RobertMP

Established Member

Finally getting round to starting on 2 items to compliment the sideboard I made last year. Nothing difficult or unusual about them but I thought I might as well take some pictures as I go along

Both items are in Beech and will have the same gloss finish that we have grown to like on the sideboard.

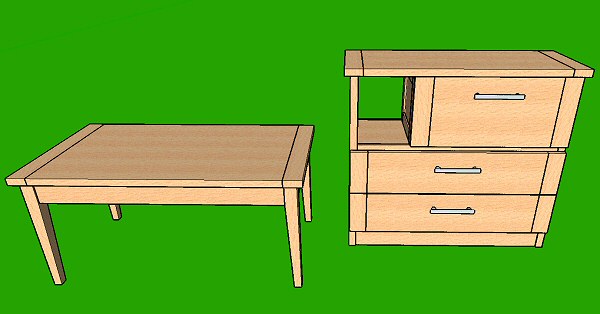

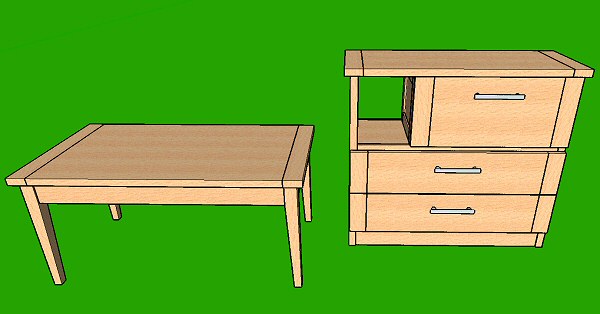

here is a screen cap. of the sketchup

The table is 900 x 500mm on the top and the cabinet top is 780 x 320mm. The space in the cabinet is to take a small hifi unit and there is no back on that part or the space along side. The top drawer face is a drop down flap to give access to the Ipod dock for the hifi and the usual CDs etc that tend to accumulate.

I searched various threads on here for clever drop down flap hinges and found a few options but the prices for a pair of hinges seemed ridiculously high - guess they would normally have huge trade discounts taken off. Anyway I adjusted the design so that I can use a simple plain hinge of some kind and some stays.

I'll update this thread as I go but I'm off for a holiday soon so there will be a break in proceedings

So having printed off reams of paper from sketchup I now have all my rough cutting done.

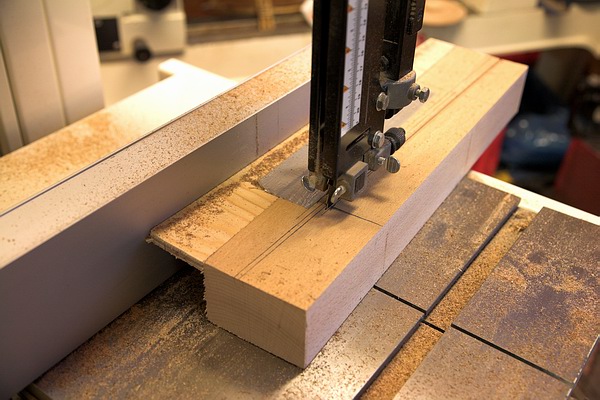

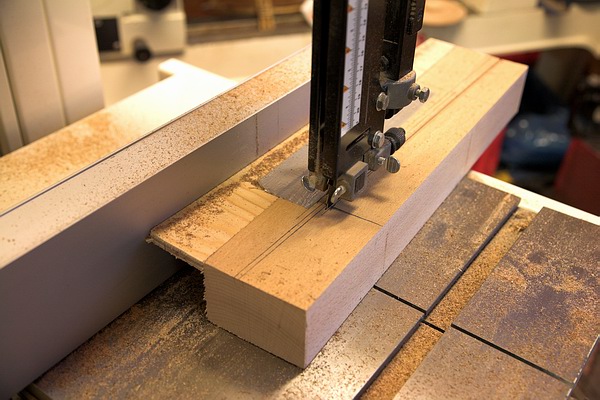

Wasn't sure how to go about the tapered legs. made a simple plywood wedge and taped it to the blank for 2 legs. Seemed to work. Bandsaw blade is starting to get tired now so cutting is slower than it should be. I'll get a decent make next time

I'll leave the second taper cut until I've squared the straight sides up.

Both items are in Beech and will have the same gloss finish that we have grown to like on the sideboard.

here is a screen cap. of the sketchup

The table is 900 x 500mm on the top and the cabinet top is 780 x 320mm. The space in the cabinet is to take a small hifi unit and there is no back on that part or the space along side. The top drawer face is a drop down flap to give access to the Ipod dock for the hifi and the usual CDs etc that tend to accumulate.

I searched various threads on here for clever drop down flap hinges and found a few options but the prices for a pair of hinges seemed ridiculously high - guess they would normally have huge trade discounts taken off. Anyway I adjusted the design so that I can use a simple plain hinge of some kind and some stays.

I'll update this thread as I go but I'm off for a holiday soon so there will be a break in proceedings

So having printed off reams of paper from sketchup I now have all my rough cutting done.

Wasn't sure how to go about the tapered legs. made a simple plywood wedge and taped it to the blank for 2 legs. Seemed to work. Bandsaw blade is starting to get tired now so cutting is slower than it should be. I'll get a decent make next time

I'll leave the second taper cut until I've squared the straight sides up.