adzeman

Established Member

Breaking off from my own project of producing a base for my planer/thicknesser, protection for dryer and storage for my wood moulding planes with the addition of a router lift, is the moving and repair of my daughters cedar greenhouse to a new allotment site.

First two days spent dissembling.

Next two days transporting to new allotment site.

Remaining two days digging and concreting by hand the foundations.

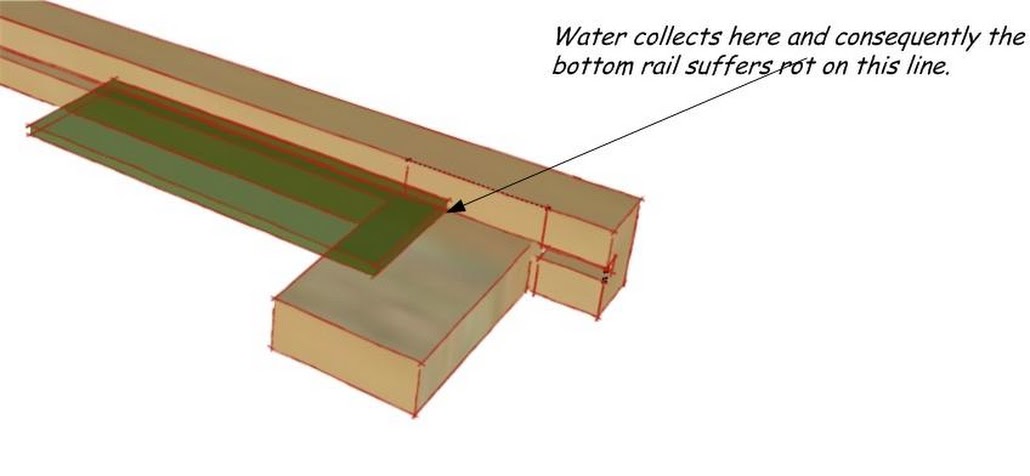

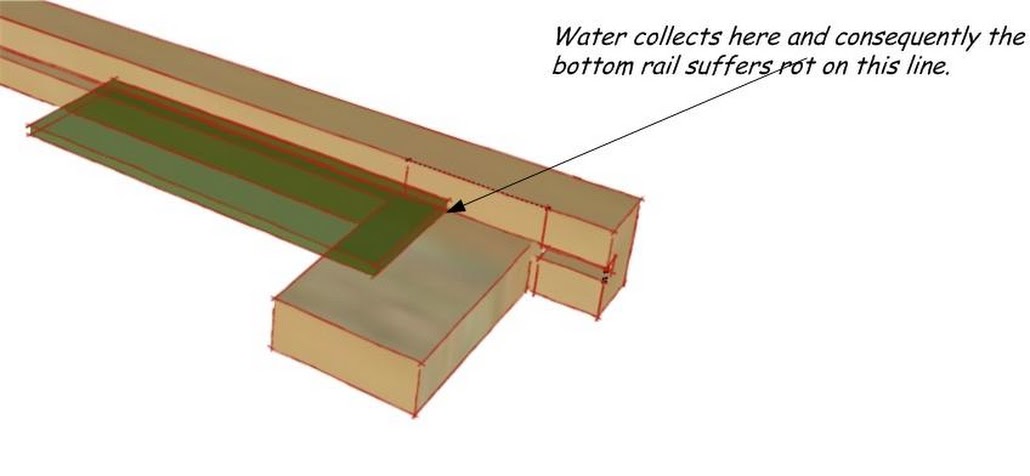

I am now in the process of inspecting and deciding what parts can be saved and which require replacement and are there any improvements I can make? Not an easy thought process. In general the cedar is still sound but very dry. Most of the rot is in the roof frames on the bottom rails due to the glass not overhanging.

I need to state at this point that this make of greenhouse is not cheap. To buy this model would cost £1,240.00

The joints are dry, originally tight and secured with aluminium star dowels and the centre mullion secured by a steel screw.

Stripping and disassembly was simple and when the star dowel was cut through with a junior hacksaw the frame came apart.

The roof frames were in two parts a large one and a small one. The large one is exactly double the size of the small one ie. defined by the size of the glass sheet for a 730mm wide pane.

Of one large roof frame only one timber member, the top rail could be re-used. All the other parts were made from one 200 x 50 x 3.000 of softwood. Cost £5.00

As in the prototype I kept the joints tight and secured with star dowels.

First two days spent dissembling.

Next two days transporting to new allotment site.

Remaining two days digging and concreting by hand the foundations.

I am now in the process of inspecting and deciding what parts can be saved and which require replacement and are there any improvements I can make? Not an easy thought process. In general the cedar is still sound but very dry. Most of the rot is in the roof frames on the bottom rails due to the glass not overhanging.

I need to state at this point that this make of greenhouse is not cheap. To buy this model would cost £1,240.00

The joints are dry, originally tight and secured with aluminium star dowels and the centre mullion secured by a steel screw.

Stripping and disassembly was simple and when the star dowel was cut through with a junior hacksaw the frame came apart.

The roof frames were in two parts a large one and a small one. The large one is exactly double the size of the small one ie. defined by the size of the glass sheet for a 730mm wide pane.

Of one large roof frame only one timber member, the top rail could be re-used. All the other parts were made from one 200 x 50 x 3.000 of softwood. Cost £5.00

As in the prototype I kept the joints tight and secured with star dowels.