There have been a number of posts regarding the the need to ensure that the mitre slot is parallel with the blade on a table saw. Indeed it is highly desirable to do this to stop burning and to keep the kerf to a minimum in a partial cut, but it does not have any influence on the angle of the cut. The only aspect this affects the angle of the cut is the relationship between the miter fence and the mitre slot. Even if the miter slot was say 10 degrees out from the blade, as long as the mitre fence is at 90 degrees to the mitre slot in the table, the cut will still be at 90 degrees. You probably know this its just that a couple of members were having trouble achieving 90 degree cuts and were spending time trying to adjust the table top to eliminate the error.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mitre slot

- Thread starter newt

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

as my Sense would say ... 'Mistake' !

no - exaggerate a bit more - if your mitre slot was 45 out, so you set the mitre gauge to 45 - your gauge is now parallel to the blade

BUT !!!

your slot is not, and you are pushing the wood into the side of the blade at an angle of 45 - 'Very Bad'

no - exaggerate a bit more - if your mitre slot was 45 out, so you set the mitre gauge to 45 - your gauge is now parallel to the blade

BUT !!!

your slot is not, and you are pushing the wood into the side of the blade at an angle of 45 - 'Very Bad'

Tusses, If the slot is at any angle and the mitre fence is set at 90 degrees to the mitre slot the cut will still be 90 degrees. Try this take the mitre gauge out of the slot, place a piece of stock that has been cut at 90 degrees against the mitre gauge, with the saw disconnected, hold the gauge at some angle with the cut edge touching the blade, move the mitre gauge along your chosen angle and you will see the blade contacts along the 90 degree cut edge.

Chems

Established Member

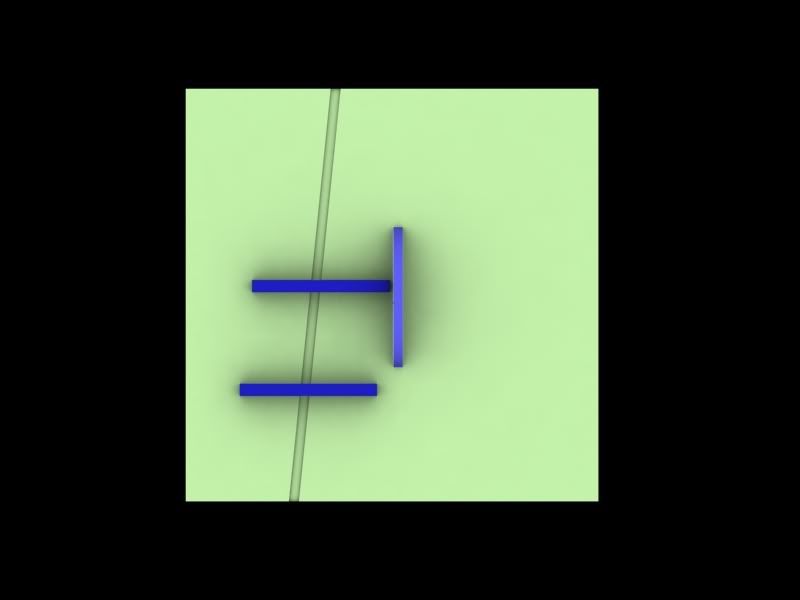

Your incorrect there newt as your making the cut either longer or shorter as the track and mitre gauge are going to be getting closer to the blade. So the angle may stay the same but the actual piece is going to be pushed into the side of the blade, your effectively going to stop the blade. Huge dramatization on this picture here but I think it clearly shows, 2 miter fences in place and look how close the second one is.

Chems, but you have not got the mitre gauge set 90 degrees to the mitre slot, that is the main point. Take a router table does it matter where the mitre slot is the only thing that affects a 90 degree cut is the relationship between the angle of the mitre gauge and the mitre slot. In fact if the slot on a table saw was in front of the blade and at 90 degrees to the blade it would still produce a 90 degree cut, well cut may not be the right word.

