manxnorton

Established Member

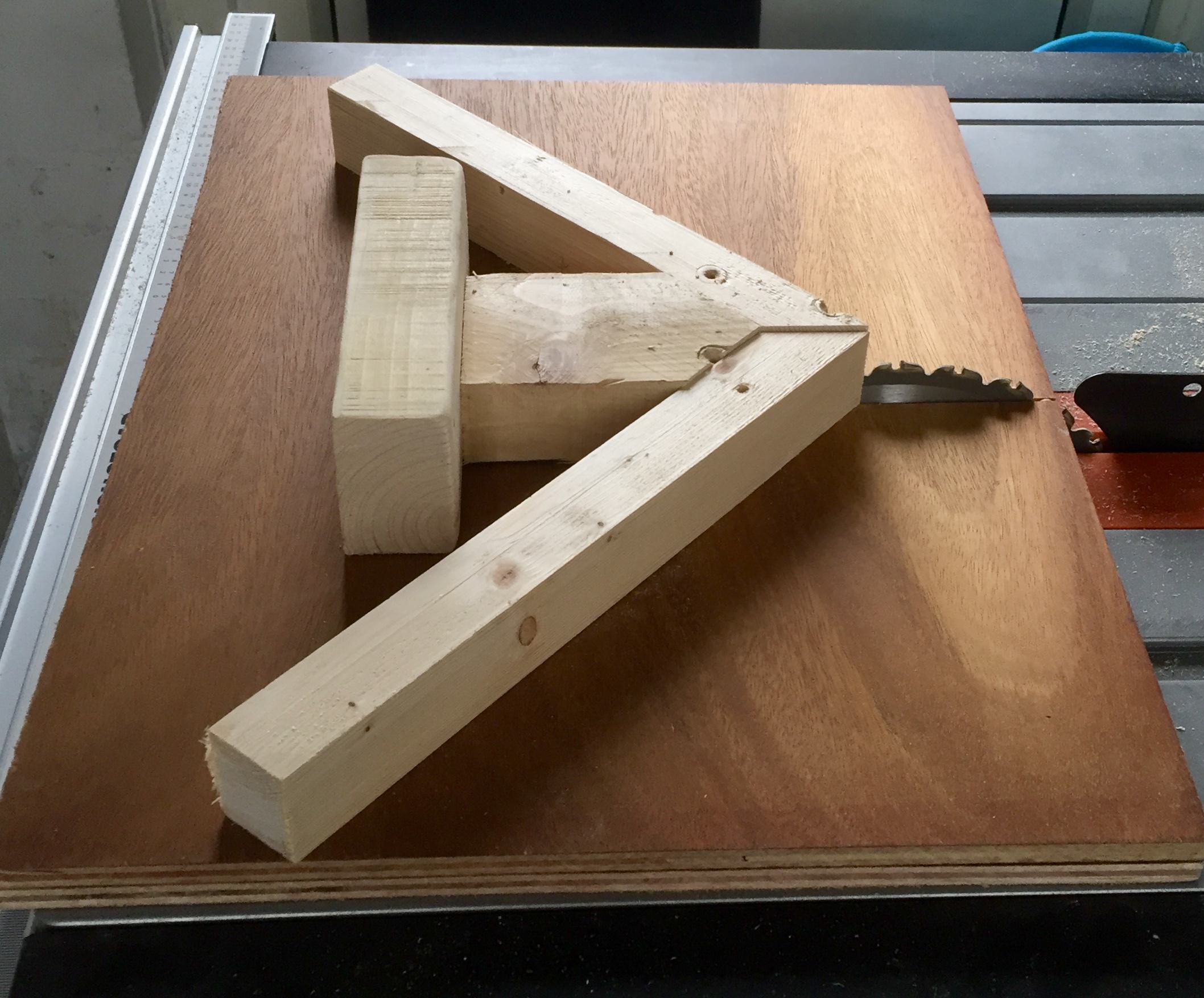

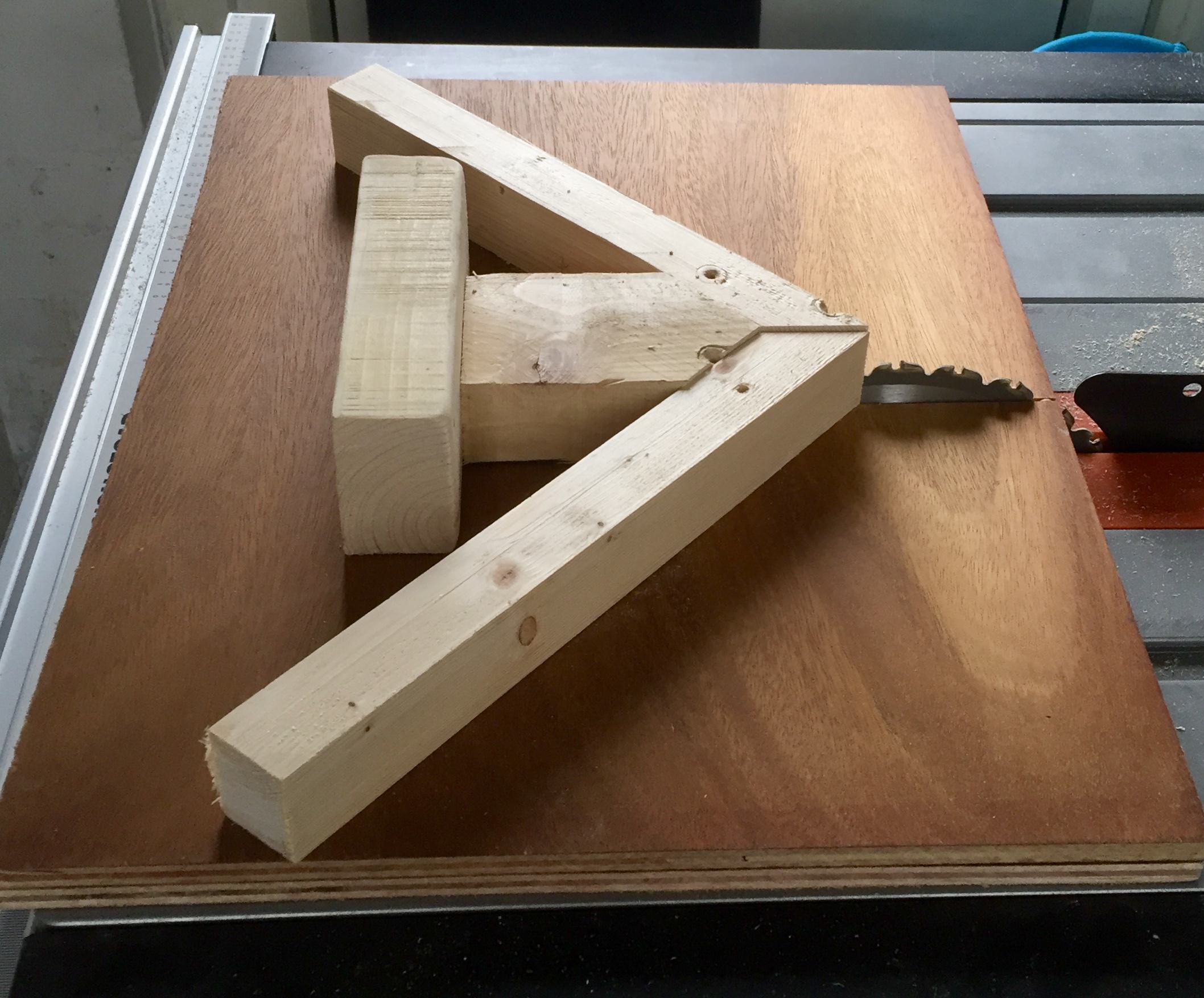

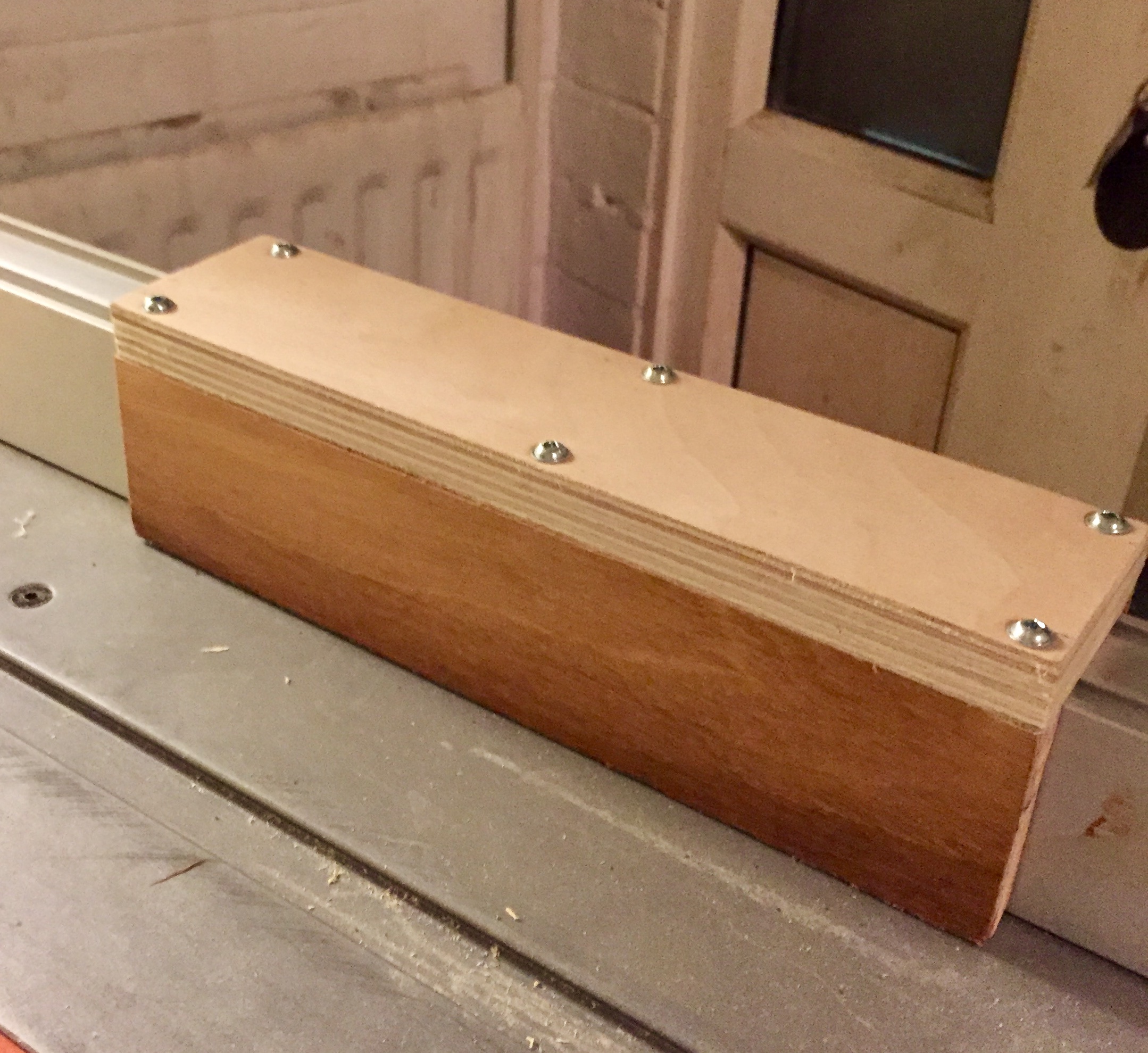

As I mentioned early on in my project thread, I spied the making of possible spline jig.

As this was initialy for picture frames, and never gets used.

So easy to dismantle things and rip for measures as its was screwed not glued.

With a bit of fwd thinking (me thinking!!! :lol: :lol: ) it started to look like this.

