RobertMP

Established Member

I've got some beech and am looking at getting started on the making of my table project.

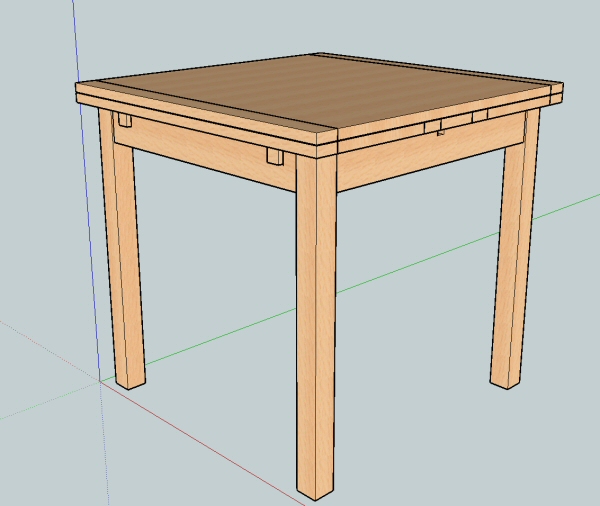

It will look something like this -

With breadboard ends on the main top and the pull out extensions. I know the problems with breadboard ends so I want to fake it rather than use solid wood.

I was thinking along the lines of resawing a planed surface off some planks down to say 5mm thick on the bandsaw then thicknessing them down to 3mm ready to stick onto 22mm MDF to give me a 25mm thick table top. The sides could be trimmed with the same or thicker and the ends could then have 'breadboards' fully glued on.

22mm MDF seems a bit hard to come by locally. 18mm would mean very thick 'veneer' is that a problem?

The other difficulty with thicknessing to 3mm is that my thicknesser stops at about 7mm so the 'veneer' would have to sit on top of a bit of say 12mm MDF to lift it up. I have done similar before on some thin strips. never tried it on something say 4" wide.

Just wondering what the best way is to go about this.

edit.

Oh and I have used bought veneered MDF before. I'm not considering it for this as I recon it will be too easy to damage and could not be resanded to remove say a deep scratch. And it looks too good/continuous and will not match the other stuff in the room which have solid wood tops and real breadboard ends.

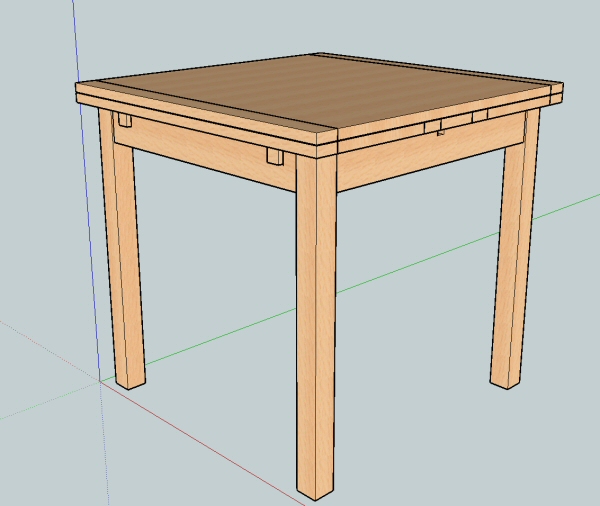

It will look something like this -

With breadboard ends on the main top and the pull out extensions. I know the problems with breadboard ends so I want to fake it rather than use solid wood.

I was thinking along the lines of resawing a planed surface off some planks down to say 5mm thick on the bandsaw then thicknessing them down to 3mm ready to stick onto 22mm MDF to give me a 25mm thick table top. The sides could be trimmed with the same or thicker and the ends could then have 'breadboards' fully glued on.

22mm MDF seems a bit hard to come by locally. 18mm would mean very thick 'veneer' is that a problem?

The other difficulty with thicknessing to 3mm is that my thicknesser stops at about 7mm so the 'veneer' would have to sit on top of a bit of say 12mm MDF to lift it up. I have done similar before on some thin strips. never tried it on something say 4" wide.

Just wondering what the best way is to go about this.

edit.

Oh and I have used bought veneered MDF before. I'm not considering it for this as I recon it will be too easy to damage and could not be resanded to remove say a deep scratch. And it looks too good/continuous and will not match the other stuff in the room which have solid wood tops and real breadboard ends.