phil.p":2ltxjlmg said:

I suspect VHS was no different then than Windows is now. It was ubiquitous because it hit the market at the right time, not because it was better than anything else.

It was ubiquitous because Sony decided to make Betamax tapes small and thus shorter, even though it held almost 100% of the market to begin with. VHS, however, could be left to record a full length film - Duration was more important to people, which is why they usually opted for Long Play mode and forewent the higher quality picture option in favour of recording more programmes on the one cassette.

TechSpecs-wise, there wasn't much perceptible difference, if any.

Jacob":2ltxjlmg said:

Mr Ford was a retired joiner in 1982 which would have made him 60 ish. He almost certainly would have trained before and around 1940 when the great tradition of woodwork was still going strong.

So the old ways are the only ways and there's only ever one way to skin a cat, yes?

Jacob":2ltxjlmg said:

Jeer as much as you like - but in fact his method is very effective and was probably absolutely standard and was taught via C&G courses, which were derived from trade practices - not from would-be amateur woodwork gurus in sheds with video cameras!

And woodworking gurus in sheds (as well as being paid instructors, and actual workers who make stuff for money) were many years in the trade themselves, starting as apprentices taught by those with many years in the trade as well... doesn't mean one is better than the other, does it?

Or should I now be chopping every motice on my fine, delicate woodwork witha hoofing great mortise chisel a-la the Mister Ford method?

If he's still alive, I may go see what the Mr Crozier method was, just for giggles...!

phil.p":2ltxjlmg said:

Modern? the flat side was the back when I was at school 50 years ago - I never heard anyone call it the face til I read it here.

Simple way around it - Flat side and bevel side.

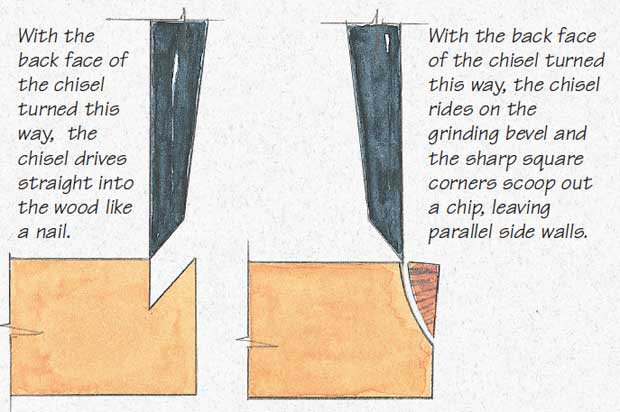

Have the flat side vertical and facing the 'knife wall as you work away from it, riding the bevel down as you chisel out.