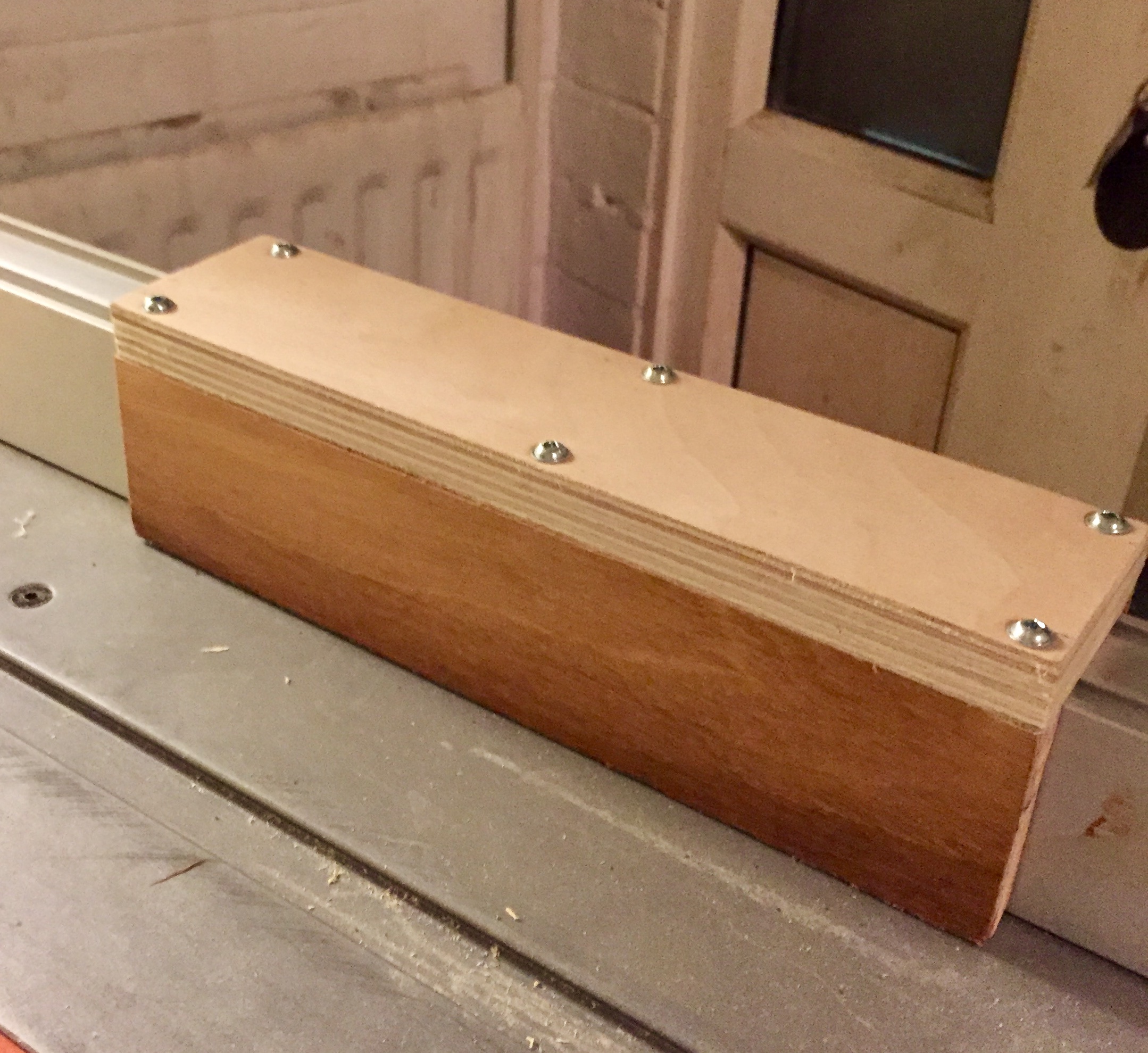

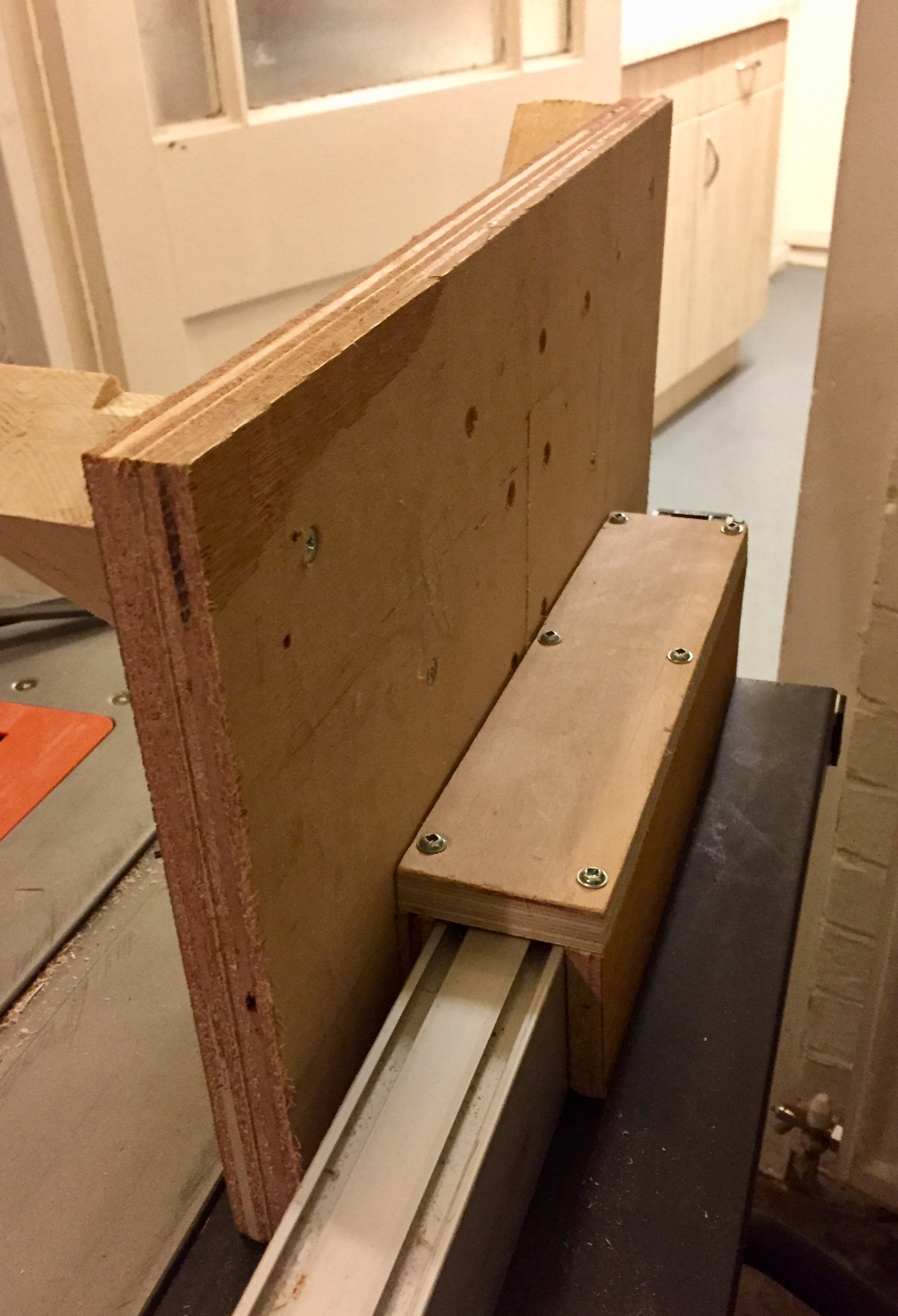

So with the spare plywood got to fashion a guide for the rip fence.

a great fit, and I put some wax to help aswell.

