Finally sorted out the #4 restoration images...

Just like last time, the blade, cap iron and screws had a bath:

Less than 24 hours later there was lots of bubbling:

A quick wipe with steel wool, bicarb bath, oven drying and oiling later they looked good. I cleaned then flattened the sole and de-rusted the frog as I did with the #4 1/2. I don't think this one was used much either, as the japaning is in good order (the items on the left of the shot are a Record #3):

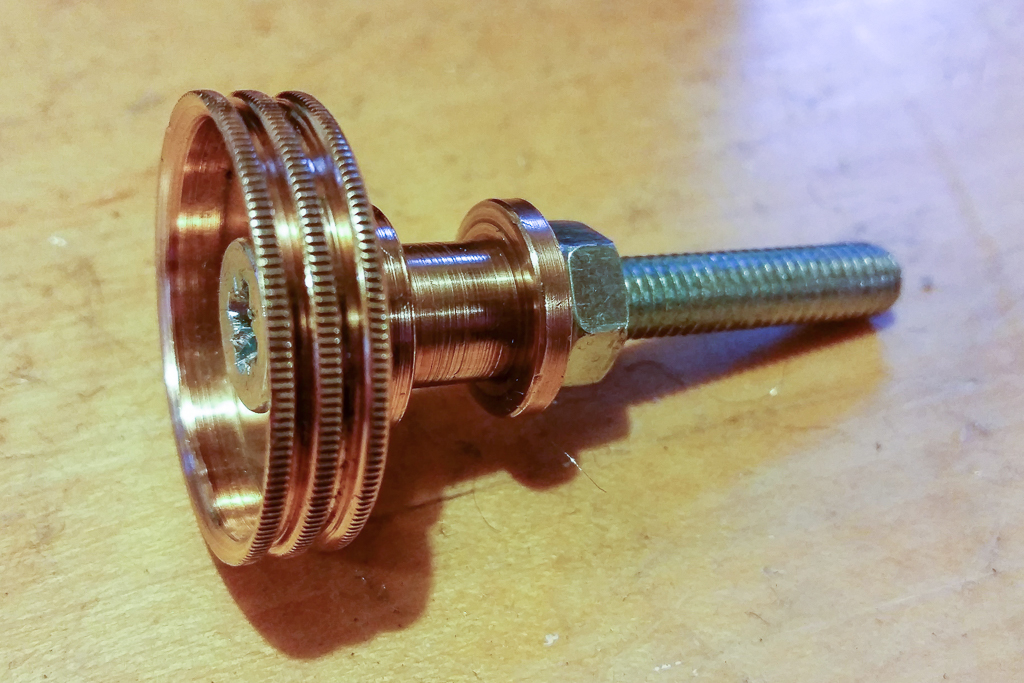

I usually put the screws in the jaws of a drill driver to spin them for easy cleaning with wire wool, but the brass depth adjustment nut is too large. Then it occurred to me - use an M6 bolt. Really easy to get it shiny:

Finally, here are a set of before/after shots:

The marks on the frog face appear to be pitting from casting, as I'm pretty certain the dark marks are actually japaning rather than rust.

I have a separate new handles + restoration project on-going, so the handles will be replaced some time soon.