wallace

Established Member

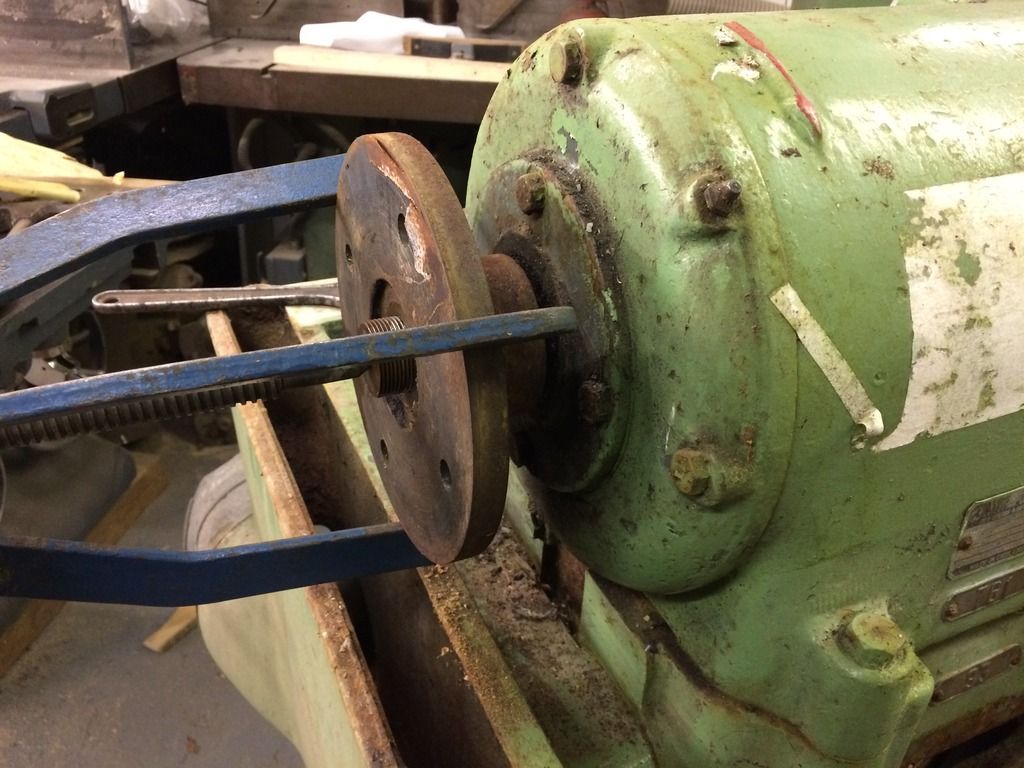

Here we go again folks. You don't realise how big these machines are until your next to one. This is in pretty bad condition.

Everything is heavy so a block and tackle is needed

The electrics were 'modernised' maybe 30 years ago presumably when it got its lovely coat of green paint.

The hinges snapped when I opened the electric panel, that's the first time I've had that happen so I think this has stood outside for quite a while.

Everything is heavy so a block and tackle is needed

The electrics were 'modernised' maybe 30 years ago presumably when it got its lovely coat of green paint.

The hinges snapped when I opened the electric panel, that's the first time I've had that happen so I think this has stood outside for quite a while.