- Joined

- 19 Mar 2007

- Messages

- 5,288

- Reaction score

- 364

As some of you know, I'm always up for a challenge and earlier I had posted some photos of what called inside out turning. Too long to explain here, better to do a e=search on it if you haven't heard of it before.

Well, I have made a 4 section followed by a 3 section jobbie which turned out a lot better IMHO. But, I thought 'I wonder if it's possible to do an 8?' So armed with a lump of beach wood, about 8" long by 4" square I sawed it lengthwise in to 8 segmenta, like an orange, turned them inside out and glued them back together. Turned a waste like form inot it. Then split them back into the 8 bits and turned them back the original way. That gave me the same internal form as a 4 bit, so I rearranged them the right way out but in a different form and glued them back together again. This time as a permanent fixture.

Back onto the lathe and turned the outside to the shape I wanted, heart in mouth and ready to duck toot-sweet (as the French would say?) No bits flew off and it took the shape I wanted.

I wanted it to be a candle stick to take one of my 3" spherical candles so a curve was shaped in the top. I finished up with

8 bit inside out 2 by John, on Flickr

8 bit inside out 2 by John, on Flickr

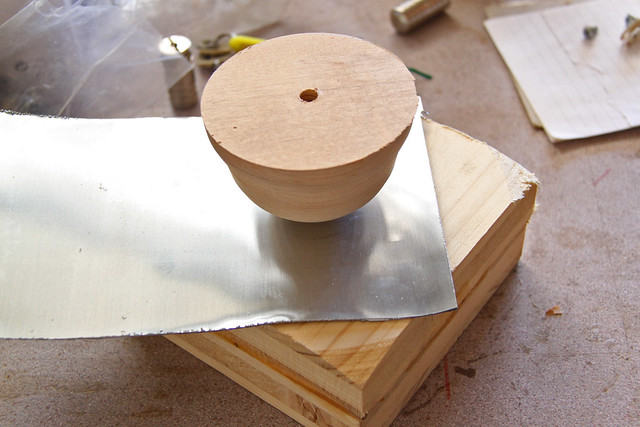

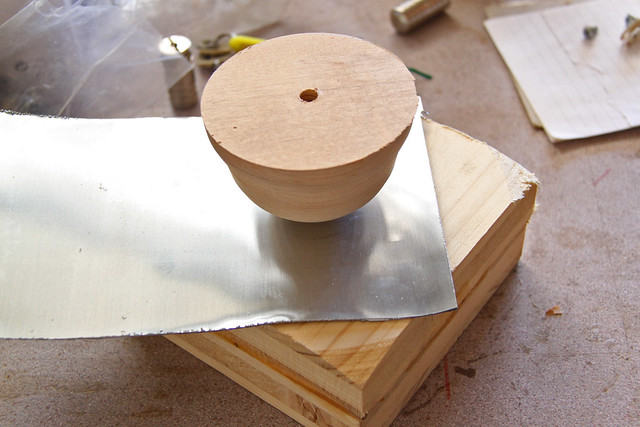

I didn't want the candle just to sit in the dip in the bare wood. I have some zinc drain piping left over from fitting some rain water tubs. The zinc is a nice silvery, shink, soft metal, so i wondered??? So I opened up a bit of it. It's only soft soldered, and cut about a 5" square

I turned a press for it

8 bit candle stick zinc 1 by John, on Flickr

8 bit candle stick zinc 1 by John, on Flickr

8 bit candle stick zinc 2 by John, on Flickr

8 bit candle stick zinc 2 by John, on Flickr

And employed my 6 tonne log splitter

to put a bit of pressure on it, as you do?

to put a bit of pressure on it, as you do?

8 bit candle stick zinc 3 by John, on Flickr

8 bit candle stick zinc 3 by John, on Flickr

And finished up with what looked like a floded silver handkerchief

8 bit candle stick zinc 5 by John, on Flickr

8 bit candle stick zinc 5 by John, on Flickr

It fitted beautifully into the dip

8 bit inside out 3 by John, on Flickr

8 bit inside out 3 by John, on Flickr

And the candle fitted as if it had been made for the job

8 bit inside out 4 by John, on Flickr

8 bit inside out 4 by John, on Flickr

I still have to give it a coat of herd wax oil and polish, but all in all, I like it and it is very different. The holes are alternate high/low as I turned the even segments upside down to get the effect I hoped for. That is why it isn't as good a join as I would have liked in places?

C'est la vie..

Well, I have made a 4 section followed by a 3 section jobbie which turned out a lot better IMHO. But, I thought 'I wonder if it's possible to do an 8?' So armed with a lump of beach wood, about 8" long by 4" square I sawed it lengthwise in to 8 segmenta, like an orange, turned them inside out and glued them back together. Turned a waste like form inot it. Then split them back into the 8 bits and turned them back the original way. That gave me the same internal form as a 4 bit, so I rearranged them the right way out but in a different form and glued them back together again. This time as a permanent fixture.

Back onto the lathe and turned the outside to the shape I wanted, heart in mouth and ready to duck toot-sweet (as the French would say?) No bits flew off and it took the shape I wanted.

I wanted it to be a candle stick to take one of my 3" spherical candles so a curve was shaped in the top. I finished up with

8 bit inside out 2 by John, on Flickr

8 bit inside out 2 by John, on FlickrI didn't want the candle just to sit in the dip in the bare wood. I have some zinc drain piping left over from fitting some rain water tubs. The zinc is a nice silvery, shink, soft metal, so i wondered??? So I opened up a bit of it. It's only soft soldered, and cut about a 5" square

I turned a press for it

8 bit candle stick zinc 1 by John, on Flickr

8 bit candle stick zinc 1 by John, on Flickr 8 bit candle stick zinc 2 by John, on Flickr

8 bit candle stick zinc 2 by John, on FlickrAnd employed my 6 tonne log splitter

8 bit candle stick zinc 3 by John, on Flickr

8 bit candle stick zinc 3 by John, on FlickrAnd finished up with what looked like a floded silver handkerchief

8 bit candle stick zinc 5 by John, on Flickr

8 bit candle stick zinc 5 by John, on FlickrIt fitted beautifully into the dip

8 bit inside out 3 by John, on Flickr

8 bit inside out 3 by John, on FlickrAnd the candle fitted as if it had been made for the job

8 bit inside out 4 by John, on Flickr

8 bit inside out 4 by John, on FlickrI still have to give it a coat of herd wax oil and polish, but all in all, I like it and it is very different. The holes are alternate high/low as I turned the even segments upside down to get the effect I hoped for. That is why it isn't as good a join as I would have liked in places?

C'est la vie..