Hello,

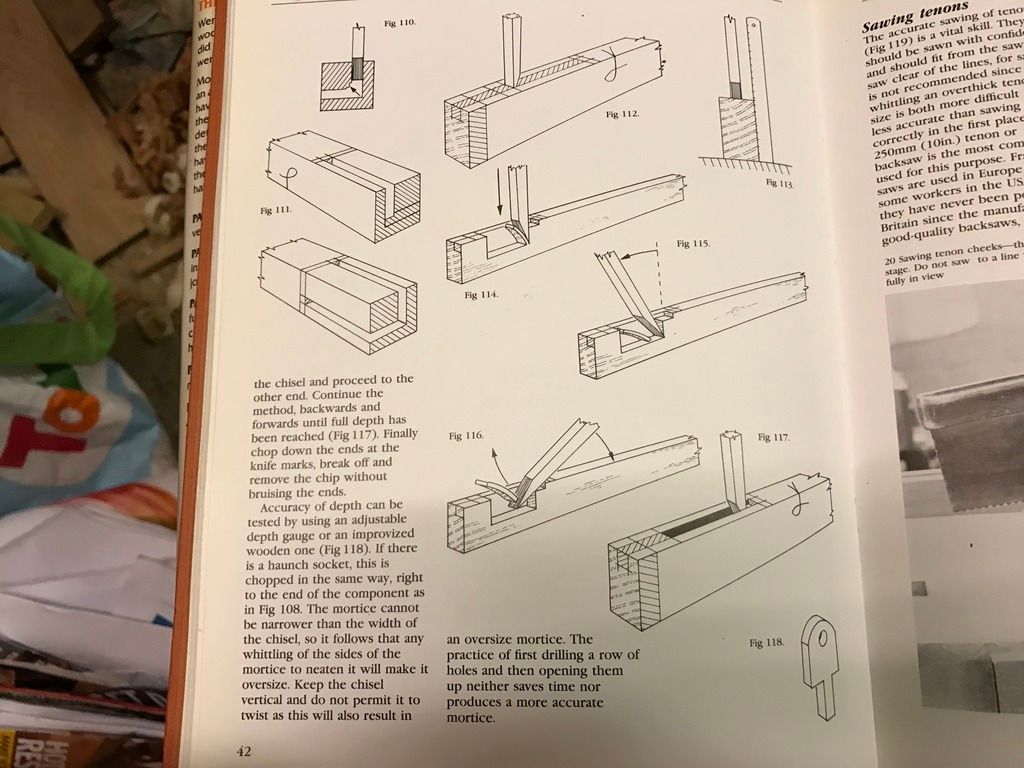

I think Wearing was referring to chain drilling being unnecessary, which isn't the same as drilling one relief hole for the waste to fall away. Chain drilling is a waste of time if the mortice is to be chopped with mortice chisels. A single relief hole does have a useful purpose. It may not be necessary for some people, but then again if it enables an advantage for others, then it is a valid device.

Chain drilling, followed by paring with a bench chisel, similarly is useful for making mortices that are out if the ordinary. My bench for example, had massive through mortices. Something in the order of 4 1/2 inches long, 1 1/4 wide into 4 by 4 stock. Chain drilling was my preferred method then!

What Jacob has trouble in understanding, versatility is not a weakness. We can do things in many ways and get the right result, and we can do things differently than how we were taught. The teachers give us a starting point from which we advance from, not dogmatically follow the 'rules'. It is a Japanese adage that says, it is a poor master, who's student does not better him. I expect Jacob's teacher might be a bit disappointed.

Mike.