Greetings all, I have just bought an old wadkin ber2 spindle. It doesn"t have a cutter block. I want to cut tenons from mostly 44mm stock with it. Can anybody advise the best set-up for this procedure?

Many thanks BECKS :?:

Many thanks BECKS :?:

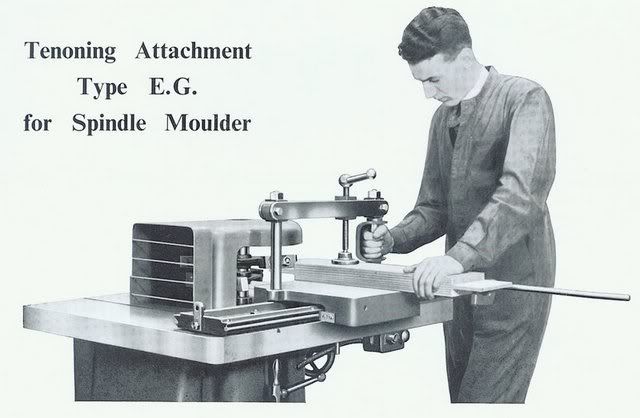

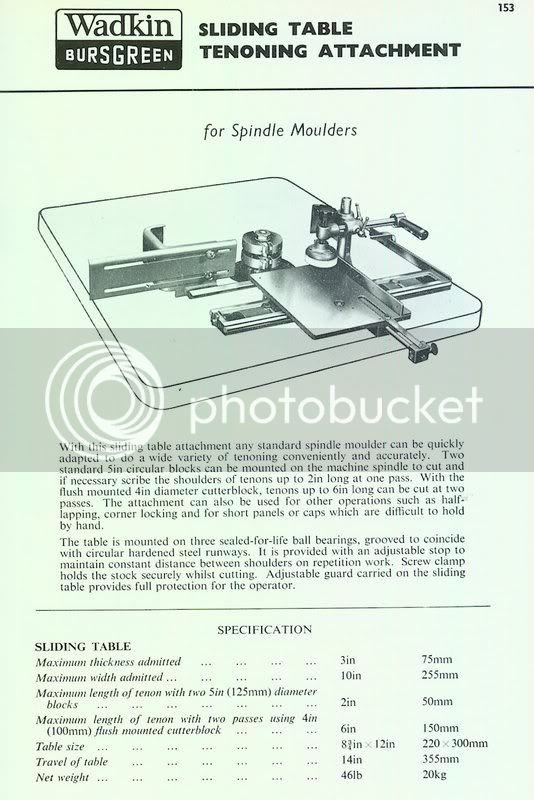

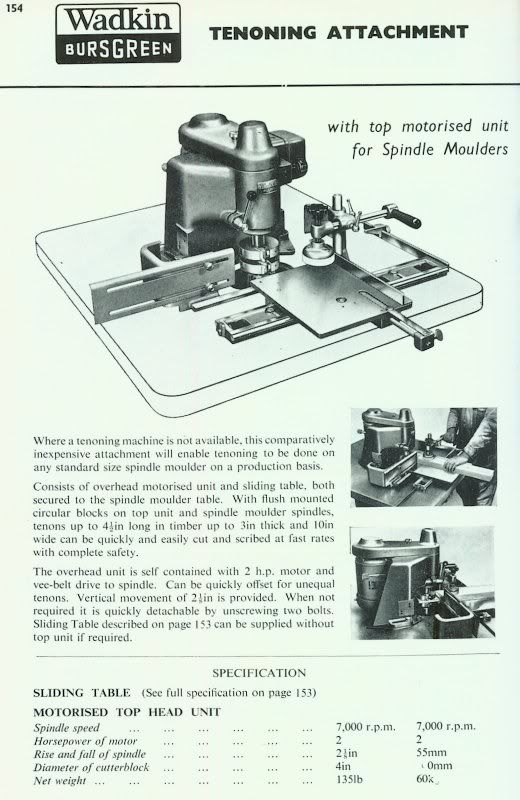

Hi BecksFelderMan":21ifw36s said:Do you have the tennoning hood for the machine ?.

Just depends how enamoured you are of working with unguarded sawblades and an unstable vertical stick of timber.....Shivers":2q6m6zif said:You can do the same thing in a tablesaw using a jig too.

Scrit":1g9n626p said:Hi Becks

Maybe FelderMan can confirm this.

Scrit

Enter your email address to join: