Dalboy

Established Member

I make toys as well as spending my time turning. One of the things that I need are spoked wheels of different sizes some of which I can do on the lathe. Well this jig makes setting up to drill holes in the centre hub a lot easier and less time consuming.

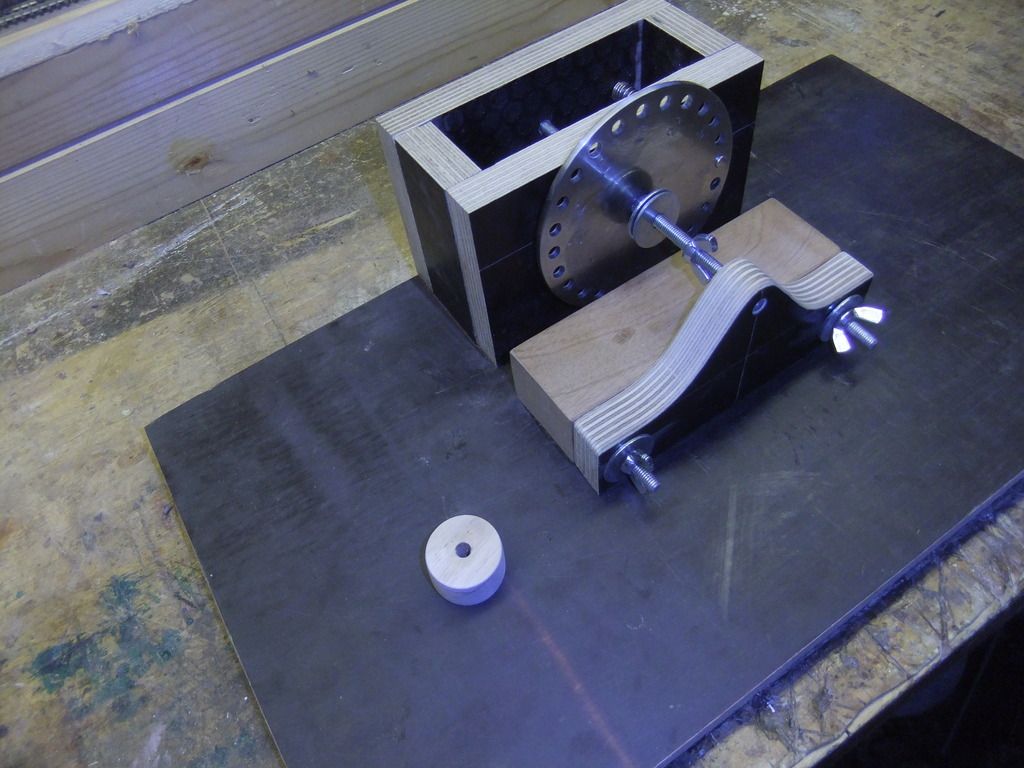

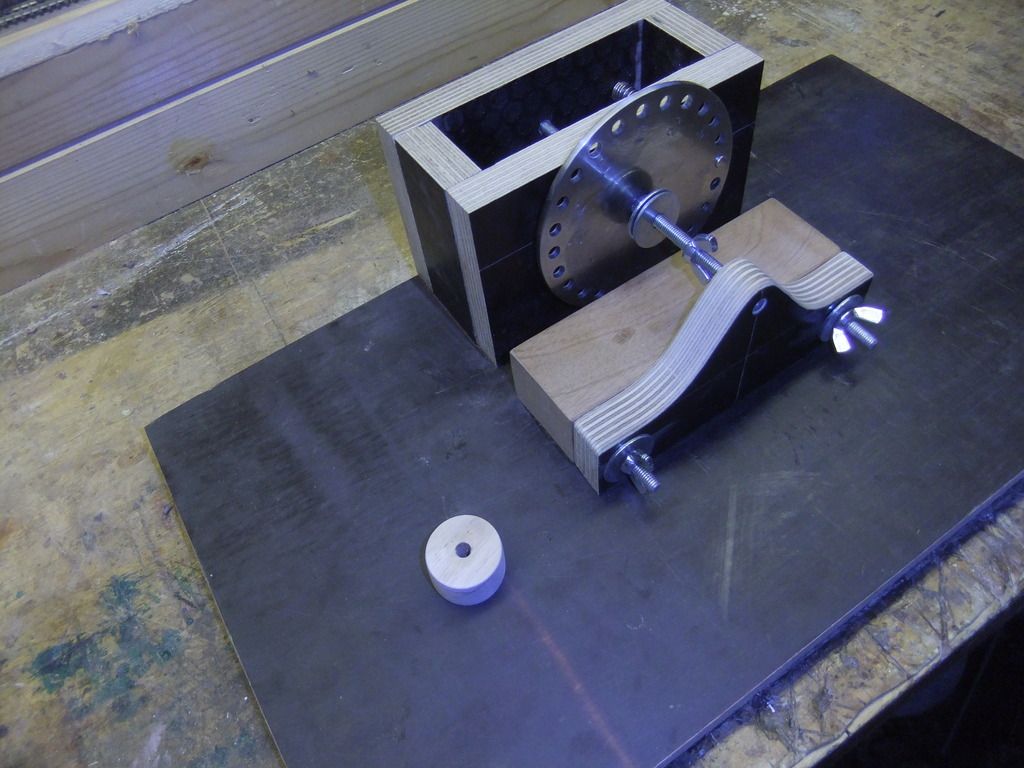

Blank ready for attaching

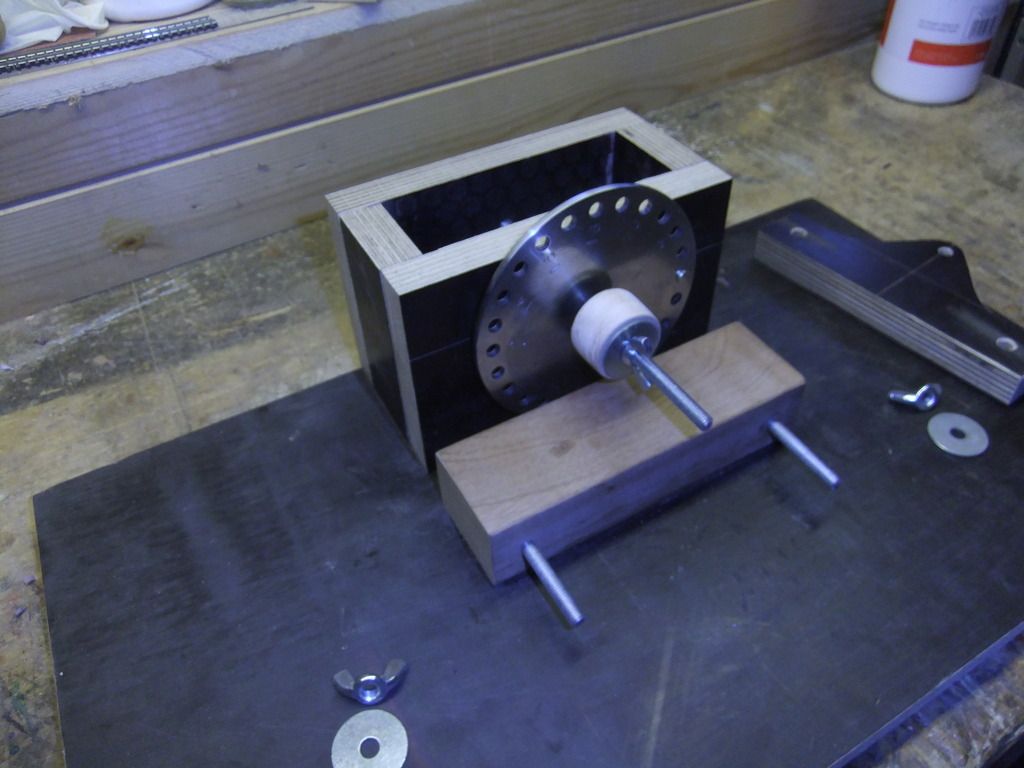

