Sorry guys...I've been rather busy of late with various projects I'm working on to cope with replacing the physical tasks I currently do such as hacksawing as it is getting more and more difficult to do these things healthwise.

So...where did we leave it...oh yes...the PID and the decarburisation issues.

Well...since I was unable to locate a suitable supply of stainless foil without remortgaging the house...I went for the dirty route...quite literally!!!

Ok!!! I'm never gonna make a potter so Clarice Cliff can rest easy in her grave....but it was all worth it in the end...read on!

This concoction which can only be described as "MUD" is seen drying here after a couple of slight "errors" on my part....not the least of which is that I am now the proud owner of most of the country's fire clay supply!!

This stuff is so cheap that when I ordered some on eBay...I didn't look at the quantity and it was only when the truck pulled up at my house with a hoist did I realise that £20 get you an AWFUL LOT of the stuff. So anyone who wants a bag...feel free to just pay me the postage!! :mrgreen:

Quite the opposite occurred with the Borax...where I seem to have bought the purest scientific version of DAZ I could find!

But...never mind...the worst thing was convincing Annie that all this was in the aid of science and I needed to use the kitchen as I was just making a very special cake!! :? 8)

So...to the PID or "accurate temperature control thingy" to make it more understandable....

Well give the Chinese their due..they make some cunning electrickery for very few dollars...it was amazingly easy to tune...not too much fiddling with the "d" variable thankfully...and it taught itself what 800 degrees celsius was and stayed there.

It stayed there within ONE DEGREE either side...so you can't wish for better than that. And the solid state relay (SSR) didn't even blink. Well...actually it DID blink...quite a bit...as it switched on and off frantically trying to keep up with the commands it was being sent but it performed effortlessly! So much so that I am building this into a box with a socket to keep my heater accurate for when I'm not using the kiln. I am actually considering using the kiln AS the heater...such was the toastiness of the workshop during and for many hours, AFTER this hardening malarky! :mrgreen:

