As Mike had pointed out, you seem to be looking for confirmation more than critical review.

Putting the stop a few mm away from the pivot creates the most force on the smallest area, so is asking for a failure. Just because someone has done it, doesn’t mean it’s right, and a CE Mark doesn’t mean it’s tested for all eventualities.

A cord at the bottom of the triangle is the easiest option but I would never recommend it, as with a bit of slack you’ve created a ligature, not a good thing to have around little ones.

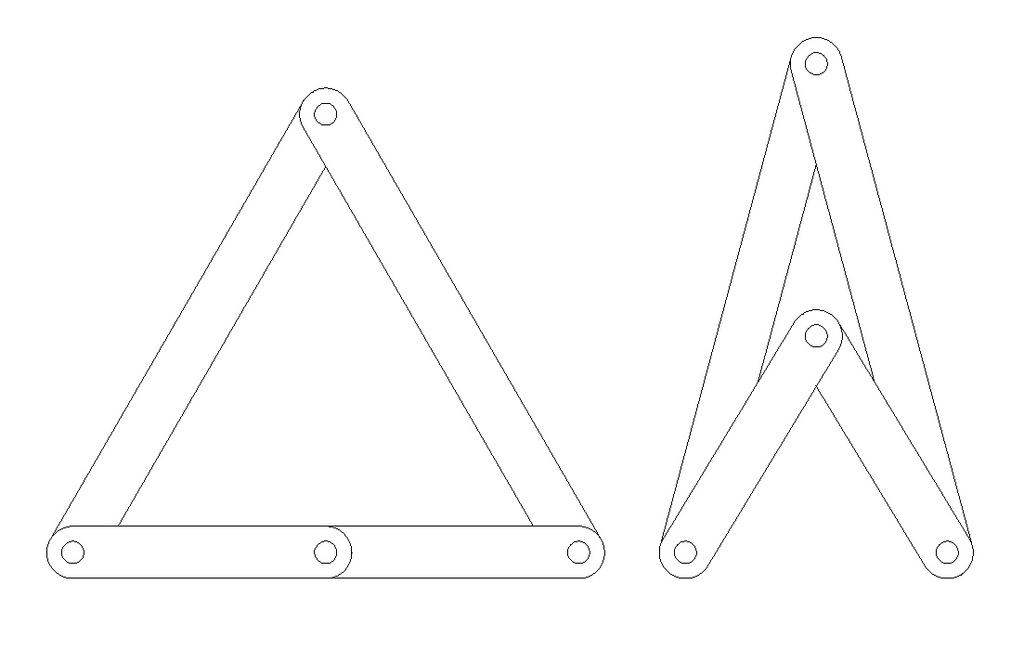

Mike’s bi-folding link could be quite elegant if you planned it well, or use the quadrant approach as also described.

Never pivot on a screw, but using a ground steel shoulder screw against wood is going to result in one of those materials coming off worse. Increase diameter to increase area and reduce pressure.

Aidan