Derek Cohen (Perth Oz)

Established Member

I was smoothing drawer bottoms with a LN #4 1/2 today and thought of this thread.

My usual preference is a #3 sized plane, however the #4 1/2 was perfect for these wide panels. This #4 1/2 is the bronze Anniversary model that LN brought out several years ago as a one-off. It came with a 50 degree frog, which was still too low then to prevent tearout in my local woods. I added a 55 degree frog .. and hated the result. The cutting angle was still too low, and the plane was very hard to push, even with a waxed sole. And so it wound up on a shelf for years.

Very recently I managed to swap the 55 degree frog for a 45 degree one. A number of years had passed and I am now more proficient in setting up a chipbreaker.

The wood is quarter sawn Tasmanian Oak, which has similar properties to White Oak, although it is a Eucalyptus.

The wonderful feature of using a chipbreaker is that you no longer have to be concerned about grain direction. In a panel it is possible to orientate the boards for best match of grain and figure, and no longer be concerned that you are planing into- or against the grain.

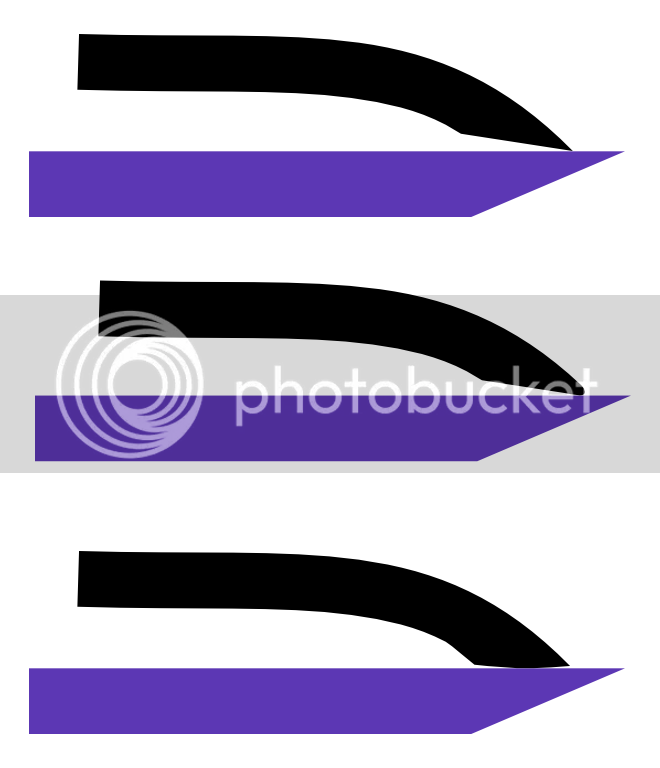

The shavings are not gossamer but that are kept thin as I do not want to lose unnecessary thickness of the panel (9mm thick) ...

Those nice, straight shaving indicate that the chipbreaker is dialled in.

The panel has a nice polished look, and the joins are not visible (three boards and two joins) ...

Regards from Perth

Derek

My usual preference is a #3 sized plane, however the #4 1/2 was perfect for these wide panels. This #4 1/2 is the bronze Anniversary model that LN brought out several years ago as a one-off. It came with a 50 degree frog, which was still too low then to prevent tearout in my local woods. I added a 55 degree frog .. and hated the result. The cutting angle was still too low, and the plane was very hard to push, even with a waxed sole. And so it wound up on a shelf for years.

Very recently I managed to swap the 55 degree frog for a 45 degree one. A number of years had passed and I am now more proficient in setting up a chipbreaker.

The wood is quarter sawn Tasmanian Oak, which has similar properties to White Oak, although it is a Eucalyptus.

The wonderful feature of using a chipbreaker is that you no longer have to be concerned about grain direction. In a panel it is possible to orientate the boards for best match of grain and figure, and no longer be concerned that you are planing into- or against the grain.

The shavings are not gossamer but that are kept thin as I do not want to lose unnecessary thickness of the panel (9mm thick) ...

Those nice, straight shaving indicate that the chipbreaker is dialled in.

The panel has a nice polished look, and the joins are not visible (three boards and two joins) ...

Regards from Perth

Derek