Gary S

Established Member

Morning all,

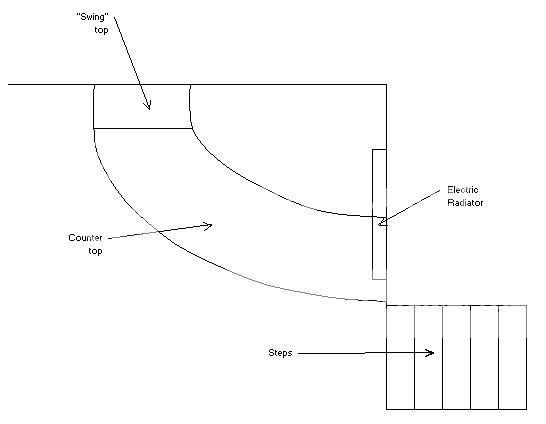

I've been commissioned (well, asked nicely!) to build a "Nail Bar" for a friend who's opening up her own hairdressing salon. Essentially a Nail Bar is like a raised desk that has a beautician on one side and one / two clients on the other having their nails done. (Just in case you don't know what one is...!).

It is going to be a curved counter top which needs to be white and quite tough / easy to clean. Any suggestions for the best type of material to use? I'm a bit stuck: a kitchen worktop won't be the correct size and would probably look a bit naff. Using 2 sheets of 18mm MDF glued together would work, but then how could I get a great finish that is also strong enough to take daily use?

The base needs to be curved in the same way as the counter top - I was thinking of building a framework and using 'bendy MDF' around it. Finishing this is easier because it doesn't need to be as tough and durable as the counter top.

Now beginning to wish I hadn't agreed to help...!!

Quick rough sketch is shown below in case my description wasn't good enough.

Any advice or suggestions will be gratefull received (unless the advice is "Don't do it"!!).

Cheers

Gary

(Just wondering why I added the steps to the diagram...?!)

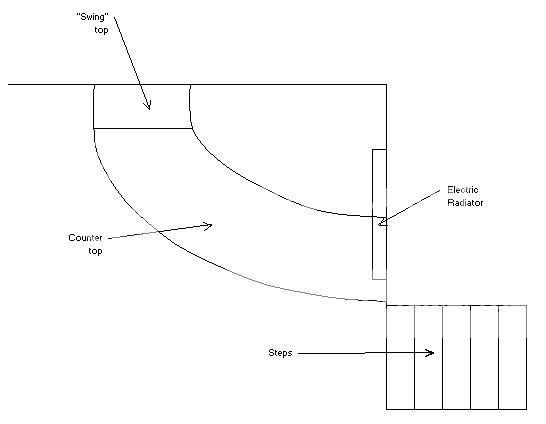

I've been commissioned (well, asked nicely!) to build a "Nail Bar" for a friend who's opening up her own hairdressing salon. Essentially a Nail Bar is like a raised desk that has a beautician on one side and one / two clients on the other having their nails done. (Just in case you don't know what one is...!).

It is going to be a curved counter top which needs to be white and quite tough / easy to clean. Any suggestions for the best type of material to use? I'm a bit stuck: a kitchen worktop won't be the correct size and would probably look a bit naff. Using 2 sheets of 18mm MDF glued together would work, but then how could I get a great finish that is also strong enough to take daily use?

The base needs to be curved in the same way as the counter top - I was thinking of building a framework and using 'bendy MDF' around it. Finishing this is easier because it doesn't need to be as tough and durable as the counter top.

Now beginning to wish I hadn't agreed to help...!!

Quick rough sketch is shown below in case my description wasn't good enough.

Any advice or suggestions will be gratefull received (unless the advice is "Don't do it"!!).

Cheers

Gary

(Just wondering why I added the steps to the diagram...?!)