Chems, a further point, in your drawing you have the slot angled towards the blade, if you were to cut in this situation it would be the back teeth of the blade that would make contact. However it would still be a 90 degree cut (well scrape) if the gauge was set at 90 degrees with the slot.

How do you import a microsoft word drawing into the forum reply box?

How do you import a microsoft word drawing into the forum reply box?

TheDudester

Established Member

newt":3tvc4g96 said:....Even if the miter slot was say 10 degrees out from the blade, as long as the mitre fence is at 90 degrees to the mitre slot in the table, the cut will still be at 90 degrees. You probably know this its just that a couple of members were having trouble achieving 90 degree cuts and were spending time trying to adjust the table top to eliminate the error.

Pete

Don't you mean 90 degrees to the blade?

Regards

D

newt":3b1dqxqn said:Chems, a further point, in your drawing you have the slot angled towards the blade, if you were to cut in this situation it would be the back teeth of the blade that would make contact. However it would still be a 90 degree cut (well scrape) if the gauge was set at 90 degrees with the slot.

How do you import a microsoft word drawing into the forum reply box?

the drawing shows a slot that is not parallel to the blade, allbeit exaggerated. which is what your first post is about.

You still dont get it, it seems. if you make a cut like this it would be dangerous in terms of kick back as the back of the blade will grab hold of the wood. if the error is small enough that you could 'force' the wood _all the way_ past the blade then you are correct - the cut would would be 90. in practice , the front of the blade will be cutting and the back of the blade would be cutting again which would leave a step if you diddn't finish the cut past the back of the blade. and if you did, then your finished size would be to the second cut that the back of the blade made - which would be too small !

Chems

Established Member

Newt I think you may have a mental block about this, if in my picture the mitre gauge was at 90 degrees to the track rather than the blade, the effect would still be the same.

I know if I did this on my table saw the wood would just stop the blade from spinning after the first few cm.

I know if I did this on my table saw the wood would just stop the blade from spinning after the first few cm.

Hi Pete

I wanted to step in earlier but, with my English and without pictures, you would go to the router table...

First, yes - the miter gauge fence must be at 90° to the miter slot (or miter bar), to get a 90° cut.

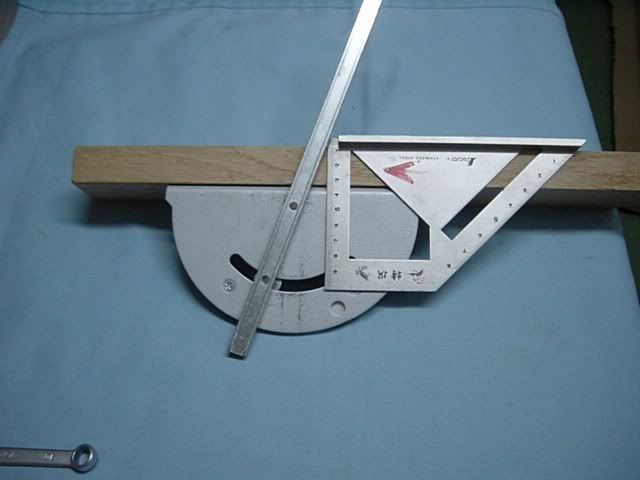

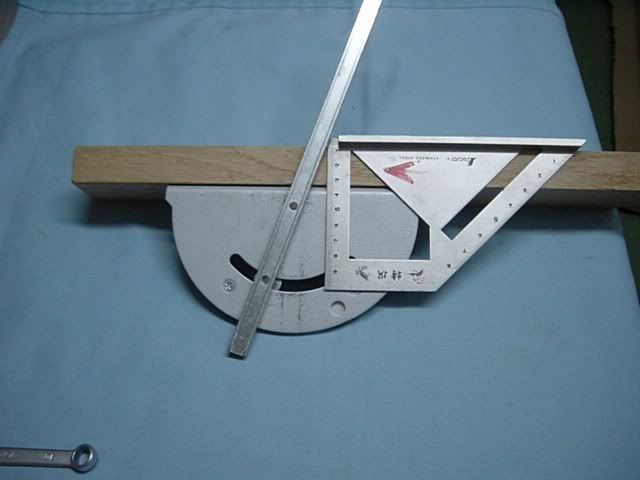

I think that the picture will show it very clearly (exaggerated of course).

