woodbloke

Established Member

This is the start of a small box in the style of one's developed by Robert Ingham. I've just finished sawing the material for it:

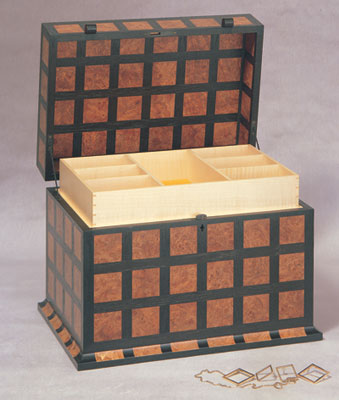

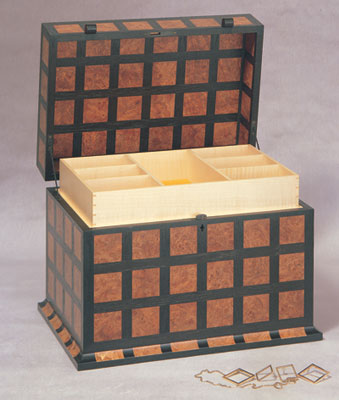

The carcass timber is going to be 9mm birch ply, with 3mm burr elm veneers over the top and on the inside of the lid. Each segment of the box will be made from squares of burr elm with African Ebony in between. The mahogany is the balancer veneer inside the box...it's not going to be seen. The burr elm bookmatched panel will be on the underside of the base. Difficult to describe, but it will be a much smaller version of:

...this sort of thing, with only 3 large squares (front) an 3 oblongs (lid) panels at the front. It's going to be a fairly complex build :shock: - Rob

The carcass timber is going to be 9mm birch ply, with 3mm burr elm veneers over the top and on the inside of the lid. Each segment of the box will be made from squares of burr elm with African Ebony in between. The mahogany is the balancer veneer inside the box...it's not going to be seen. The burr elm bookmatched panel will be on the underside of the base. Difficult to describe, but it will be a much smaller version of:

...this sort of thing, with only 3 large squares (front) an 3 oblongs (lid) panels at the front. It's going to be a fairly complex build :shock: - Rob