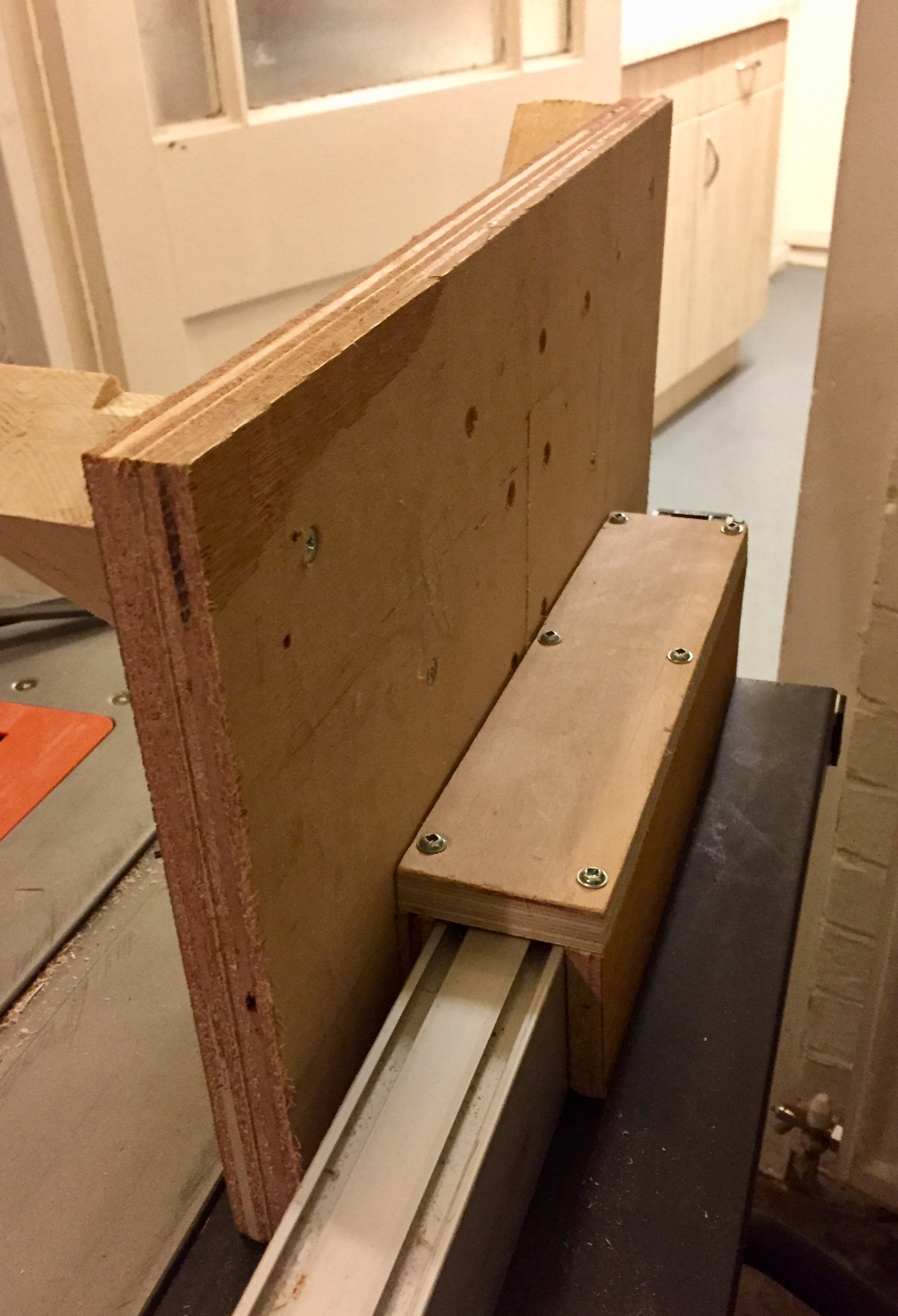

Apart from securing the box and final sanding and sealing it, works really well.

Got some hard wood stips left over.

Pull saw to flush it.

All I need to do today (if I have time, as our lass is off today :shock: )

)

Thank for viewing.Bri

As this was initialy for picture frames, and never gets used.

So easy to dismantle things and rip for measures as its was screwed not glued.

With a bit of fwd thinking (me thinking!!! :lol: :lol: ) it started to look like this.

So with the spare plywood got to fashion a guide for the rip fence.

a great fit, and I put some wax to help aswell.

Apart from securing the box and final sanding and sealing it, works really well.

Got some hard wood stips left over.

Pull saw to flush it.

All I need to do today (if I have time, as our lass is off today :shock:

Thank for viewing.Bri