Loosen the nuts on the miter gauge (MG) but not too loose, leave some "friction" so it will not move too easy.

Take a good try-square and attach it to the MG fence

Push the MG bar till the try-angle "clicks" iron-to iron.

You can check it also from the other side

And while holding it, tight the nuts

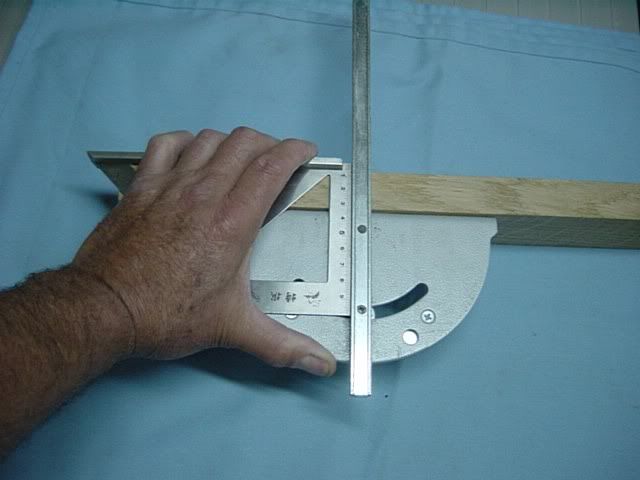

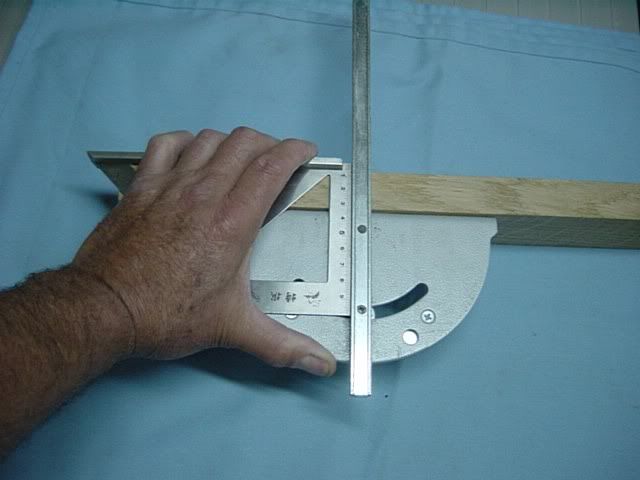

Put the MG in the slot and take one long plastic triangle (I found them very accurate and they don't have "moods" because of temp. changes)

For better clarity (contrast) I'll show it with my "copy & past" triangle.

Hold the triangle attached to the MG fence

Move it slowly while putting your finger in the slot and "filling" that the triangle is in-line with the slot edge

Now move your finger to the far end...

What the eye cannot see - the finger can feel......

But my best method is to use one of those specially made "miter slot bar"...the bar fits more than snugly to the slot (I have to force it in) and I'm using it while adjusting/checking the blade/slot parallelism (a small deviation on 200mm will show much better on 600mm length)

Attach the triangle to the fence and believe me, you will see it...just release the nuts, set it and tight back the nuts

Regards

niki

I wanted to step in earlier but, with my English and without pictures, you would go to the router table...

First, yes - the miter gauge fence must be at 90° to the miter slot (or miter bar), to get a 90° cut.

I think that the picture will show it very clearly (exaggerated of course).

Loosen the nuts on the miter gauge (MG) but not too loose, leave some "friction" so it will not move too easy.

Take a good try-square and attach it to the MG fence

Push the MG bar till the try-angle "clicks" iron-to iron.