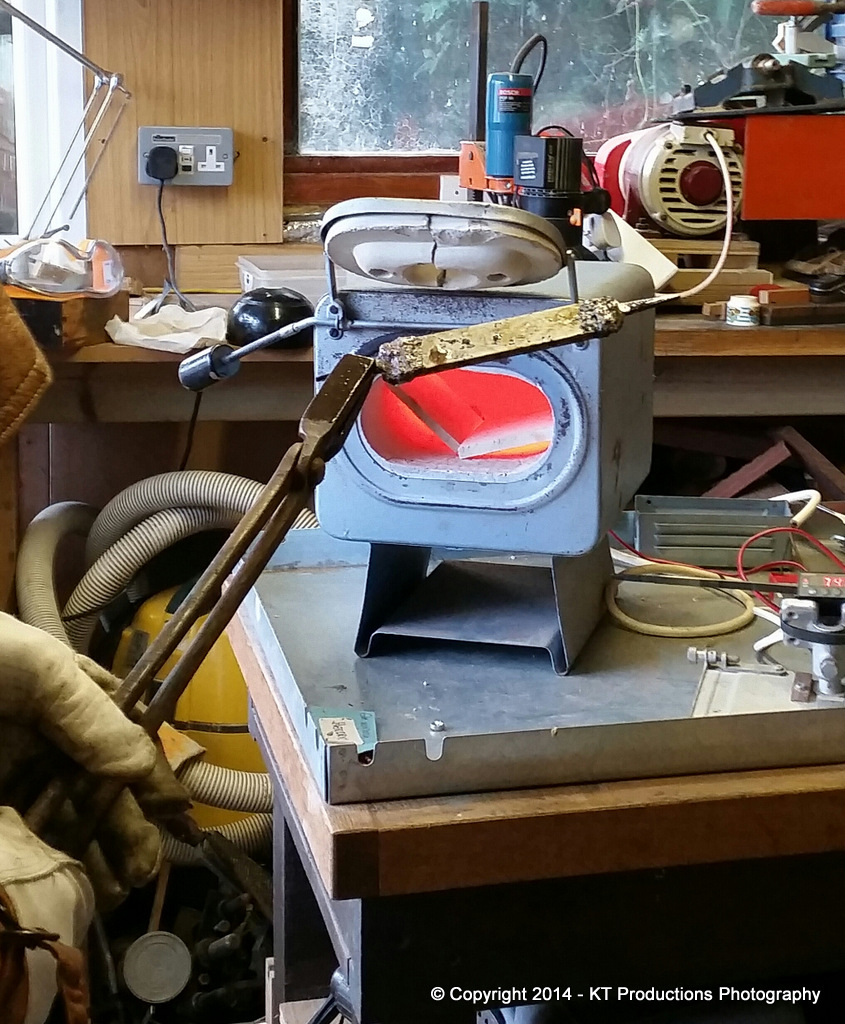

Armed with this total confidence temperature-wise....I popped the "cake" into the oven...(gas mark 10 for 15 minutes!)....

...where upon...in very short shrift...the fire clay lived up to it's name and looked like Hades itself! :mrgreen:

After 15 minutes of cooking...I opened the door to the kiln...suitably attired in my "DIY PPE" which protected any part of my body I should have preferred not to be singed.....and with Annie standing by with a fire extinguisher...dunked it in the vegetable oil.

I have to say...since the last time I did this my recollection of the reaction of plunging a lump of steel at nigh on 1000 degrees into cold liquid was not quite as vivid as this attempt!! :shock:

I guess the fire clay made it more....um...explosive!!

This "after" shot makes it look as if I'm calm...this is because it was a little after the "missing" picture. Missing because Annie was frantically trying to remember how to get the seal off the fire extinguisher!!! :mrgreen:

Ok...it wasn't quite "dangerous" but it was...um...surprising. The fire clay doesn't like being subjected to that much shock so it left the steel it was adhering to...with a bit of...shall we say...kinetic energy! :lol:

Which was handy because it saved me from chipping it all off afterwards...the only bits left were the ones the reinforcement of the wires....

But was all this preparation a success though!? Darn right it was! 8)

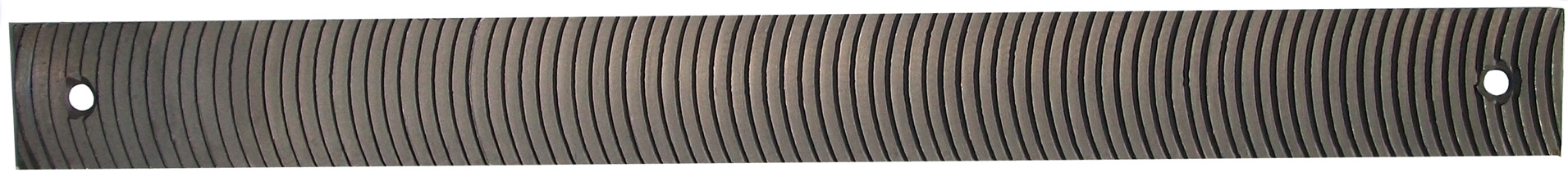

As can be seen...no warpage (?)....no separation of the wires...and no decarburization!! Success indeed! :wink:

Armed with this renewed confidence I then made my mistake. Instead of calmly cleaning off the oil and tempering it....I put it back in the kiln...at the prescribed higher tempering temperature and shut the door.

Ordinarily for plane irons I would shove it in the domestic oven after the family roast...which is off and cooling. This...is BELOW the flashpoint of vegetable oil.

UNFORTUNATELY.....500C ISN'T! :shock:

By this time...Annie had retired scratching her head...to the house...and taking the fire extinguisher with her!!

I will say that blowing on flaming steel frantically does eventually work however! #-o

Sadly...burnt vegetable oil on metal...as every housewife knows..stains rather badly...

.....which is rather a shame...but they are prototypes and these things happen!

So to the long awaited testing.

I grabbed the nearest spare handle I could find which I just knew I had a use for when I made it all those years ago from some scrap lilac from MAC Timbers.

...bit of beech...clamped to my new bench (more on that later!)....and off we go...

