Having a bench grinder for starters, it will make any chance for errors drastically reduce.

No excuses for not having one!.. they're dirt cheap, have an induction motor that will last forever.

Depending on how much camber you use, it may play a part in this, but for me what worked starting with my lightly cambered irons,

was honing with the blade sideways, facing the small bevel, honing to and away from me.

I could register at each end (corner) of the iron, instead of focusing on registering on the tippy hollow ground bevel.

The same principle as chopping mortises plum with a small square and a chisel,

In that you can see the bevel laying flat on the stone.

You cant really change the angle if your honing sideways, with not much camber.

By that, I mean creating a larger camber without wanting to....(nothing to do with your honing angle)

This gave me a new way of approaching sharpening, because I'm using a different method for reference now and it's a lot easier.

Imagine, like you were expecting someone to shake out your credit card with a vice grips either side of your hand,

Referencing on each end gives a different grasp to focus on and will aid muscle memory.

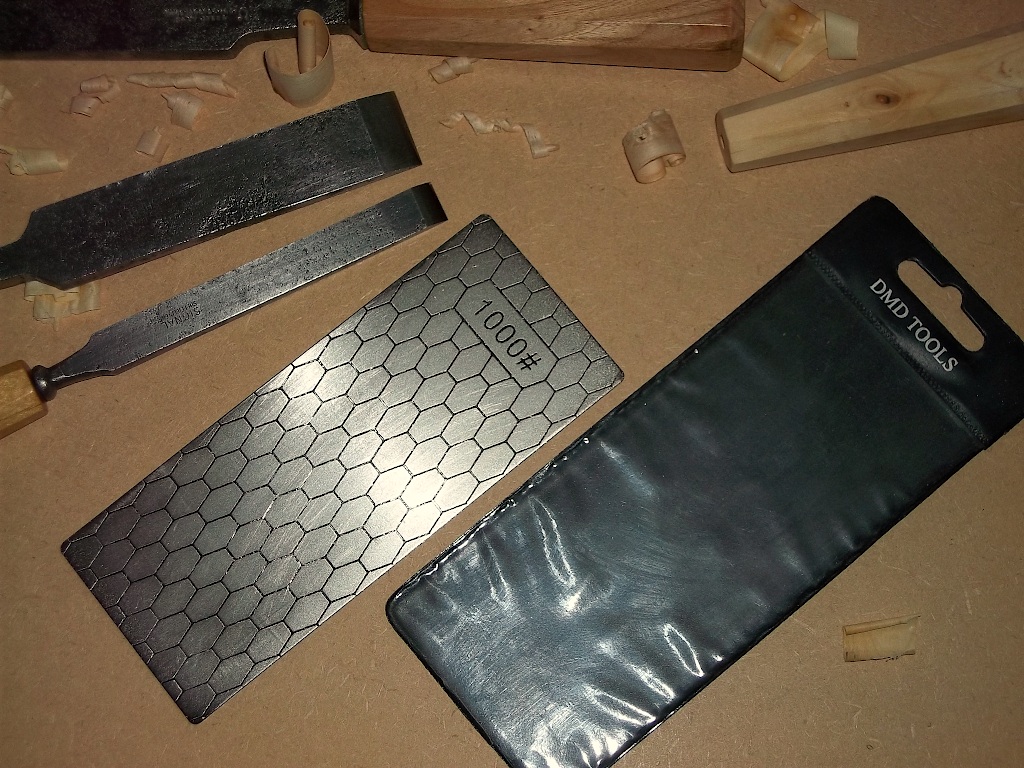

Two things about this method though.... if you have an oilstone, you will hollow it out, so it might be a good candidate for the diamond plates.

And it takes a larger amount of strokes to hone an edge.

I don't skew or hone sideways now, just normally like everyone else, but have retained the important part, the knowledge of where to focus and hold the iron and can do any pattern of honing with any camber without changing the bevel angle.

even honing on a high spot is no problem.

Looking at a lot of folks now, I can see that same stance.

Tom