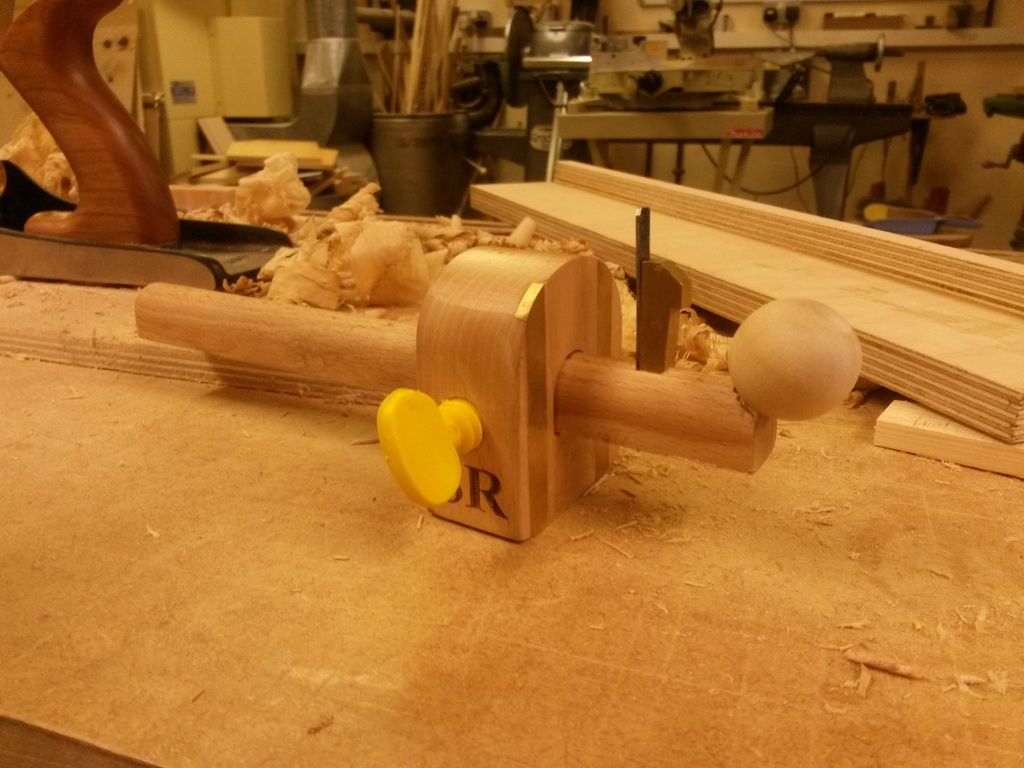

The elypses where marked with a compass and the holes where drilled with a flat bit in over thick stock, then cut down this stops any problem with break out on the back side. Then cut in the band saw and smoothed with a sander.

The wedge slot was marked and cut and paired to size, I prepared the rosewood for the wedges and cut out with the band saw and sander.

I purchased some maple dowel and cut it to length and plained a flat on them.

I have some 3mm silver steel for the knives they will be fitted into under sized holes.

So far a day and a halfs work as I was making jam this morning, 13 pots of plum lime and ginger.

Pete