Hi,

I need some advice on how best to cut a riving knife out of 2mm mild steel sheet with the tools I have available; if it helped to do so, I could use as a template a prototype I have made out of 2mm aluminium. I cut the prototype (very slowly!) on a cheap scrollsaw with a ordinary 15tpi pin-ended blade (but I suspect this won't be up to cutting the steel), finished by hand filing; other likely power tools available to me include a jigsaw, a small dremel-type tool, a cheap bench grinder, a pillar drill. My metalworking skills/tools are limited.

The background is that I was persuaded by this recent thread

https://www.ukworkshop.co.uk/forums/home-made-table-saw-t61771.html

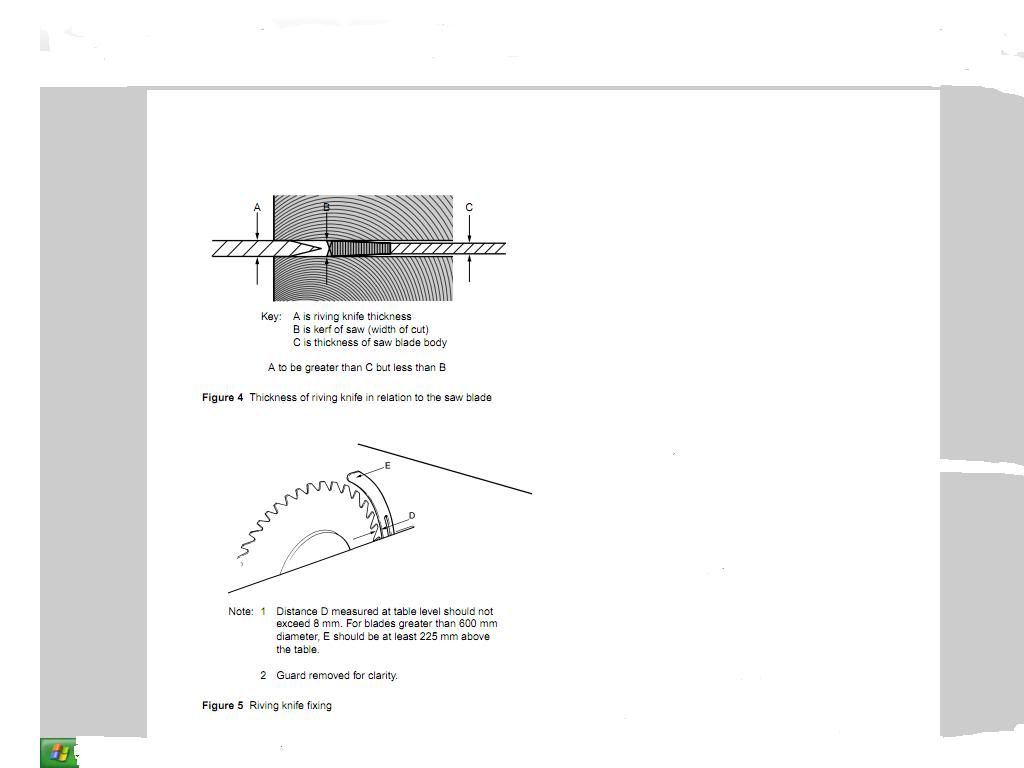

that I needed to improve the safety features on my home small made table saw (inverted 5" circular saw). The first step on this road will be to make a riving knife - the blade has a 1.6mm plate and a 2.4mm kerf, so 2mm sheet seemed reasonable. I made the prototype out of aluminium, and it fits well just a few mm behind the blade and co-planar with it. However, the 2mm aluminium is just too flexible - even though the prototype it is solidly bolted to the mounting stud designed to take the (missing) original riving knife, it doesn't take much pressure to deflect it laterally enough (I think) to let the cut material get caught by the rising back teeth. Hence the need to copy the shape in steel. The most challenging part will, I think, be to accurately cut the curve which sits behind the blade. On the prototype, it is an arc of a circle radius 68mm (so it sits just outside the 64 mm radius of the blade), the arc subtending about 120 degrees.

How can I cut this shape in 2mm mild steel - specifically, the circular arc? The remaining cuts are mostly straight & could be done with a hand hacksaw, but I don't think a hacksaw will negotiate the curve I need.

Any ideas gratefully received.

Thanks

Chris

I need some advice on how best to cut a riving knife out of 2mm mild steel sheet with the tools I have available; if it helped to do so, I could use as a template a prototype I have made out of 2mm aluminium. I cut the prototype (very slowly!) on a cheap scrollsaw with a ordinary 15tpi pin-ended blade (but I suspect this won't be up to cutting the steel), finished by hand filing; other likely power tools available to me include a jigsaw, a small dremel-type tool, a cheap bench grinder, a pillar drill. My metalworking skills/tools are limited.

The background is that I was persuaded by this recent thread

https://www.ukworkshop.co.uk/forums/home-made-table-saw-t61771.html

that I needed to improve the safety features on my home small made table saw (inverted 5" circular saw). The first step on this road will be to make a riving knife - the blade has a 1.6mm plate and a 2.4mm kerf, so 2mm sheet seemed reasonable. I made the prototype out of aluminium, and it fits well just a few mm behind the blade and co-planar with it. However, the 2mm aluminium is just too flexible - even though the prototype it is solidly bolted to the mounting stud designed to take the (missing) original riving knife, it doesn't take much pressure to deflect it laterally enough (I think) to let the cut material get caught by the rising back teeth. Hence the need to copy the shape in steel. The most challenging part will, I think, be to accurately cut the curve which sits behind the blade. On the prototype, it is an arc of a circle radius 68mm (so it sits just outside the 64 mm radius of the blade), the arc subtending about 120 degrees.

How can I cut this shape in 2mm mild steel - specifically, the circular arc? The remaining cuts are mostly straight & could be done with a hand hacksaw, but I don't think a hacksaw will negotiate the curve I need.

Any ideas gratefully received.

Thanks

Chris