Nigel Taylor

Established Member

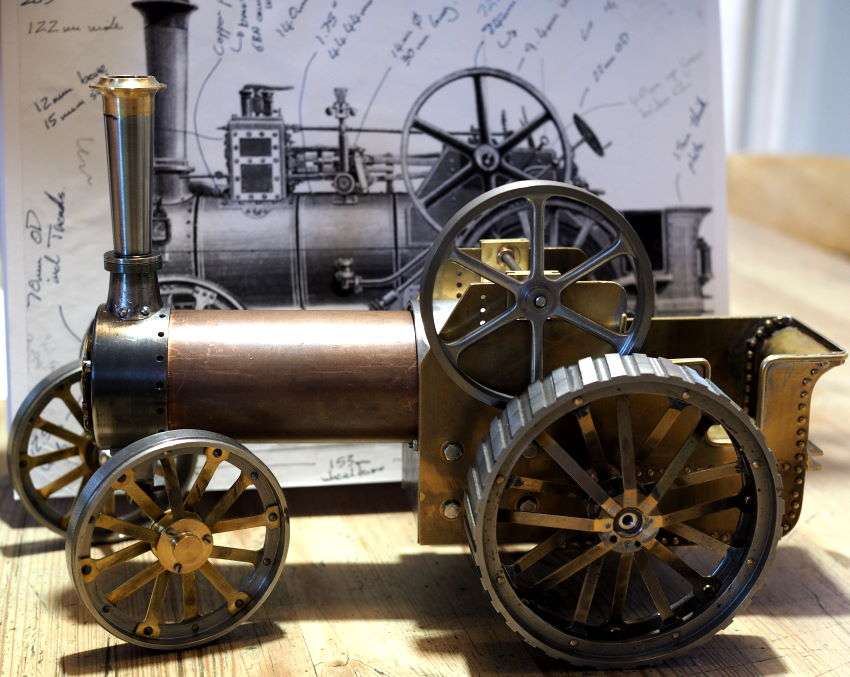

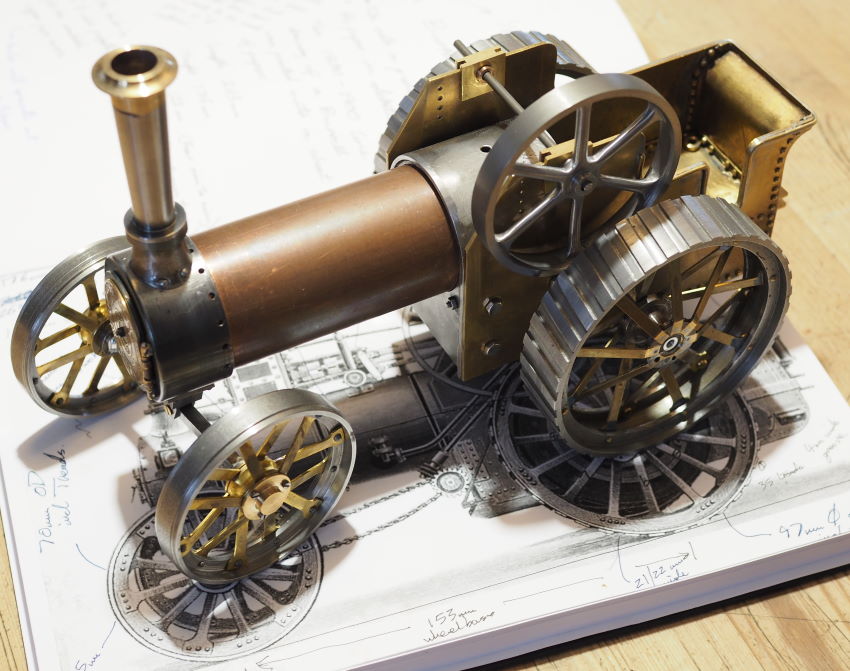

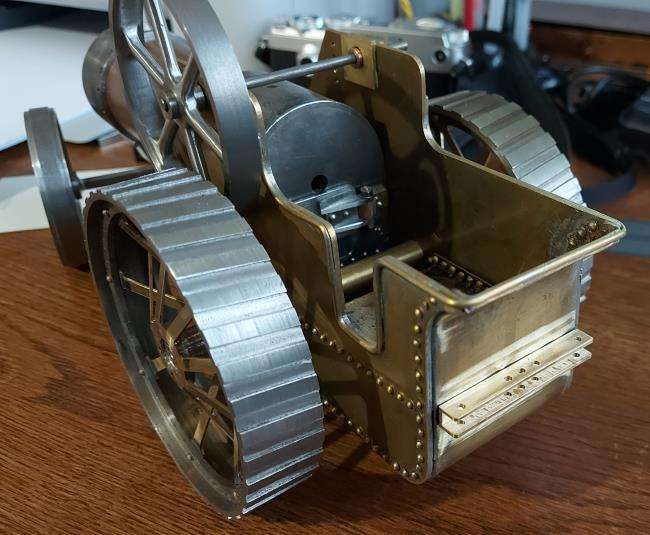

I made a flywheel for the Burrell from solid cast iron, but it looked too heavy

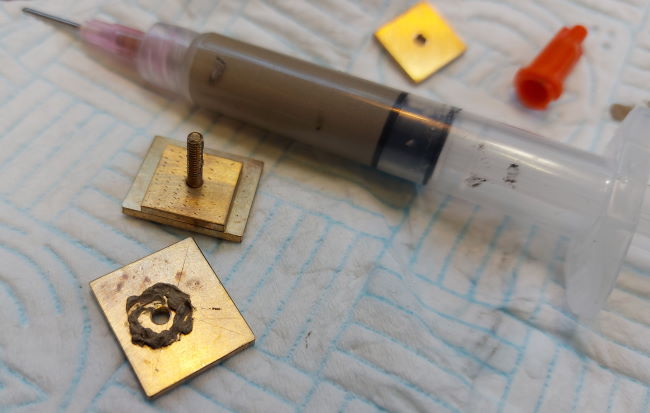

so, back to the lathe and some more machining and then some milling. Finally some hand belt sanding to get to this

I created a narrated video to show the simple steps to machining this from solid

so, back to the lathe and some more machining and then some milling. Finally some hand belt sanding to get to this

I created a narrated video to show the simple steps to machining this from solid