woodbloke

Established Member

Further to the recent thread on flattening plane backs and Alf's excellent demo at the MiniBash last Saturday, I decided to have a go at Alf's method. She used a piece of 10mm acrylic plastic onto which was smeared a small quantity of 45g diamond paste, mixed with a little paraffin to form slurry. The idea is that the slurry embeds itself to a certain extent into the much softer surface of the acrylic and doesn't 'ooze' out the sides, as it may do with much harder float glass, and also doesn't break down.

I tried a slightly different tack in that I screwed a piece of 6mm acrylic to a bit of 15mm mdf and then bearing cut off the waste with the router. I then used coarse Silicon Carbide valve grinding paste (which is very fast cutting, much faster I think than the diamond that Alf was using.) After a few minutes pressure tho' this then breaks down into a much finer slurry and gives a smoother finish. I then wiped the old coarse slurry off the surface and replaced it with some fine valve grinding paste and repeated the process. After about 10 minutes total with the valve grinding paste it was onto the coarse DMT for a couple of mins to finish off.

This first pic shows one side of a blade with the tempering colours done by Newt a few weeks ago:

-

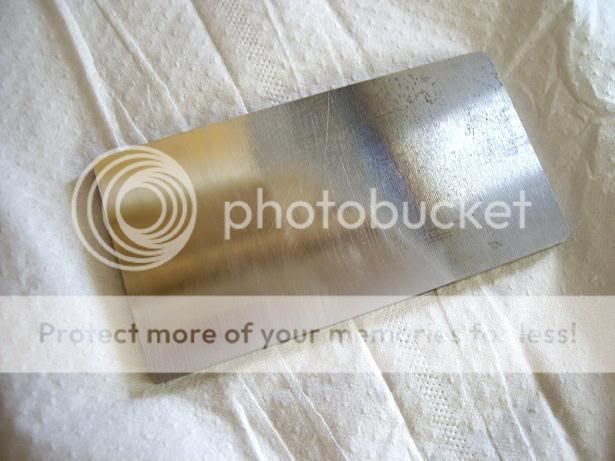

The shot above shows the polished back after about 12 minutes or so, it's certainly good enough to start grinding the primary bevel on the other side and then the 'ruler trick' to finish off. I'm not sure that the coarse paste wasn't a little too brutal to start with, but it's an interesting way to do the backs and very quick - Rob

I tried a slightly different tack in that I screwed a piece of 6mm acrylic to a bit of 15mm mdf and then bearing cut off the waste with the router. I then used coarse Silicon Carbide valve grinding paste (which is very fast cutting, much faster I think than the diamond that Alf was using.) After a few minutes pressure tho' this then breaks down into a much finer slurry and gives a smoother finish. I then wiped the old coarse slurry off the surface and replaced it with some fine valve grinding paste and repeated the process. After about 10 minutes total with the valve grinding paste it was onto the coarse DMT for a couple of mins to finish off.

This first pic shows one side of a blade with the tempering colours done by Newt a few weeks ago:

-

The shot above shows the polished back after about 12 minutes or so, it's certainly good enough to start grinding the primary bevel on the other side and then the 'ruler trick' to finish off. I'm not sure that the coarse paste wasn't a little too brutal to start with, but it's an interesting way to do the backs and very quick - Rob