On a slightly different, but related topic, I thought this might be of interest...forging a samurai blade

I paid a visit to one of the last remaining professional swordsmiths in Japan who was working in the Fukushima prefecture and no, there were no signs of any devastation anywhere. We arrived to find Fujiyasu-san's assistant hammering a billet:

...of steel on the anvil. After introductions were made, I was summarily roped in to wield a hammer:

...after which both of us used the sledges to hammer the billet

It's a very complicated process, but essentially one where a very hard layer of steel is forge welded between two softer, outer layers shown in the pic, in much the same way as BB's axe clip:

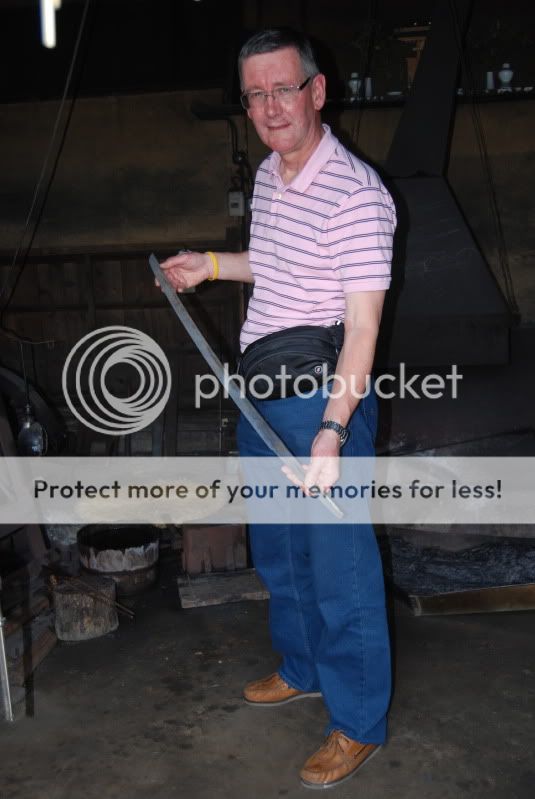

...so that after it's been repeatedly hammered to shape, the rough blade emerges:

The last process before the final forging process is to apply a slurry of charcoal and ore:

...to the blade to form the 'hamon' or decorative pattern made from super hard steel after which it's shaped on waterstones by Fujiyasu-san's assistant. After that, the blade is sent to the polisher so that when it comes back it looks like this:

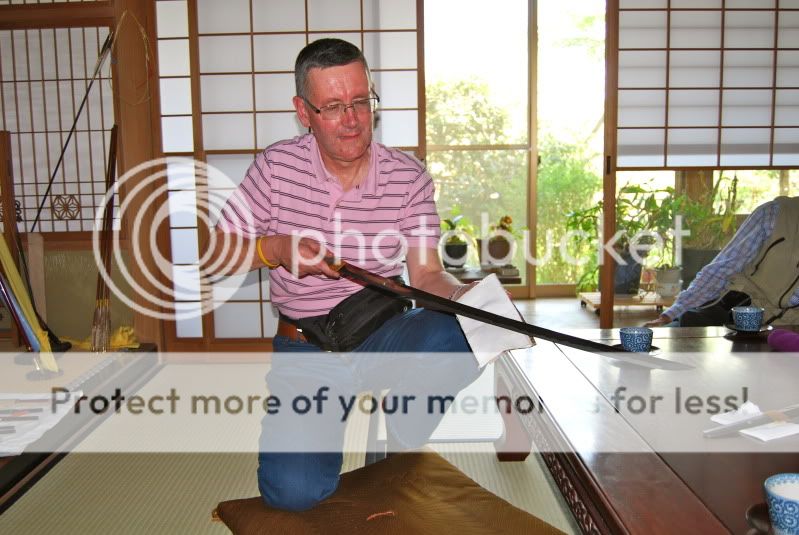

...a tanto, or short dagger and then the full sized katana:

The blade is now lethally sharp and I wasn't allowed to touch it in case finger marks developed into rust spots, so note the cotton pad in my left hand.

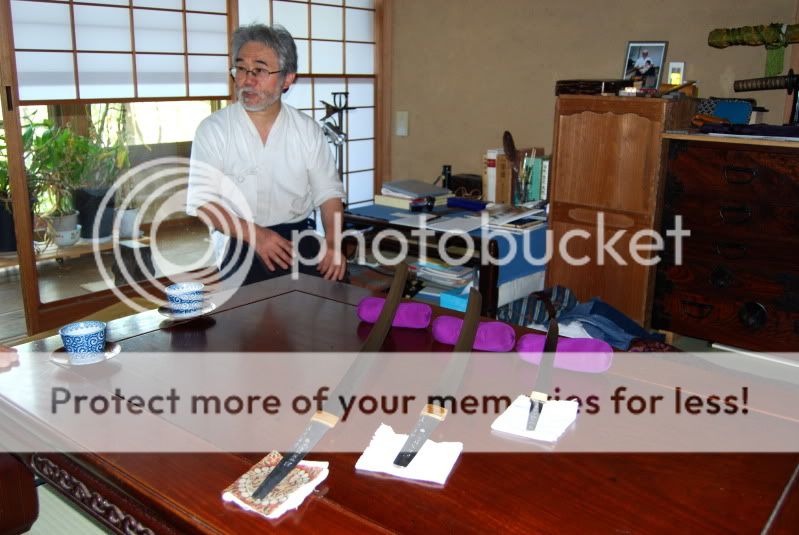

The complete set of three blades is shown below:

In case you're wondering what a completed sword is worth (and it takes two months to make one), you'd best be seated. The large, full size katana is valued at around 3,000,000JPN or roughly £30,000. However, if you have sufficient fundage in the piggy bank and would like to make a very sharp :mrgreen: :mrgreen: investment I suggest you do so now...the value of his swords may be set to double :shock: in the near future - Rob