SUCCESS!!! :mrgreen:

Then on to a "bit of boxwood"....(close your eyes if you don't like to see rare breeds being sacrificed in the name of science!!!)....

Success again. (you may get the impression here that I am just a tad pleased after all this "theory"!!)

The great thing is you can hog the stock off really fast but if you lay off the pressure to a gently stroking action...the surface (left in the above picture) becomes really smooth.

So...I guess I ought to sharpen it!! :mrgreen:

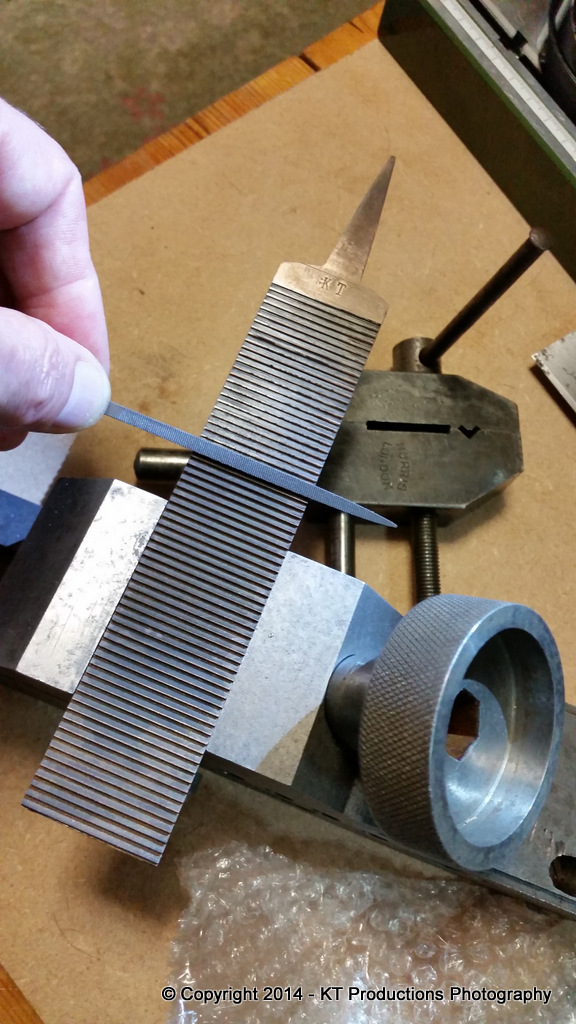

Using Switzerland's "nearly finest (without going overdrawn) steel....a BAHCO "SWISS MADE" (as opposed to no name "SWISS CHEESE") three-square needle file...

...I set about the job in the same way as you would tickle a saw...for effectively that is what a float is...a rather large kerfed "saw".

Technical note here...I don't actually file like this...but I had to hold the camera with the other hand! :mrgreen:

After a surprisingly short time (one episode of "Murder She Wrote")....it was done....

So...now to test the real thing....did it work?

...hell yes....and this is across the grain English boxwood!

I'm rather glad that Toby "coerced" me into making one of these things and I've ordered one of Matthew's finest Holtzapffel style handles just to celebrate! 8)

To say that it's been a "learning experience" is probably an understatement. I had to scrape to the bottom of the grey cells to remember metalwork, metallurgy, chemistry, electronics, woodworking and bravery....not to mention testing of sanity but it was fun.

Would I do it again...

NO! But feel free to copy or avoid any of this experience at your leisure!

Now...Toby...your findings? :wink:

Cheers

Jimi

DISCLAIMER: THERE ARE POTENTIALLY DANGEROUS TECHNIQUES INVOLVED IN THIS PROJECT WHICH COULD RESULT IN INJURY. DO NOT TRY ANYTHING I HAVE DESCRIBED UNLESS YOU ARE TOTALLY CONFIDENT YOU CAN DO SO SAFELY OR ARE CLINICALLY INSANE. REMEMBER...THERE IS NO MORE IMPORTANT SAFETY ITEMS THAN WEARING SAFETY GLASSES! CONSIDER YOURSELF WELL AND TRULY WARNED!!