I've been experimenting with putting a 2" tapered plane iron (the cutter only, from the double-iron for a wedged woodie) in a Bailey pattern smoother. With some filing & straightening etc, it seems to work very well - the lateral adjuster functions, but the tab on the depth adjuster won't reach through the blade (over 3.5mm thick at that point) to engage the slot in the cap iron.

So I'm back on tap-and-try depth adjustment, unless I can get a Y-lever with a much longer tab. I've tried one of the extra-long ones from Workshop Heaven, but it still won't reach on this plane. I've seen the forum thread about brazing/silver soldering an extra piece of metal on the end of the Y-lever, but I haven't got the equipment or skills for that.

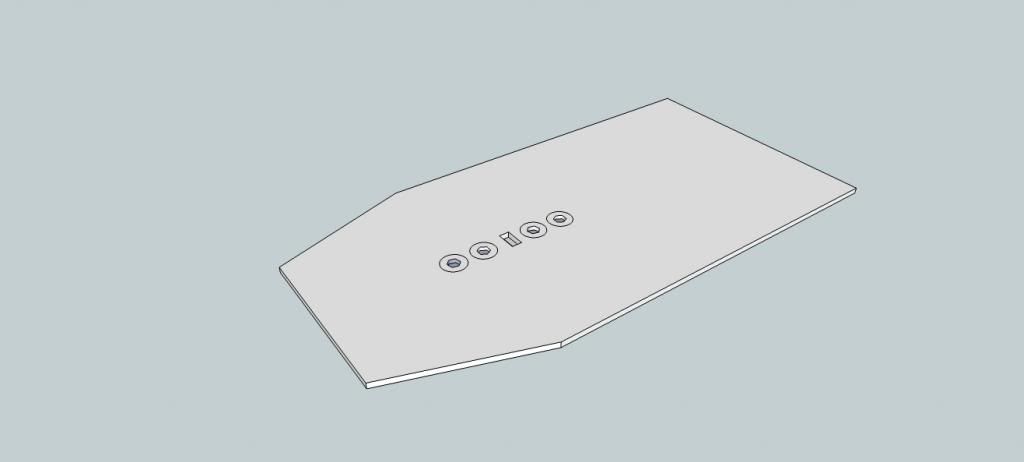

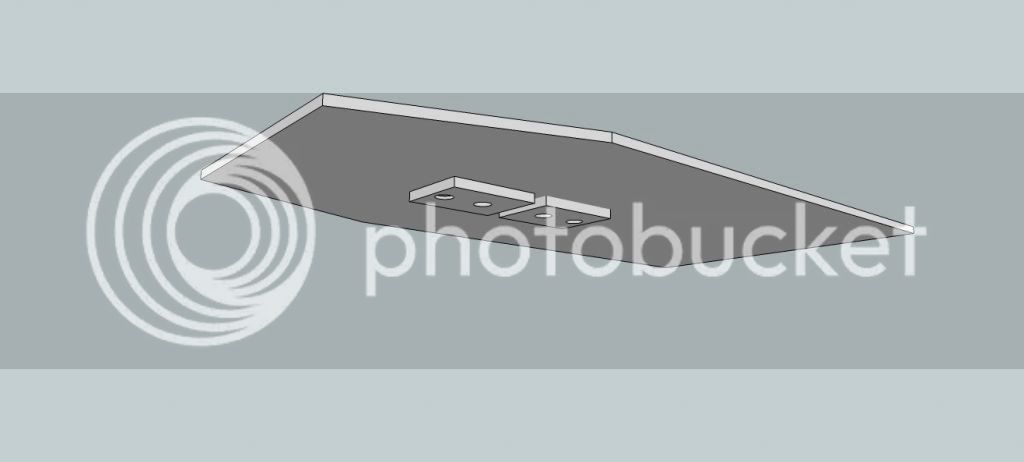

I was wondering if any of you had successfully fabricated (or attempted) a pressed-metal Y-lever? I was thinking in terms maybe of cutting two identical-shaped pieces from 2mm mild steel, bending the pieces outwards at the lower end to form the yoke, gluing the pieces together at the upper (tab) end with epoxy, pop-riveting at the pivot point and re-drilling the centre of the rivet to form the pivot hole.

Do you think such an assembly would withstand the forces involved? It would take a bit of effort to make, so I'd rather not bother if the general opinion is that it won't work anyway!

Or does anyone have any other bright ideas for how I can solve my problem (not involving silver-soldering)?

So I'm back on tap-and-try depth adjustment, unless I can get a Y-lever with a much longer tab. I've tried one of the extra-long ones from Workshop Heaven, but it still won't reach on this plane. I've seen the forum thread about brazing/silver soldering an extra piece of metal on the end of the Y-lever, but I haven't got the equipment or skills for that.

I was wondering if any of you had successfully fabricated (or attempted) a pressed-metal Y-lever? I was thinking in terms maybe of cutting two identical-shaped pieces from 2mm mild steel, bending the pieces outwards at the lower end to form the yoke, gluing the pieces together at the upper (tab) end with epoxy, pop-riveting at the pivot point and re-drilling the centre of the rivet to form the pivot hole.

Do you think such an assembly would withstand the forces involved? It would take a bit of effort to make, so I'd rather not bother if the general opinion is that it won't work anyway!

Or does anyone have any other bright ideas for how I can solve my problem (not involving silver-soldering)?