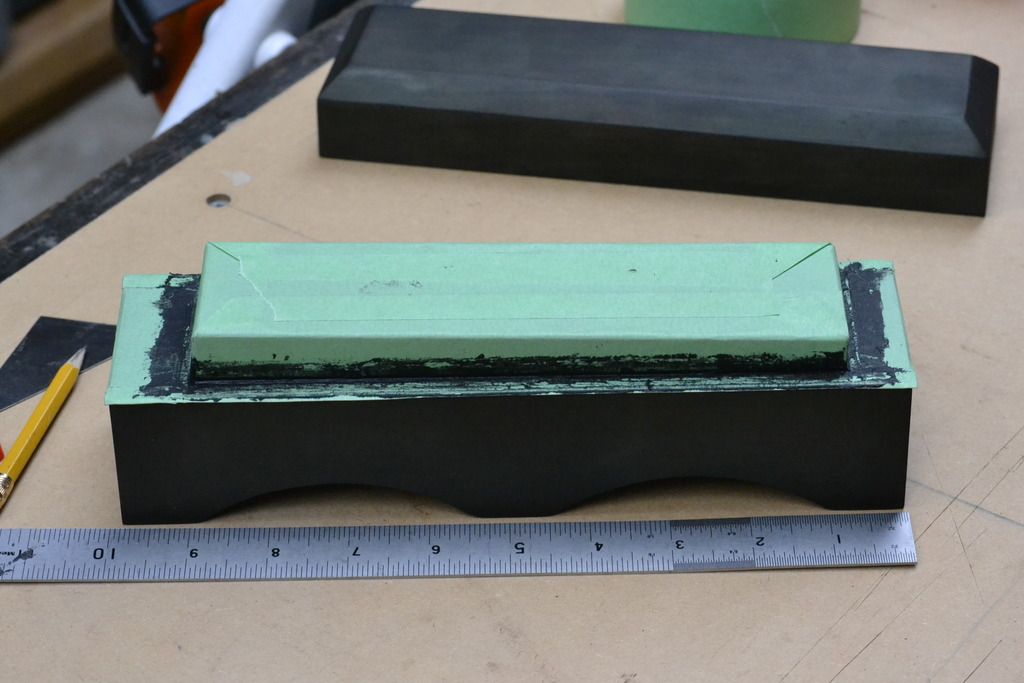

A black caulking is used to seal the stone within its mortised housing.

Tomorrow I can apply 2 coats of wax to the stained surface and buff it to a respectable sheen. Final photo to submit.

If any other members have recently made a box to house their sharpening stones, your quite welcome to add your own photo's.

Stewie;

The box after being mortised out and spirit stained ready for the stone to be seated. The timber used is Tasmanian Huon Pine.

http://www.wood-database.com/huon-pine/

A black caulking is used to seal the stone within its mortised housing.

Tomorrow I can apply 2 coats of wax to the stained surface and buff it to a respectable sheen. Final photo to submit.

If any other members have recently made a box to house their sharpening stones, your quite welcome to add your own photo's.

Stewie;