SawdustMaker

Established Member

Hi All,

I would like some constructive feedback on this small workshop project i have in mind. My project is to make a storage unit for 100 of these little green boxes as demonstrated by my little helper. The tubs will help me reach my inner nirvana for organisation of fixings and fiddly bits around the workshop.

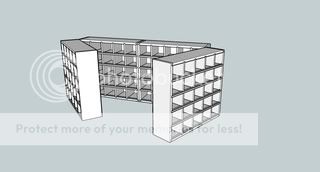

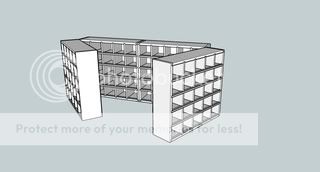

The location for the unit is the workshop so it does not have to be a masterpiece just functional and strong. As my workshop is only a standard garage wall space is at a premium so my plan was to construct something along the lines of the photo below, fixed to the workshop wall and having two hinged parts.

The outer carcase being made of 18mm plywood with the individual dividers out of say 12mm ply. The front would hinge open to reveal the remaining 50 tubs behind. The unit would be made of 4 identical sub units.

Overall the unit would take up 1.28m x 0.58m on the wall and be 346mm deep.

So to my questions.

1) Have I over engineered the carcase (18mm ply) / divider(12mm ply)

2) Does anyone foresee any issues with hinging the front units. I was planning to use normal steel butt hinges but did consider that perhaps a piano hinge would be better.

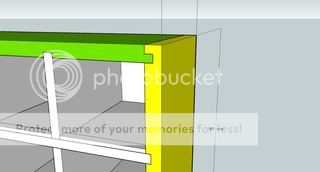

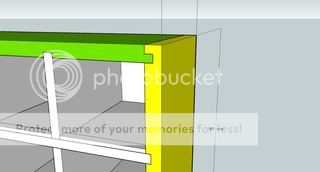

3) For the carcase corner joint. The following drawing shows a basic lock joint

My main concern here is the cantilever load on the carcase and figuring the lock joint is stronger and more resistant to racking due to the load. I also have a back on the unit made from say 3mm hardboard. To help with taking the load I intend to add supports to the underside of the fixed units so that they support the hinged part when closed (abit like door supports)

However at the same time I have considered just a butt joint with biscuits as this would be much faster than me having to rout out the lock joints.

Any comments / recommendations etc would be most welcome.

Thanks

I would like some constructive feedback on this small workshop project i have in mind. My project is to make a storage unit for 100 of these little green boxes as demonstrated by my little helper. The tubs will help me reach my inner nirvana for organisation of fixings and fiddly bits around the workshop.

The location for the unit is the workshop so it does not have to be a masterpiece just functional and strong. As my workshop is only a standard garage wall space is at a premium so my plan was to construct something along the lines of the photo below, fixed to the workshop wall and having two hinged parts.

The outer carcase being made of 18mm plywood with the individual dividers out of say 12mm ply. The front would hinge open to reveal the remaining 50 tubs behind. The unit would be made of 4 identical sub units.

Overall the unit would take up 1.28m x 0.58m on the wall and be 346mm deep.

So to my questions.

1) Have I over engineered the carcase (18mm ply) / divider(12mm ply)

2) Does anyone foresee any issues with hinging the front units. I was planning to use normal steel butt hinges but did consider that perhaps a piano hinge would be better.

3) For the carcase corner joint. The following drawing shows a basic lock joint

My main concern here is the cantilever load on the carcase and figuring the lock joint is stronger and more resistant to racking due to the load. I also have a back on the unit made from say 3mm hardboard. To help with taking the load I intend to add supports to the underside of the fixed units so that they support the hinged part when closed (abit like door supports)

However at the same time I have considered just a butt joint with biscuits as this would be much faster than me having to rout out the lock joints.

Any comments / recommendations etc would be most welcome.

Thanks