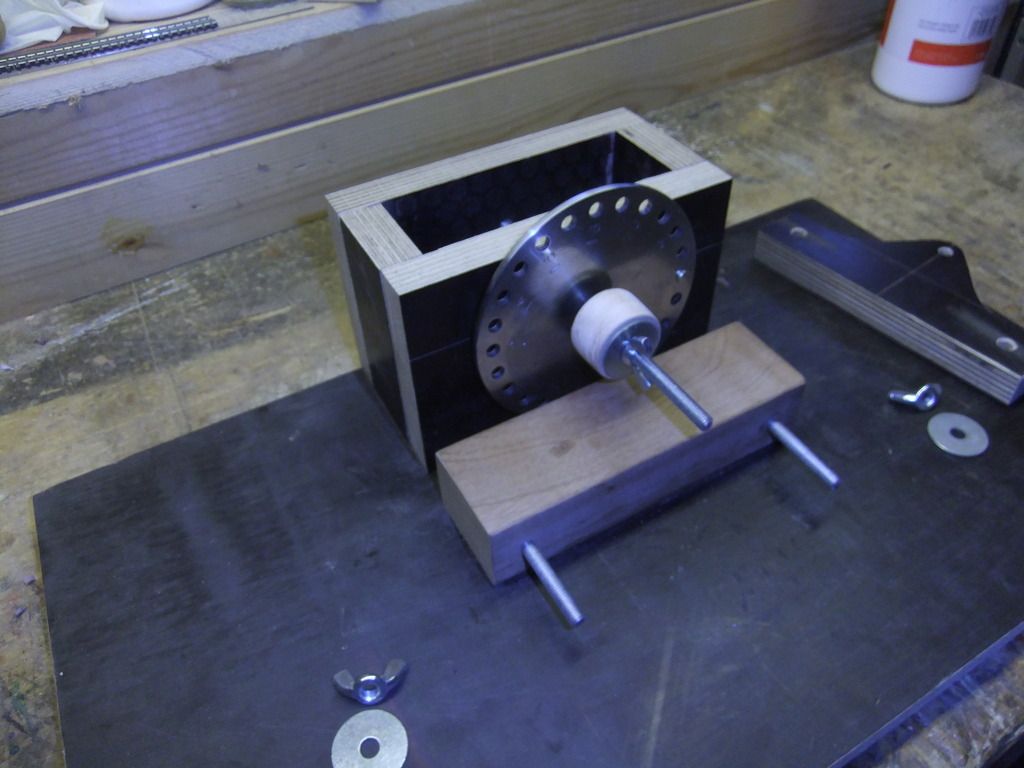

How the blank is mounted

Mounted and ready to drill

The end result with a rubbish piece of wood still a happy result this took less than 5 minutes from cutting the blank to all the holes drilled

Blank ready for attaching

How the blank is mounted

Mounted and ready to drill

The end result with a rubbish piece of wood still a happy result this took less than 5 minutes from cutting the blank to all the holes drilled