Hi Guys,

I wonder if anyone can offer me some advice with a problem that I have with an Incra Ultra 25. I bought the Ultra about two months ago and have fixed it to my router table, I have checked that the table is flat and the fence of the Ultra is square to the table.

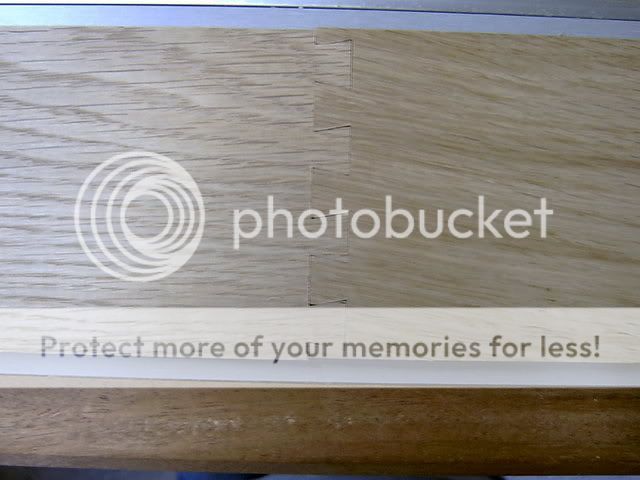

I made the dovetail bit and template selection according to the instructions, centred the bit and set the template accordingly. The stock used for centering and the test cuts is the same width and square, the bit height was set according to the instructions and a test cut was made (quite a few in fact) but the result is rather disappointing.

The depth of cut seems fine but there is a gap of approximately 3/64 of an inch between the mating edges of the dovetail. I can only eliminate this by moving the Ultra to the next position and then adjusting to remove the error but this is not how I expected the system to work.

Any ideasPic

I wonder if anyone can offer me some advice with a problem that I have with an Incra Ultra 25. I bought the Ultra about two months ago and have fixed it to my router table, I have checked that the table is flat and the fence of the Ultra is square to the table.

I made the dovetail bit and template selection according to the instructions, centred the bit and set the template accordingly. The stock used for centering and the test cuts is the same width and square, the bit height was set according to the instructions and a test cut was made (quite a few in fact) but the result is rather disappointing.

The depth of cut seems fine but there is a gap of approximately 3/64 of an inch between the mating edges of the dovetail. I can only eliminate this by moving the Ultra to the next position and then adjusting to remove the error but this is not how I expected the system to work.

Any ideasPic