Hi Guys,

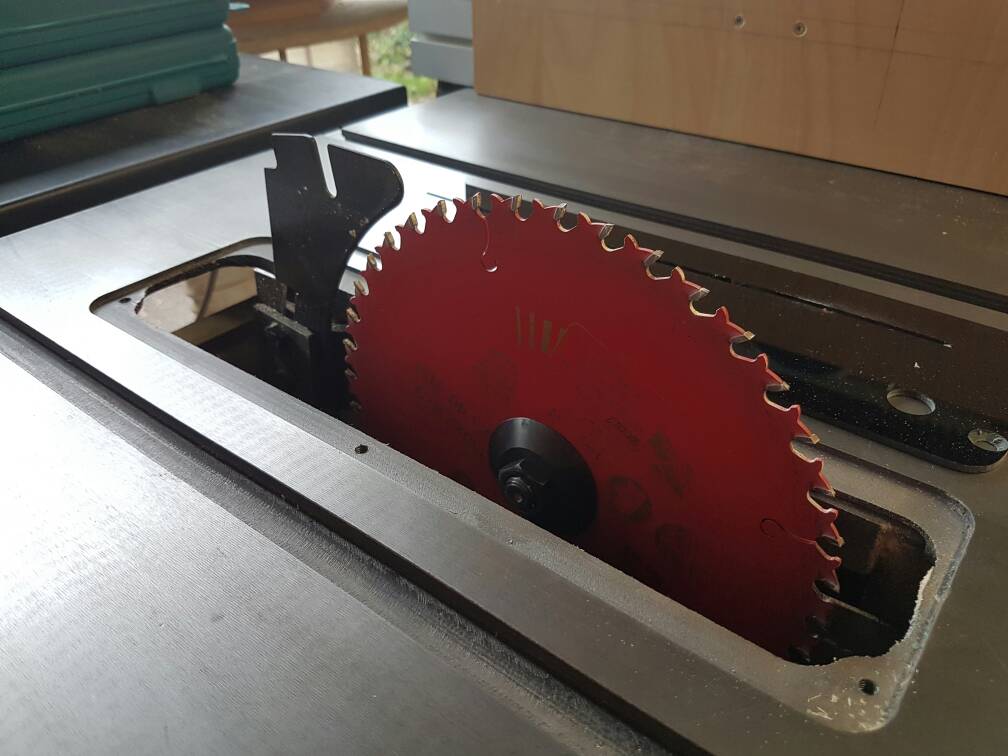

I've only just gotten my AW10 (i only went for the basic model due to my budget), and to be honest i probably should have a done a little more research when it came to the blade/guard/knife setup.

It seems like a great saw, but the plans in my head to build a crosscut sled, and cutting grooves etc don't seem to be possible with the riving knife above the blade height / the guard in the way.

What have you guys done? - I do very much want to keep the saw as safe as possible and utilise these features, Do you think a crosscut sled without the rear fence would work? I was thinking of something like Nick Ferrys sled design (https://nickferry.com/2015/07/table-saw ... -one-ep58/)

I don't suppose anyones knows if axminster sell replacement riving knives? I cut could the height down to be flush with the blade height... but how to ask axi if they do without obviously side stepping "intended use" i'm not really sure

Thoughts, or suggestions?

Thanks as always!

I've only just gotten my AW10 (i only went for the basic model due to my budget), and to be honest i probably should have a done a little more research when it came to the blade/guard/knife setup.

It seems like a great saw, but the plans in my head to build a crosscut sled, and cutting grooves etc don't seem to be possible with the riving knife above the blade height / the guard in the way.

What have you guys done? - I do very much want to keep the saw as safe as possible and utilise these features, Do you think a crosscut sled without the rear fence would work? I was thinking of something like Nick Ferrys sled design (https://nickferry.com/2015/07/table-saw ... -one-ep58/)

I don't suppose anyones knows if axminster sell replacement riving knives? I cut could the height down to be flush with the blade height... but how to ask axi if they do without obviously side stepping "intended use" i'm not really sure

Thoughts, or suggestions?

Thanks as always!