You can check it also from the other side

And while holding it, tight the nuts

Put the MG in the slot and take one long plastic triangle (I found them very accurate and they don't have "moods" because of temp. changes)

For better clarity (contrast) I'll show it with my "copy & past" triangle.

Hold the triangle attached to the MG fence

Move it slowly while putting your finger in the slot and "filling" that the triangle is in-line with the slot edge

Now move your finger to the far end...

What the eye cannot see - the finger can feel......

But my best method is to use one of those specially made "miter slot bar"...the bar fits more than snugly to the slot (I have to force it in) and I'm using it while adjusting/checking the blade/slot parallelism (a small deviation on 200mm will show much better on 600mm length)

Attach the triangle to the fence and believe me, you will see it...just release the nuts, set it and tight back the nuts

Regards

niki

All I am saying is the relationship of the mitre slot to the blade does not affect the angle of the cut, only the relationship between the gauge and the mitre affects the angle. If you look at Nikis first picture and imagine pushing the gauge not in the direction of the slot in the table but on a track that is a right angle with the gauge you can see that it will cut a right angle on the wood. I only mention this because someone was struggling to get a 90 degree cut by trying to move the table top with respect to the blade. By the way I am not suggesting that the blade should not be parallel to the slot it is essential it is to eliminate burning and binding.

Thank you Pete

By coincidence, I just replied to somebody in another forum that asked me about "accuracy of cut" if you like you can see my reply here....generally, it's exactly what you said...

http://www.sawmillcreek.org/showthread. ... post886686

Regards

niki

By coincidence, I just replied to somebody in another forum that asked me about "accuracy of cut" if you like you can see my reply here....generally, it's exactly what you said...

http://www.sawmillcreek.org/showthread. ... post886686

Regards

niki

newt":22ns1dc3 said:There have been a number of posts regarding the the need to ensure that the mitre slot is parallel with the blade on a table saw. Indeed it is highly desirable to do this to stop burning and to keep the kerf to a minimum in a partial cut, but it does not have any influence on the angle of the cut. The only aspect this affects the angle of the cut is the relationship between the miter fence and the mitre slot. Even if the miter slot was say 10 degrees out from the blade, as long as the mitre fence is at 90 degrees to the mitre slot in the table, the cut will still be at 90 degrees. You probably know this its just that a couple of members were having trouble achieving 90 degree cuts and were spending time trying to adjust the table top to eliminate the error.

Is this some sort of twisted logic? To produce a square cut the material must be at 90 to the blade if the mitre slot was off 10 degrees and the mitre fence at 90 to the slot you must surely get an 80 degree cut quickly followed by binding.

We then have Niki showing in great detail how to very accurately set the fence square to the slot

Of course if perhaps you meant something else?

Regards Tom

If you set the mitre fence at 90 degrees to the mitre slot and trim the end of a piece of timber on the correct side of the blade the result will be a 90 degree cut and no binding. Trust me, try it and see for yourself.

Roy.

Roy.

Chems

Established Member

Digit, unless Im reading your post completely wrong are you not just describing how to use a mitre slot, other than at 90 degrees for a straight edged cut how else would you use it?

I thought I understood what was been asked here, but Im so confused now. Im leaving and not coming back to this thread as it gives me brain ache.

I thought I understood what was been asked here, but Im so confused now. Im leaving and not coming back to this thread as it gives me brain ache.

Digit":2qthwskr said:If you set the mitre fence at 90 degrees to the mitre slot and trim the end of a piece of timber on the correct side of the blade the result will be a 90 degree cut and no binding. Trust me, try it and see for yourself.

Roy.

this is only true for a thin stick shaped piece of wood.

if you try to cut a 10" wide board with your mitre slot, then you will get binding.

Not if you read what I said. If you trim the END and do it on the CORRECT side of the blade the timber will be moving AWAY from the side of the blade, not towards it and as you are trimming the end there is nowt to bind.

Roy.

Roy.

Similar threads

- Replies

- 11

- Views

- 489

- Replies

- 6

- Views

- 1K

- Replies

- 12

- Views

- 1K