MikeG.

Established Member

bugbear":1r88wzx4 said:......Werner Heisenberg says it's impossible. There is a big conceptual gap between very small and zero......

They're wrong too.

What is so special about 90 degrees which makes it impossible to achieve? 89.99999999999999 is possible, 90.00000000001 is possible. Why not 90?

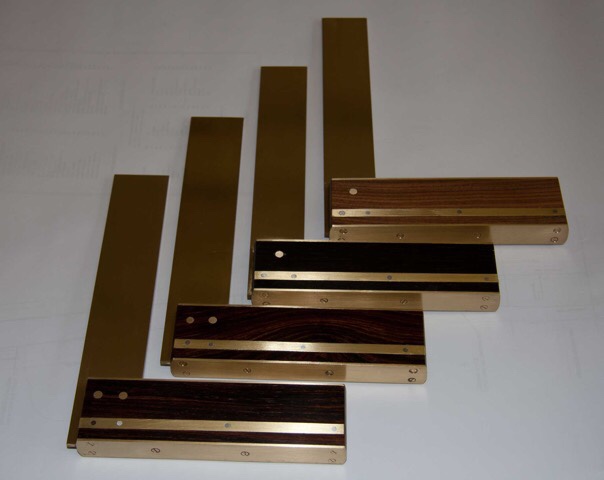

I am making a point about logic and the precision of language, not about the precision of squares. If I went out to the workshop and made 10 squares out of wood, they'd likely all be different, but there is no reason on this planet why one (or more) of them might not fluke exactly 90 degrees. (Of course, I would have no way of knowing whether I'd achieved this or not).

I fully understand the point you are trying to make: that manufacturing X number of squares and guaranteeing they'll all be 90 degrees is impossible. I agree with this: it is impossible. But that isn't actually what you said.