carlb40

Established Member

Further to this thread

some-pre-toolbox-cabinet-wip-questions-t76029.html

Well i have been wanting to make a toolbox for a while, so i have decided to go ahead and start one. It will be for my door hanging / 2nd fix hand tools only.

I will be mainly using materials i already have. It is going to be just a plainish rectangular box, nothing too fancy.

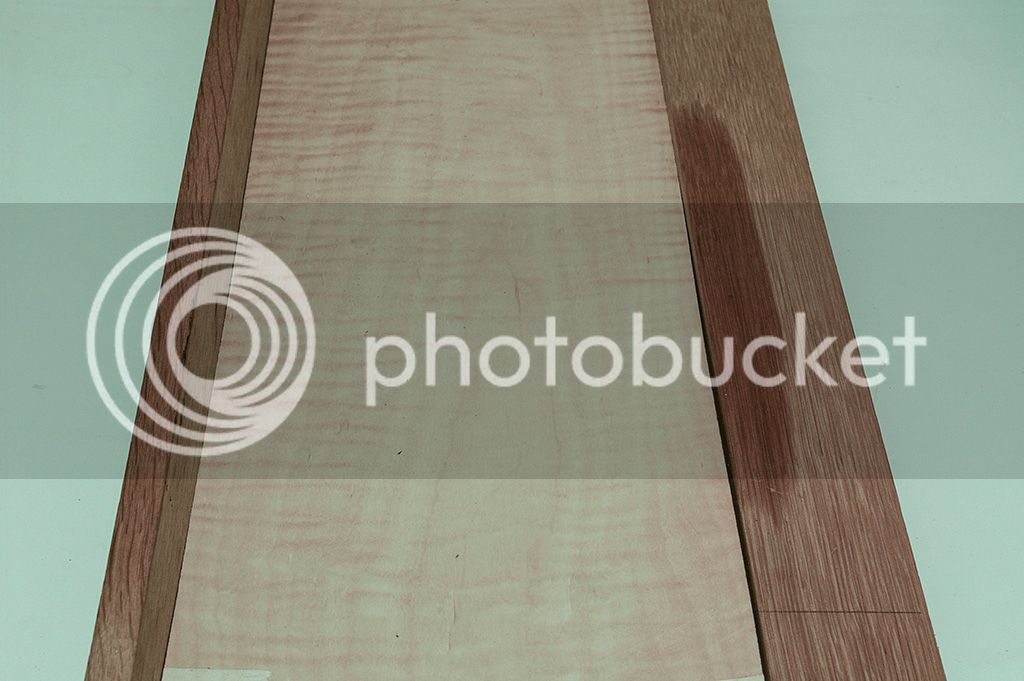

The main box will be 12mm hardwood exterior ply - acquired from a job last year. While not up there with birch ply, this stuff ( from travis perkins ) is quite good with very few voids.

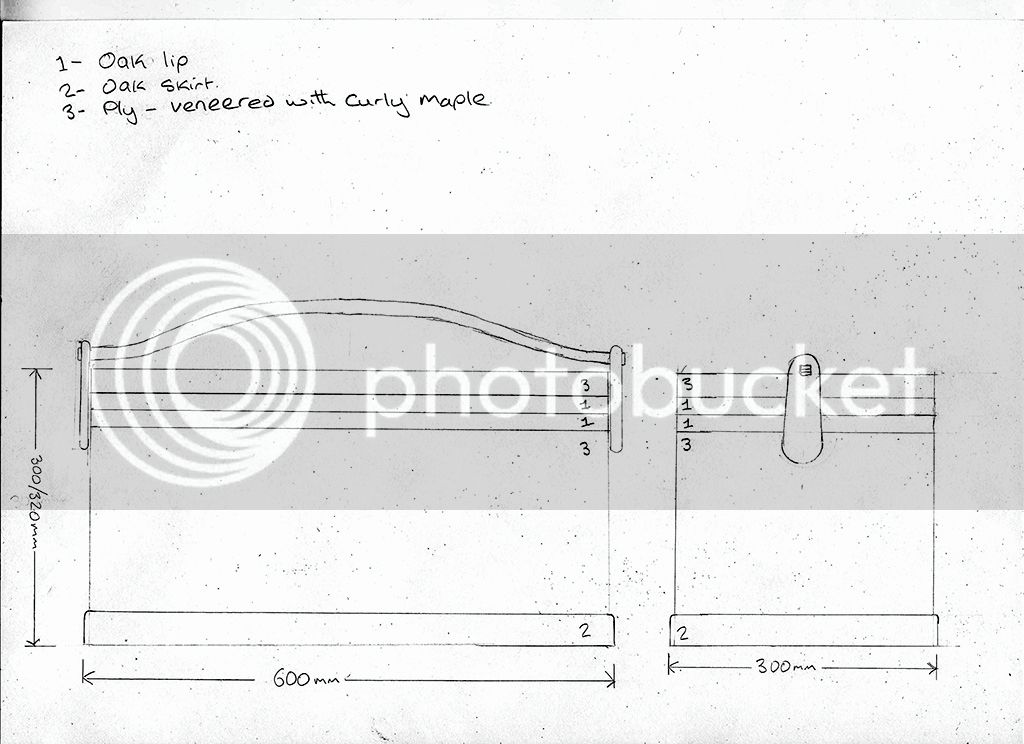

Any way the drawing of said box.

As you can see - starting at the bottom. It will have an oak skirt to give some protection to the bottom.

Then the ply - yet to be veneered - This will be my first time veneering. :shock:

Then we have 2 lots of oak lips again for decoration/ protection.

Then a bit more veneered ply to form a lid.

One detail not shown on the drawing. The corners will be mitred and reinforced with biscuits. Then further reinforced with dovetail splines.

The handle will be a curved contrasting hardwood, through wedged tenoned into the hardwood tear drop shaped pivots on the box sides.

Inside will be a lift out tray -made from solid oak. Mainly for the various marking/measuring tools.

Some details still need to be worked out. Hardware is still to be decided on.

If anyone can see any glaring issues please mention them.

EDIT

After popping down to the workshop and looking at the full size profile drawing, The height of the box will actually be around 260/265mm not the 300/320mm shown in the drawing.

some-pre-toolbox-cabinet-wip-questions-t76029.html

Well i have been wanting to make a toolbox for a while, so i have decided to go ahead and start one. It will be for my door hanging / 2nd fix hand tools only.

I will be mainly using materials i already have. It is going to be just a plainish rectangular box, nothing too fancy.

The main box will be 12mm hardwood exterior ply - acquired from a job last year. While not up there with birch ply, this stuff ( from travis perkins ) is quite good with very few voids.

Any way the drawing of said box.

As you can see - starting at the bottom. It will have an oak skirt to give some protection to the bottom.

Then the ply - yet to be veneered - This will be my first time veneering. :shock:

Then we have 2 lots of oak lips again for decoration/ protection.

Then a bit more veneered ply to form a lid.

One detail not shown on the drawing. The corners will be mitred and reinforced with biscuits. Then further reinforced with dovetail splines.

The handle will be a curved contrasting hardwood, through wedged tenoned into the hardwood tear drop shaped pivots on the box sides.

Inside will be a lift out tray -made from solid oak. Mainly for the various marking/measuring tools.

Some details still need to be worked out. Hardware is still to be decided on.

If anyone can see any glaring issues please mention them.

EDIT

After popping down to the workshop and looking at the full size profile drawing, The height of the box will actually be around 260/265mm not the 300/320mm shown in the drawing.