Has anyone made a zero-clearance throat plate for the Axminster TS200 table saw? The fitted plate is only 3mm thick, what material would be most suitable? As the existing plate is fitted on one side of the blade only does any allowance need to be made for the "gap" on the other side as there is no ledge to rest the plate on? The plate leveling is very high-tec (you insert shim washers under the screws). I'm now off to Westonbirt for a long weekend so will respond on my return.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zero-clearance throat plate Axminster TS200

- Thread starter brianhr

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SammyQ

Established Member

Me too. Woodbloke showed me a cracking one he had made for his Kity 419 (parent genetic material for TS200 etc) but my geriatric cerebral ROM does not recall if his aluminium top was as thin as our Axy-wotsits cast iron ones are. Rob, if you're reading this, could you please spare a few mins to comment?

Sam

Sam

Steve Maskery

Established Member

I've not seen it so I may be talking bovine colonic waste here, but 3mm does not seem very thick to me for a throat plate.

Can you not make it out of 9mm MDF and rout a rebate to leave 3mm just at the edges? That would increase its strength no end.

S

Can you not make it out of 9mm MDF and rout a rebate to leave 3mm just at the edges? That would increase its strength no end.

S

SammyQ

Established Member

"bovine colonic waste"

Yay! Steve's joined the Civil Service! No criminological inexactitde!

Yay! Steve's joined the Civil Service! No criminological inexactitde!

Mr Ed

Established Member

I've been meaning to make a ZCI for my Kity 419 for years, but never got round to it. Partly for the reason stated, that there is so little material to the left of the blade I can't quite see it working;

A close up pic of Robs solution would be helpful.

Ed

A close up pic of Robs solution would be helpful.

Ed

Steve Maskery

Established Member

Ed

Apart from the fact that it is a mirror image of yours, mine is the same in that there is very little material to one side of the blade, yet I use ZCIs all the time. It's not really any different to one that is more evenly balanced. It's more fragile, I'll grant you, but I make up half a dozen at a time. Each one can be turned round when it gets worn out so a batch lasts for ages.

Cheers

steve

Apart from the fact that it is a mirror image of yours, mine is the same in that there is very little material to one side of the blade, yet I use ZCIs all the time. It's not really any different to one that is more evenly balanced. It's more fragile, I'll grant you, but I make up half a dozen at a time. Each one can be turned round when it gets worn out so a batch lasts for ages.

Cheers

steve

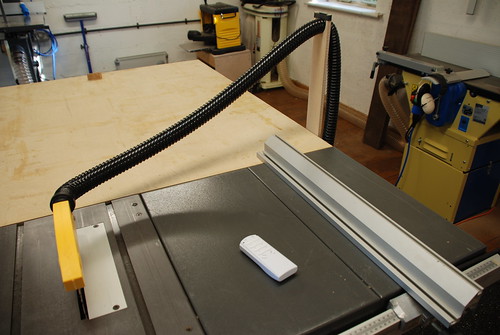

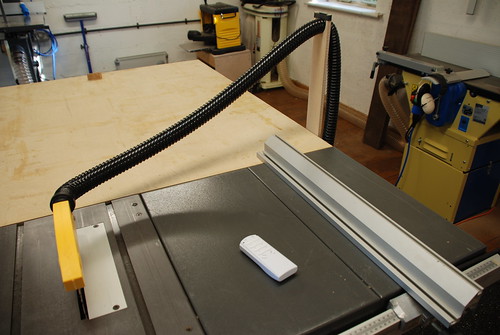

Hi - I made one for my axi TS 200 a couple of weeks ago as per instructions elsewhere on this fine forum:

3mm aluminium from e.bay

hacksaw and file to shape

drill holes and countersink

bring blade up slowly through with something over the top to stop red hot swarf flying everywhere

Points to note:

remember which way up it goes when countersinking as the holes are not symmetrical (at least not on mine - Doh!)

Check the blade is aligned and will not need moving after you've cut the slot (mine was too far to one side and so couldn't move to 45 degrees position and so needs moving over and so my slot is in the wrong position - grrr) I need to make another one.

I was worried about the thin edge and that the fixings are only on one side and thought it might 'chatter' when the blade went through and catch and bind so I clamped a bit of wood over the top to sort of support it and stop it moving - at least in one direction - but i'm not sure it was needed.

I didn't feel the MDF option was a goer as three mm of mdf isn't much and the 'ledge' is not a clean and regular shape so a pain to match to.

having done all that it did seem to work although the blade seemed to cut extra bits out of the aluminium depending on its height which makes me suspect it's not quite true somewhere.

Hope that helps

3mm aluminium from e.bay

hacksaw and file to shape

drill holes and countersink

bring blade up slowly through with something over the top to stop red hot swarf flying everywhere

Points to note:

remember which way up it goes when countersinking as the holes are not symmetrical (at least not on mine - Doh!)

Check the blade is aligned and will not need moving after you've cut the slot (mine was too far to one side and so couldn't move to 45 degrees position and so needs moving over and so my slot is in the wrong position - grrr) I need to make another one.

I was worried about the thin edge and that the fixings are only on one side and thought it might 'chatter' when the blade went through and catch and bind so I clamped a bit of wood over the top to sort of support it and stop it moving - at least in one direction - but i'm not sure it was needed.

I didn't feel the MDF option was a goer as three mm of mdf isn't much and the 'ledge' is not a clean and regular shape so a pain to match to.

having done all that it did seem to work although the blade seemed to cut extra bits out of the aluminium depending on its height which makes me suspect it's not quite true somewhere.

Hope that helps

lurker

Le dullard de la commune

Steve Maskery":2mt63q8b said:I've not seen it so I may be talking bovine colonic waste here, but 3mm does not seem very thick to me for a throat plate.

Can you not make it out of 9mm MDF and rout a rebate to leave 3mm just at the edges? That would increase its strength no end.

S

My TS is a completely different model but similar problem. I do much as Steve says.

Following Niki's advice I use a offcut of floor laminate which gives a smooth surface. I usually knock up 3-4 at a time - that lasts a year or more. The last one is template for next batch.

leighf

Established Member

Steve Maskery":3cen2mef said:Can you not make it out of 9mm MDF and rout a rebate to leave 3mm just at the edges? That would increase its strength no end.

S

I've just made a few of these today out of 9mm MDF, they are better than the big gap thats there with the supplied one.

Trying to stiffen one up abit, ones glueing up at the moment.

Similar threads

- Replies

- 7

- Views

- 392

- Replies

- 2

- Views

- 1K

- Replies

- 6

- Views

- 2K

- Replies

- 10

- Views

- 1K